Stair construction method through shaped supports

A technology of stereotyped support and construction method, which is applied to the preparation of stairs, formwork/formwork/work frames, and building components on site, and can solve problems such as difficult filling of concrete, affecting construction quality, and inconvenient construction of stairs. Good construction quality, convenient and fast construction, short installation and disassembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

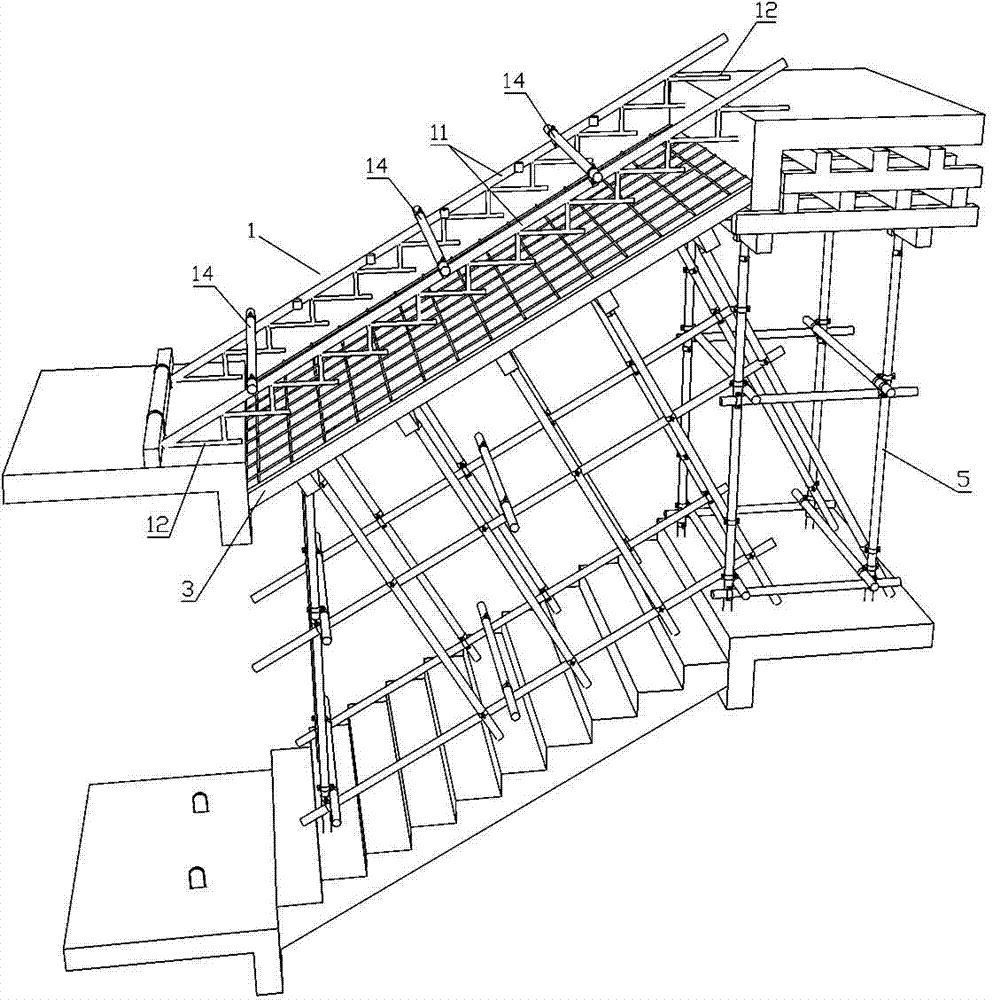

[0032] The present invention will be described in detail below with the stair construction against the wall on one side, that is, the stair construction at the stair position having only one free side.

