Air inlet flow guide pipe and preparation method thereof

A guide tube and intake hose technology, applied in intake muffler, mechanical equipment, combustion air/combustion-air treatment, etc., can solve the complex direction of intake guide tube, large intake resistance, bellows It can improve the NVH level, improve the noise reduction effect, and improve the assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] Intake guide pipe: In the car air intake system, the air intake pipe connecting the air intake port and the air filter is also called a dirty pipe; it is used to guide air into the air filter.

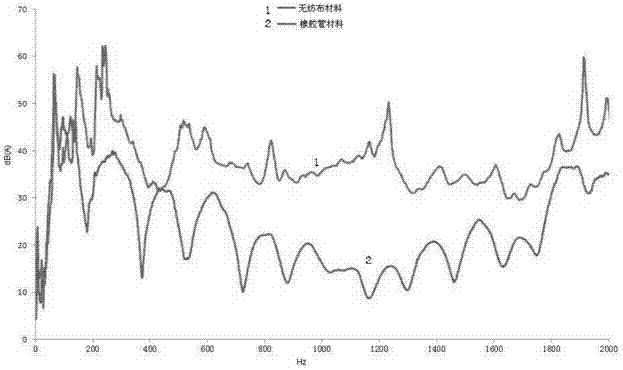

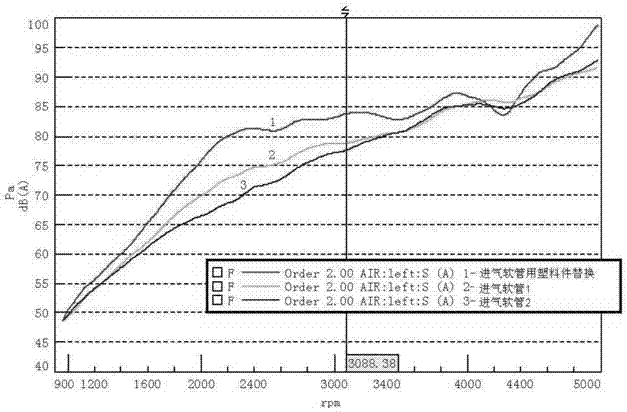

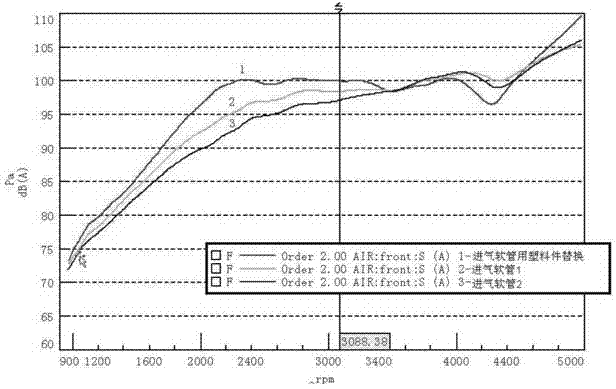

[0036] Such as figure 1 As shown, an air intake duct includes an air inlet 1, a first rigid pipeline 2, an intake hose 3 and a second rigid pipeline 4, and one end of the first rigid pipeline 2 is fixedly connected to the first The air inlet 1 and the other end are fixedly connected to the air intake hose 3, one end of the air intake hose 3 is connected to the first rigid pipeline 2, and the other end is connected to the second rigid pipeline 4; wherein, the air intake soft The tube 3 is a hollow pipeline with a corrugated structure formed by a porous non-woven fabric 31 and a glass filament 32 spirally woun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com