PVC floor leather material and preparation method thereof

A floor leather and material technology, applied in the field of floor materials, can solve the problems of large floor leather stretchability and low use stability, and achieve stable performance, strong durability, and good application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

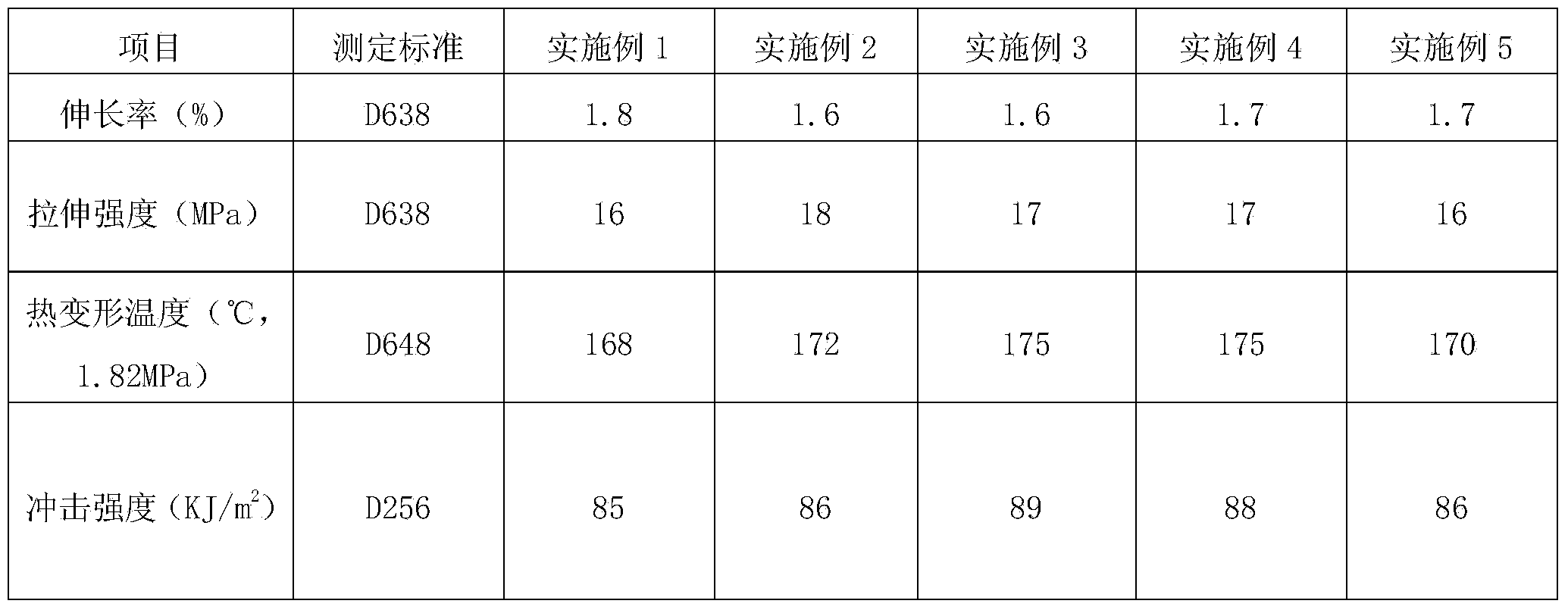

Examples

Embodiment 1

[0013] A PVC floor leather material, comprising by weight components: 80 parts of PVC, 15 parts of DOP, 10 parts of DBP, 5 parts of paraffin, 1 part of calcium-zinc composite stabilizer, 0.2 part of stearic acid, 0.5 part of barium stearate, trimethyl phosphate 5 parts of phenolic esters.

[0014] The PVC floor leather material described above is prepared according to the following steps:

[0015] (1) Weigh each component according to parts by weight;

[0016] (2) Mix the components in a mixing mixer, the stirring speed is 60 rpm, the stirring temperature is 50°C, and the stirring time is 20 minutes;

[0017] (3) The material mixed in step (2) is rolled by four-roller calendering, wherein the rolling speed is 5 m / min, and the temperature is 155°C.

Embodiment 2

[0019] A PVC floor leather material, comprising by weight components: 82 parts of PVC, 18 parts of DOP, 16 parts of DBP, 6 parts of paraffin, 2 parts of calcium-zinc composite stabilizer, 0.3 part of stearic acid, 0.6 part of barium stearate, trimethyl phosphate 7 parts of phenolic esters.

[0020] The PVC floor leather material described above is prepared according to the following steps:

[0021] (1) Weigh each component according to parts by weight;

[0022] (2) Mix the components in a mixing mixer, the stirring speed is 65 rpm, the stirring temperature is 52°C, and the stirring time is 25 minutes;

[0023] (3) The material mixed in step (2) is rolled by four-roller calendering, wherein the rolling speed is 6 m / min, and the temperature is 158°C.

Embodiment 3

[0025] A PVC floor leather material, comprising by weight components: 84 parts of PVC, 19 parts of DOP, 17 parts of DBP, 7 parts of paraffin, 3 parts of calcium-zinc composite stabilizer, 0.4 part of stearic acid, 0.7 part of barium stearate, trimethyl phosphate 8 parts of phenolic esters.

[0026] The PVC floor leather material described above is prepared according to the following steps:

[0027] (1) Weigh each component according to parts by weight;

[0028] (2) Mix the components in a mixing mixer, the stirring speed is 65 rpm, the stirring temperature is 58°C, and the stirring time is 23 minutes;

[0029] (3) The material mixed in step (2) is rolled by four-roller calendering, wherein the rolling speed is 7 m / min, and the temperature is 160°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat distortion temperature | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com