Electrolysis high temperature steam hydrogen production device and hydrogen production method

A high-temperature water vapor and hydrogen production device technology, applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of complex process, high cost, low hydrogen efficiency, etc., and achieve the effect of reducing cost and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

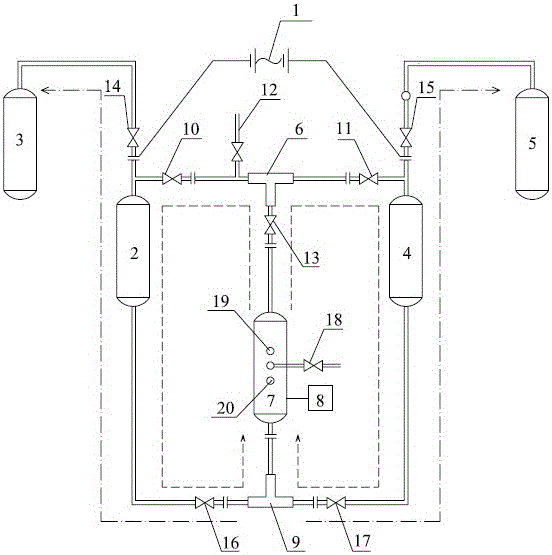

[0033] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure, the electrolysis high-temperature steam hydrogen production device includes a power supply 1, a H depolymerization kettle 2, a H 2 Collector 3, O Depolymerization kettle 4, O 2 Collector 5, heat conduction bridge 6, heat collector 7, heating furnace 8 and electrolytic bridge 9, wherein, power supply 1 connects H depolymerization kettle 2 and O depolymerization kettle 4 through electrodes, H depolymerization kettle 2 and H 2 collector 3 connection, O depolymerization tank 4 and O 2 Collector 5 is connected. The power supply provides current, and the electrolysis of sodium hydroxide aqueous solution produces hydrogen and oxygen, and the hydrogen is replaced by H 2 Collector collects, oxygen is collected by O 2 The collector collects. The role of the electrode is to fully contact with the sodium hydroxide aqueous solution to provide current to ensure sufficient electrolysis...

Embodiment 2

[0041] A method for producing hydrogen using an electrolytic high-temperature steam hydrogen production device, the method comprising the following steps:

[0042] (1) Heating: Start the heating furnace 8 to heat up the heat collector 7, and stop after the pipeline is filled with water vapor; as shown in the figure, the dotted arrow indicates the flow direction of water vapor, and the water vapor rises from the heat collector to After the heat conduction bridge, enter the H depolymerization kettle and the O depolymerization kettle on both sides, and then flow down to the electrolysis bridge. As a result, the pipeline is filled with water vapor. At this time, the heating step can be stopped and the electrolysis step can be entered;

[0043] (2) Electrolysis: close valve one 10, valve two 11, valve three 13, open the pressure relief port 12, and drain the water vapor in the heat conduction bridge, so that the heat conduction bridge forms a blocking insulation, therefore, the cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| specific heat capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com