A Micro Free Piston Generator with Air Intake Preheating

A generator and piston technology, applied in the field of micro-power system, can solve the problems of not fully realizing the generator and prime mover, not considering the effective emission of exhaust gas, and low electromagnetic conversion efficiency, so as to increase the exhaust gas cavity and one-way exhaust The effect of valve structure, optimization of exhaust gas discharge capacity, and avoidance of energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

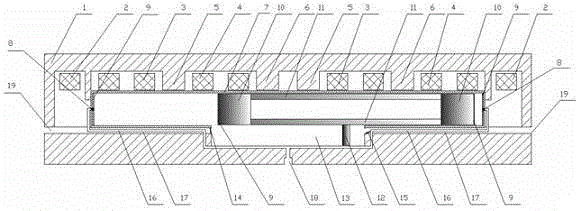

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

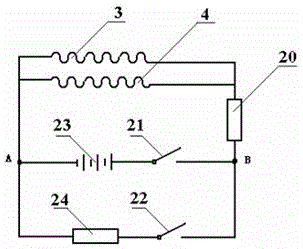

[0028] Such as figure 1 and figure 2 As shown, when in use, the battery switch 21 is first closed, and the current generated in the battery 23 is converted into alternating current through the current inverter 20, and the alternating magnetic field is generated through the left stator winding 3 and the right stator winding 4, and the alternating magnetic field acts The magnetic piston 10 makes it reciprocate, thus completing the starting work of the generator.

[0029] The magnetic piston 10 moves left and right in the alternating magnetic field, and after obtaining a certain speed, the mixed gas injector 8 is opened to start injecting the mixed gas; Figure 4 As shown, when the magnetic piston 10 moves to the right, the left-end mixed gas injector 8 is opened, and the mixed gas is injected into the left-end micro-combustion chamber cylinder 7; as Figure 5 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com