A long-term corrosion-resistant and maintenance-free converter body-bottom seam construction method and its structure

A converter furnace body and corrosion-resistant technology, which is applied in the manufacture of converters, etc., can solve problems such as poor curing effect and accidents of molten steel passing through the furnace bottom seam, so as to improve safety and reliability, improve energy saving and efficiency effects, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

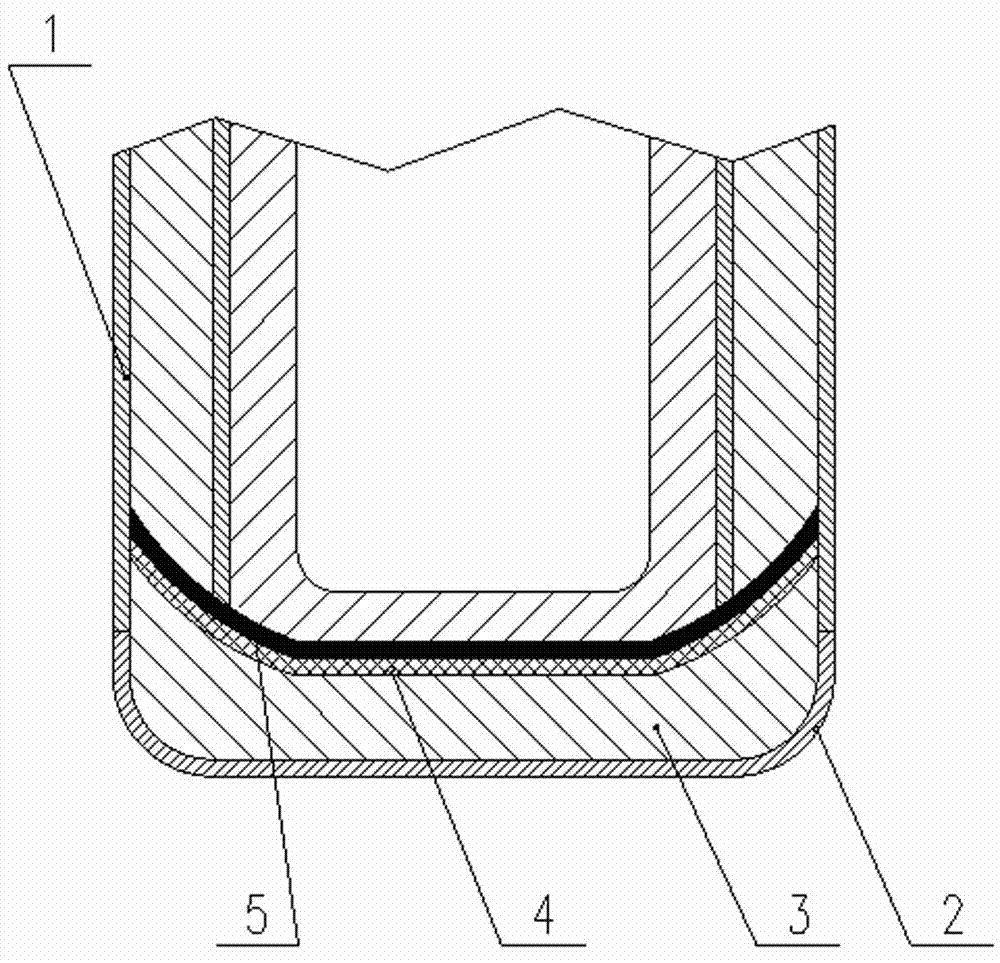

[0011] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way, and any changes or improvements based on the teaching of the present invention fall within the scope of protection of the present invention.

[0012] Such as figure 1 As shown, the method of the present invention includes foundation treatment, bottom net laying, specifically comprises the following steps:

[0013] A. Basic treatment: clean the surface of the furnace bottom, then lay the basic refractory material, and carry out surface treatment according to the process requirements;

[0014] B. Bottom net laying: Lay a layer of corrosion-resistant fixed reinforcement net on the treated foundation and fix it on the foundation;

[0015] C. Heat-resistant treatment: lay a high-temperature-resistant filler layer on the fixed reinforcement net, and lay a layer of refractory material on the filler layer;

[0016] D. Seam s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com