A kind of tackifier composition and application thereof for addition type silica gel

An addition type and tackifier technology, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of affecting the curing performance of the glue and poor versatility, and achieve simple use, good versatility, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

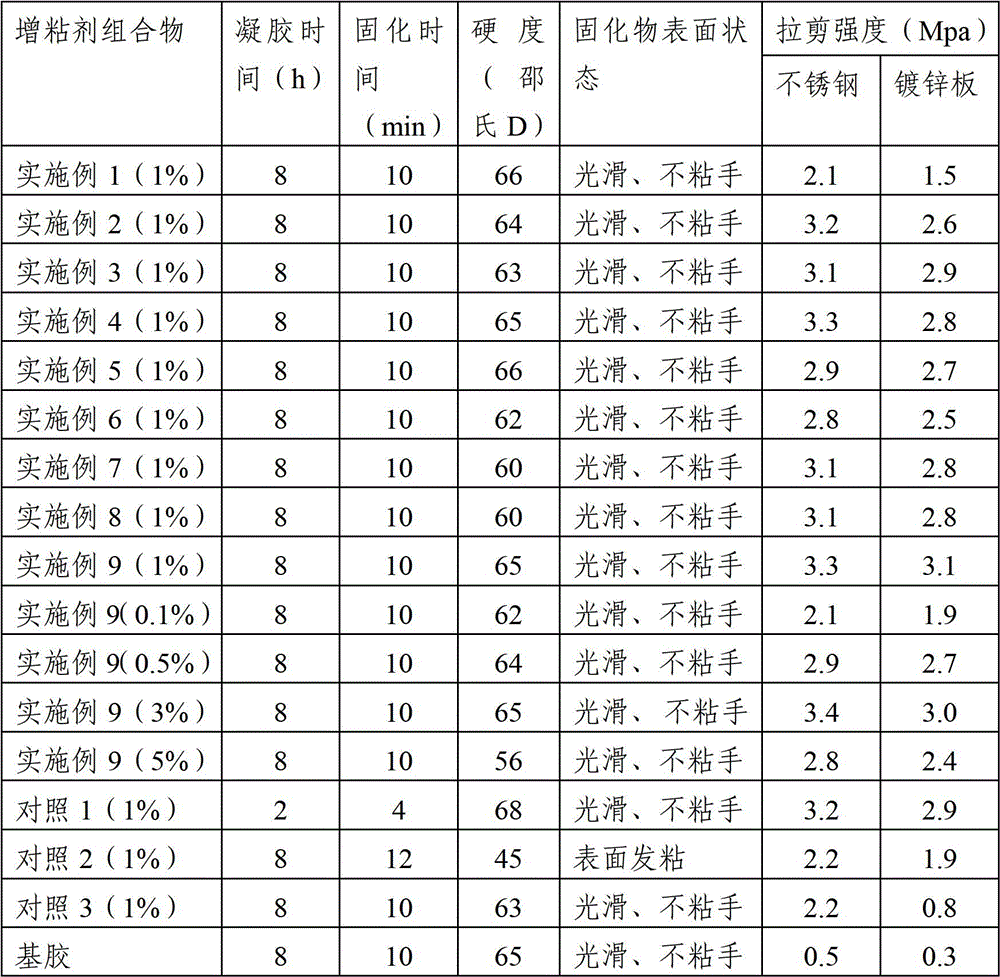

Examples

Embodiment 1

[0024] Embodiment 1 prepares tackifier composition of the present invention

[0025] To prepare the tackifier composition of the present invention, the raw materials are weighed in the following parts by weight:

[0026] KH560: 100g

[0027] Sulfonium salt: 0.01g

[0028] Mix well to obtain the tackifier composition of the present invention.

Embodiment 2

[0029] Embodiment 2 prepares tackifier composition of the present invention

[0030] To prepare the tackifier composition of the present invention, the raw materials are weighed in the following parts by weight:

[0031] KH560: 100g

[0032] Sulfonium salt: 0.1g

[0033] Mix well to obtain the tackifier composition of the present invention.

Embodiment 3

[0034] Embodiment 3 prepares tackifier composition of the present invention

[0035] To prepare the tackifier composition of the present invention, the raw materials are weighed in the following parts by weight:

[0036] KH560: 100g

[0037] Sulfonium salt: 1g

[0038] Mix well to obtain the tackifier composition of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com