A high-altitude safety guardrail for steel structure installation and its manufacturing method

A technology of safety guardrail and manufacturing method, which is applied in building structure, processing of building materials, construction, etc., can solve the problems of hidden safety hazards, great influence of seat belts, lack of protection, etc., so as to avoid falling from a height, simple to manufacture, The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A high-altitude safety guardrail for steel structure installation

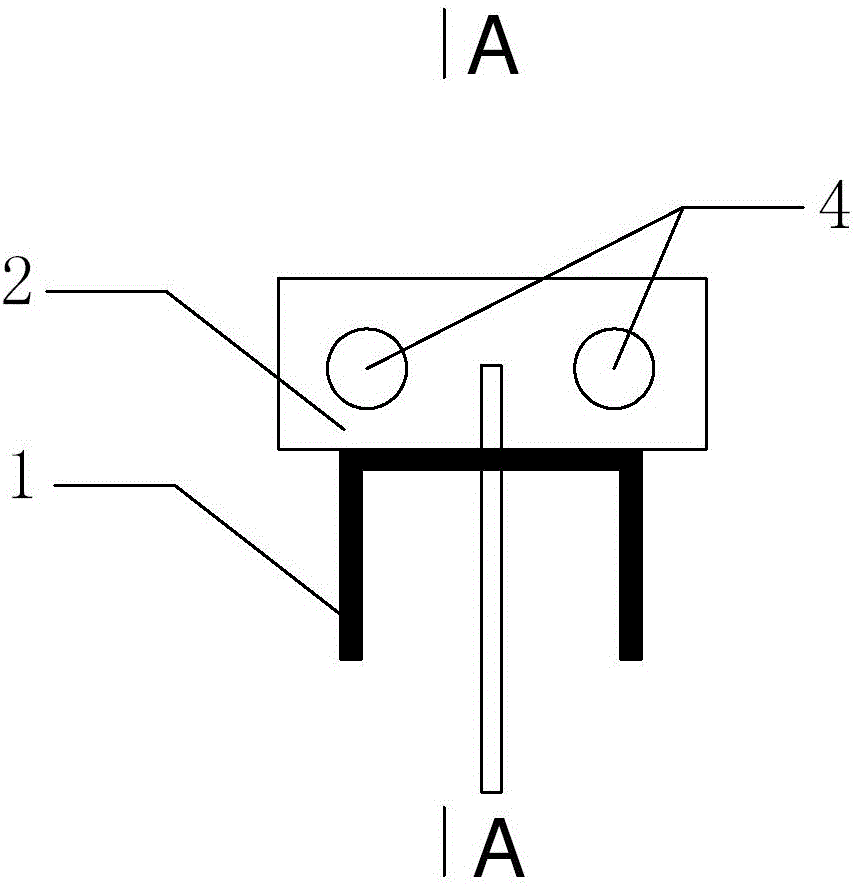

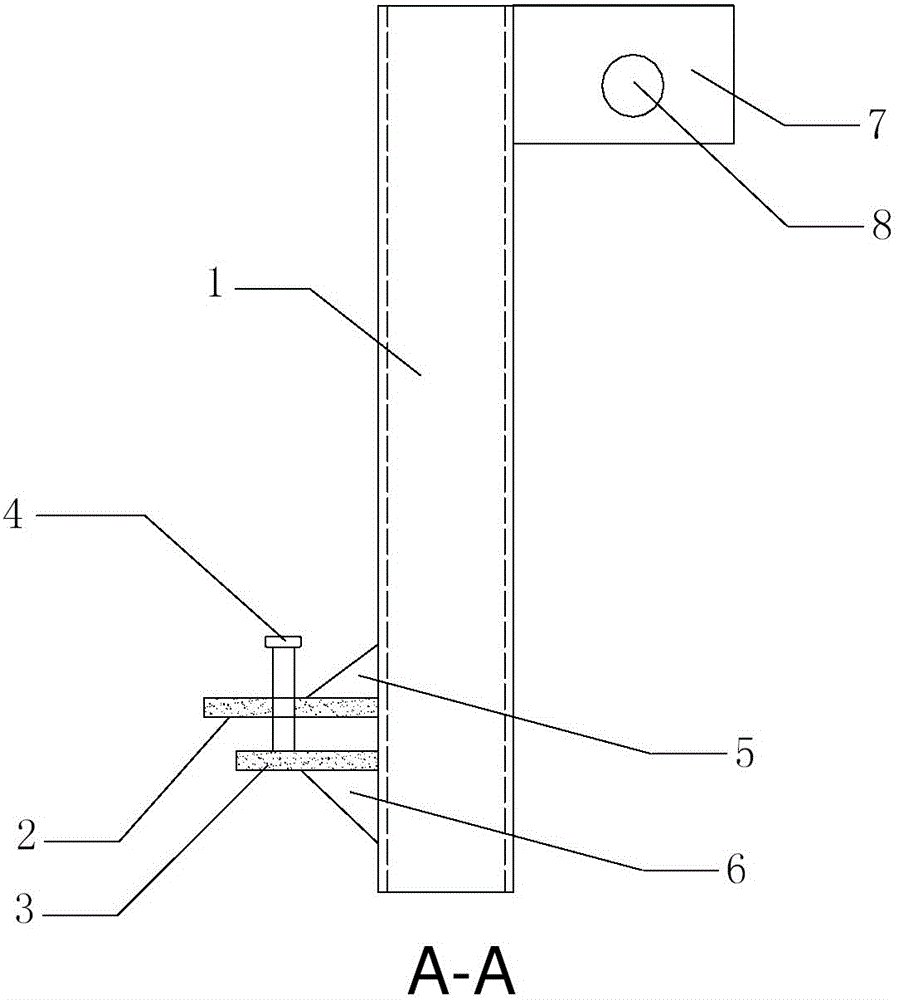

[0033] figure 1 It is a schematic plan view of the structure of the support rod of the embodiment of the present invention, figure 2 for figure 1 A-A sectional view in . As shown in the figure, the support rod is a channel steel 1 with a length of 1.2m as a vertical rod, and two first steel plates 2 and a second steel plate 3 with a thickness of 10 mm at a distance of 3 cm are welded symmetrically up and down at the root of the vertical rod. Two M20 nuts are welded side by side on the first steel plate 2, and matching movable bolts 4 are installed inside the nuts. The first diagonal brace stiffener 5 is arranged on the upper part of the first steel plate, one side of which is welded on the upper part of the first steel plate 2, and the other side Welded with channel steel 1; a second brace stiffener 6 is provided at the lower part of the second steel plate, one side of which is welded at the lower p...

Embodiment 2

[0037] A method for manufacturing a high-altitude safety guardrail for steel structure installation, characterized in that it includes the following steps:

[0038] a. Make the support rod

[0039] Take a channel steel 1 with a length of 1.2m as the pole of the support rod, and weld two pieces of the first steel plate 2 and the second steel plate 3 with a thickness of 10mm and a distance of 3cm at the root of the pole symmetrically up and down. The size of the first steel plate is 15X10mm. 2. The size of the steel plate is 12X10mm, and two M20 nuts are welded side by side on the first steel plate, and the matching movable bolts 4 are installed in the nuts. 1. The upper part of the steel plate 2 is welded with the channel steel 1 on the other side; the second diagonal brace stiffener 6 is arranged at the lower part of the second steel plate, one side is welded at the lower part of the second steel plate, and the other side is welded with the channel steel 1; the first steel pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com