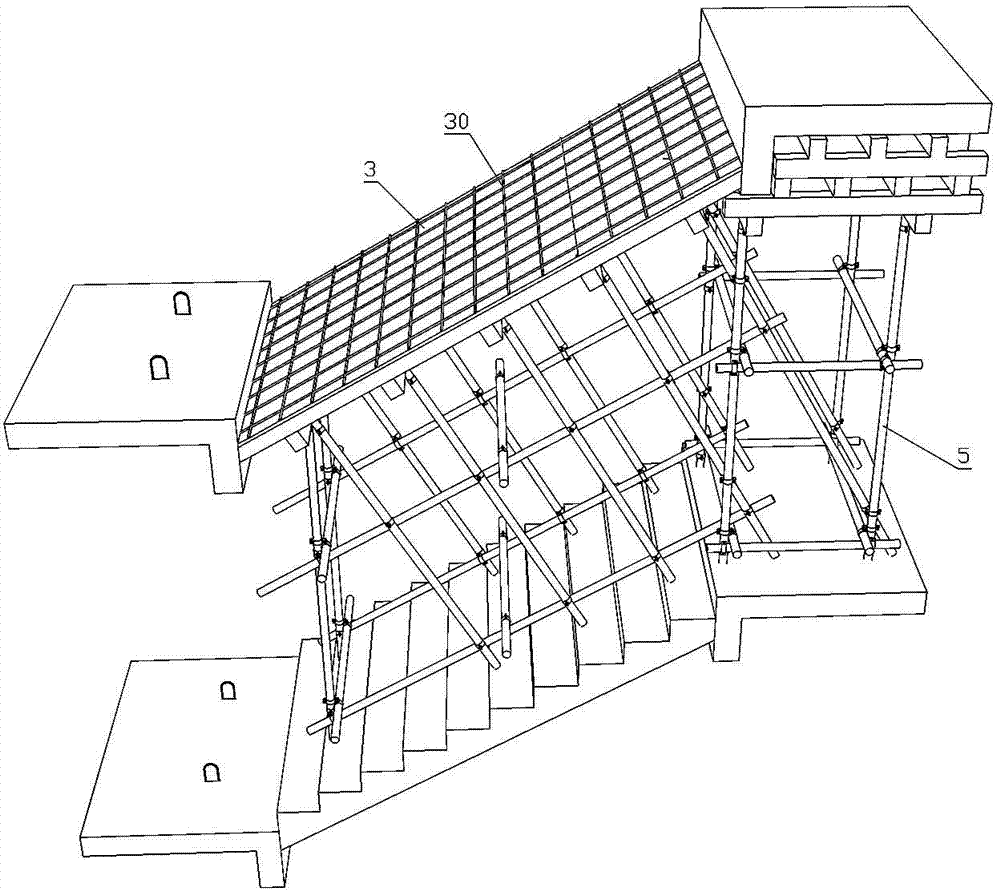

[0033] refer to Figure 1-Figure 5 , the construction method of shaped bracket stairs, comprising the following steps.

[0034] 1) Prepare stair shaping bracket 1, skirting board formwork 2, bottom formwork 3 and air side formwork 4;

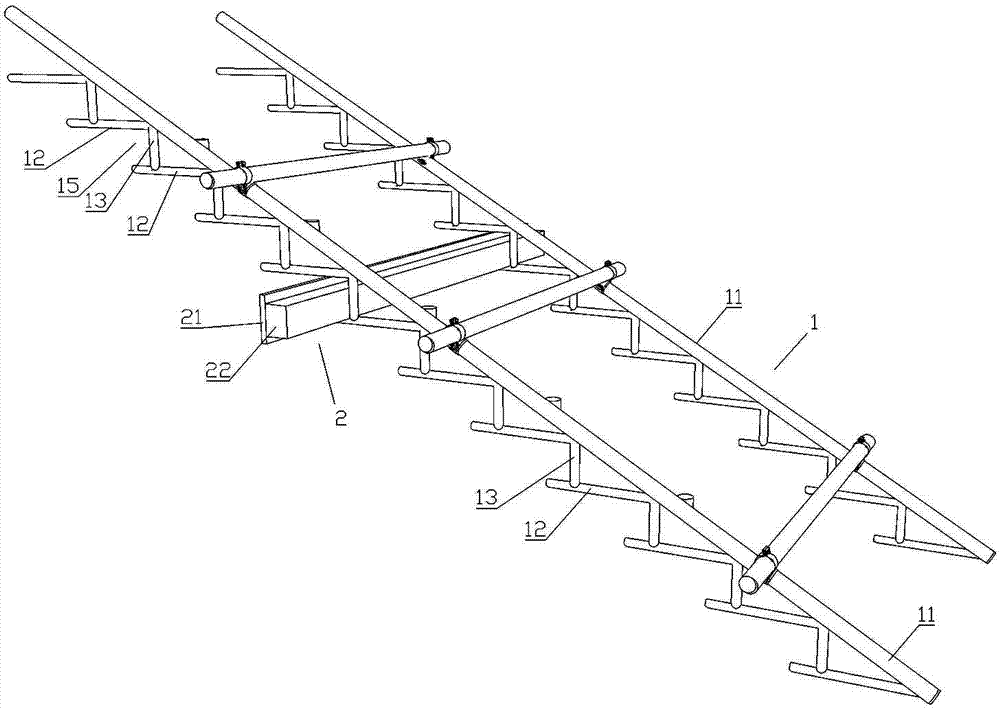

[0035] specific reference figure 1 , the stair shaping bracket 1 is welded by a long rod 11, several short horizontal rods 12 and several vertical short rods 13, and the ends of the short horizontal rods 12 are welded to the long rods 11 according to the inclination of the steps, namely The included angle of horizontal short bar 12 and long bar 11 is equal to the inclination of stair, and the height of design step is separated between every adjacent two horizontal short bars 12 and is vertically welded with a vertical short bar 13, vertical sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com