Manufacturing method of steel skeleton structure

A manufacturing method and technology for structures, which can be applied in building structures, buildings, etc., can solve problems such as difficulty in obtaining sufficient load bearing capacity, easy bending of partitions, and many longitudinal gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

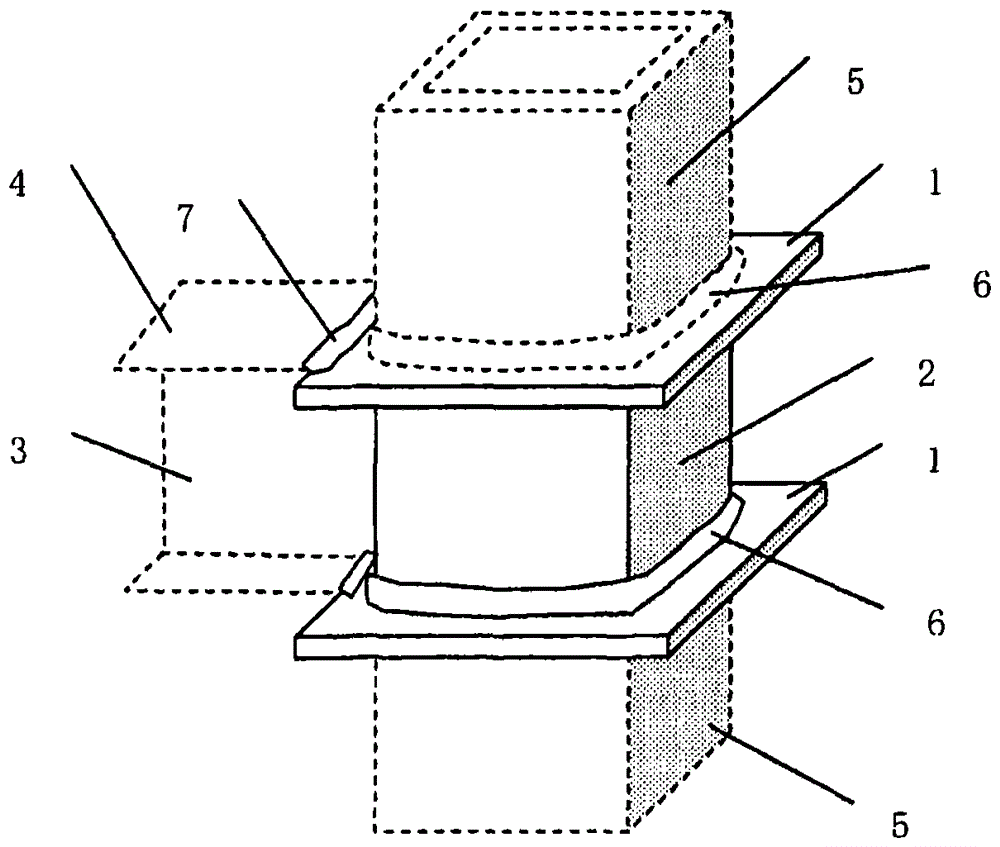

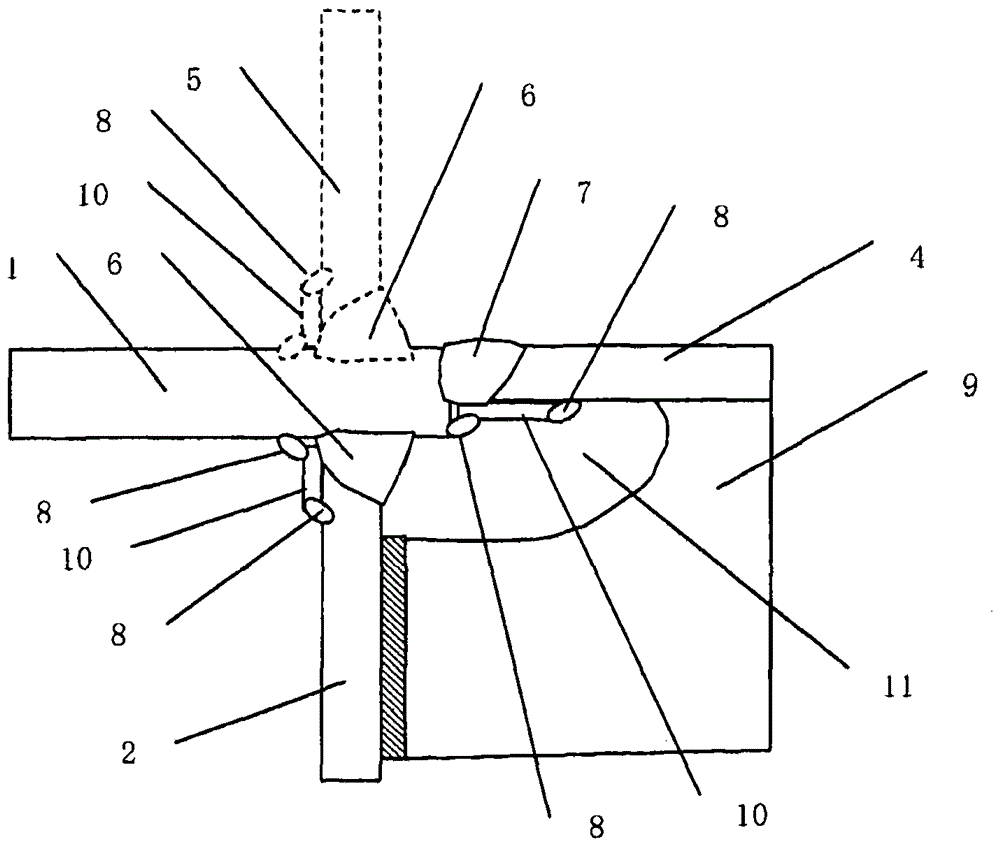

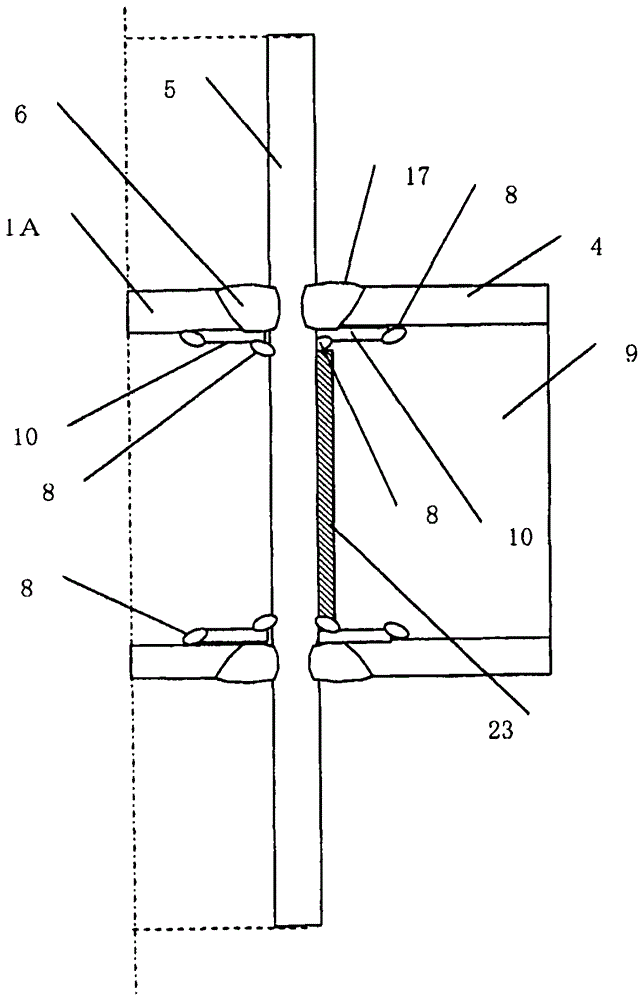

[0080] In the invention described in technical scheme 1, in Figure 11 to Figure 14 represents the state of implementation of the present invention. Figure 11 It is an explanatory diagram of the preparation status of the 4-sided box-shaped steel plate before assembling the 4-sided box-shaped steel pipe column, and the through-hole is opened in the column steel plate in advance. Figure 12 It shows the initial assembly state of installing the separator into the two sides of the steel plate for 4-sided box-shaped steel pipe. role of positioning. Figure 13 It is an intermediate assembly state in which the separator is incorporated into the 3 sides of the steel plate for the 4-sided box-shaped steel pipe, Figure 14 Indicates the state of intermediate assembly where separators are installed on the four sides of the steel plate for box-shaped steel pipes on four sides, and then, if the corners of the steel pipes with bevels are welded in the direction of the column axis, in add...

Embodiment 2

[0084] In the invention described in claim 1, for the purpose of welding stably from the outside of the column, it can be as follows Figure 10 As shown in an example of (A), a backing plate 10 is provided inside the through hole. In addition, if the backing plate 10 is attached in advance, it can also serve as a guide portion or a stopper for installing the partition plate 1A in the through hole.

Embodiment 3

[0086] Although the present invention has been described with respect to square steel pipes, it is also suitable for circular steel pipes. For example, if the circumference of a circular steel pipe is divided into a square steel pipe, it can be applied similarly to the square steel pipe. In this case, the circumferential welding of the circular steel pipe is divided into two at least in the axial direction of the welded joint, the plan view of the inner partition is circular, and the plan view of the end of the beam is an arc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com