LED COB quartz lamp and manufacture method thereof

A technology of quartz lamps and lamp cups, which is applied in the cooling/heating devices of lighting devices, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., and can solve the problem of color temperature not meeting eye standards, large luminous range angles, and uneven light spots and other problems to achieve the effect of good light concentrating effect, good light color temperature and uniform light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

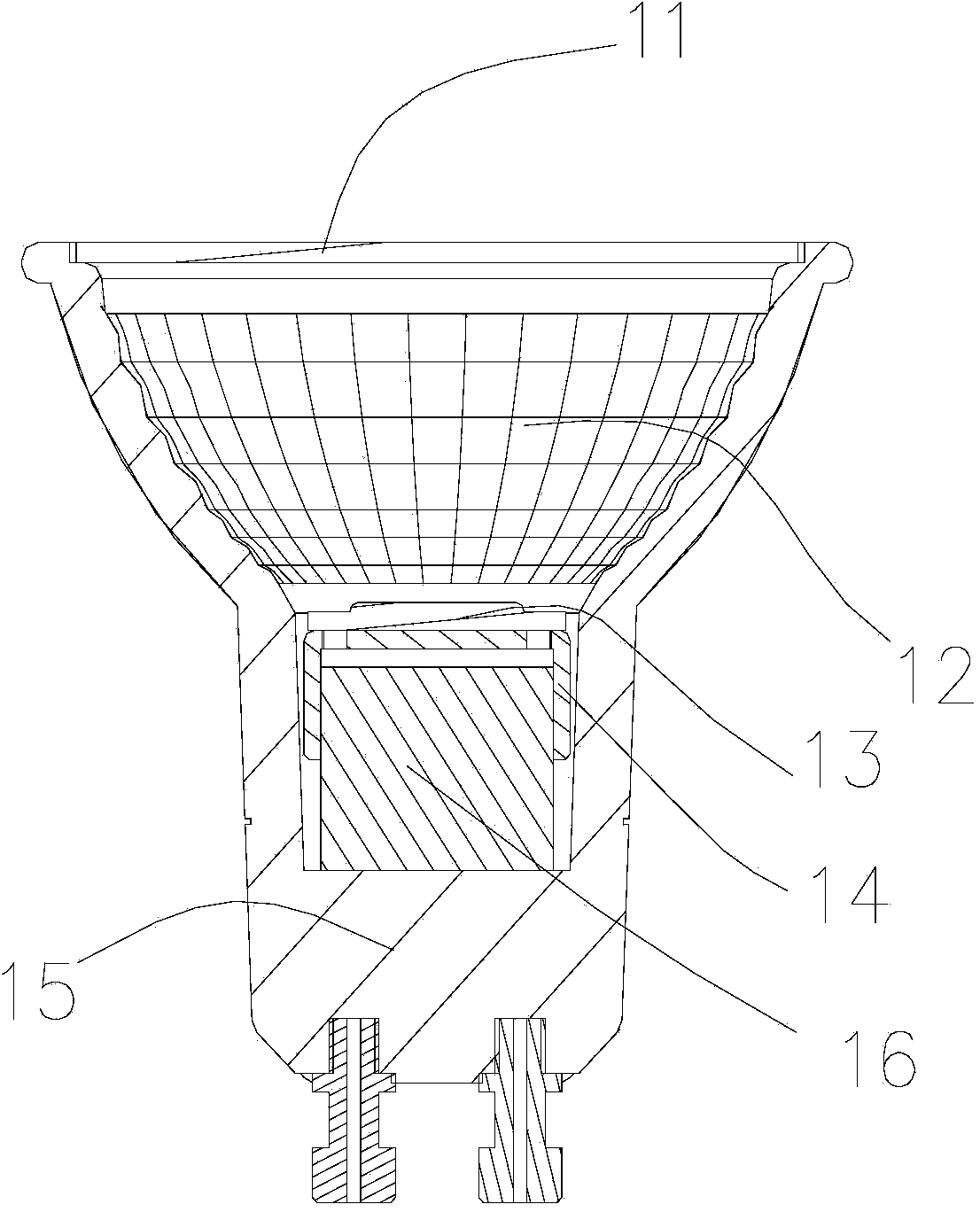

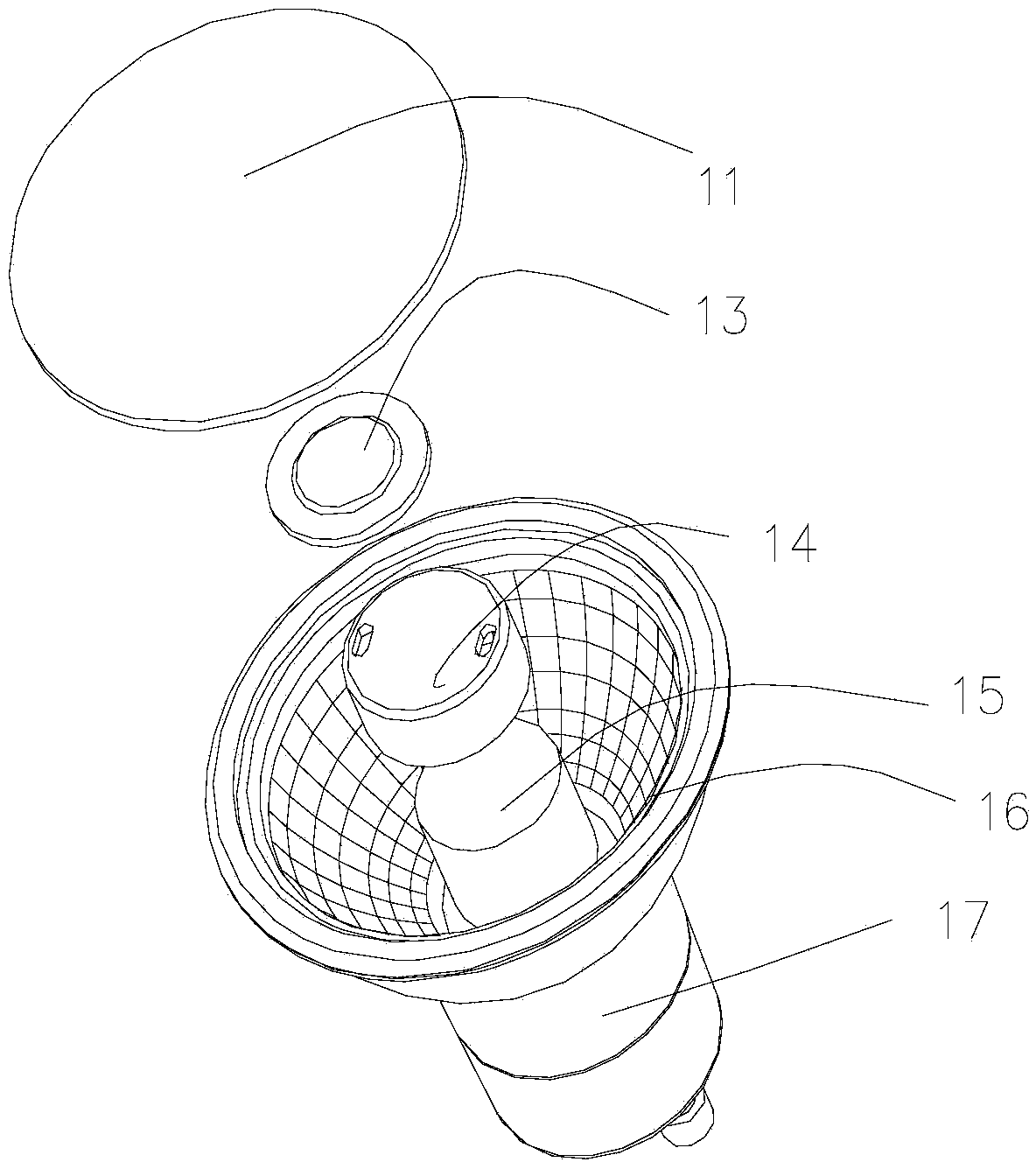

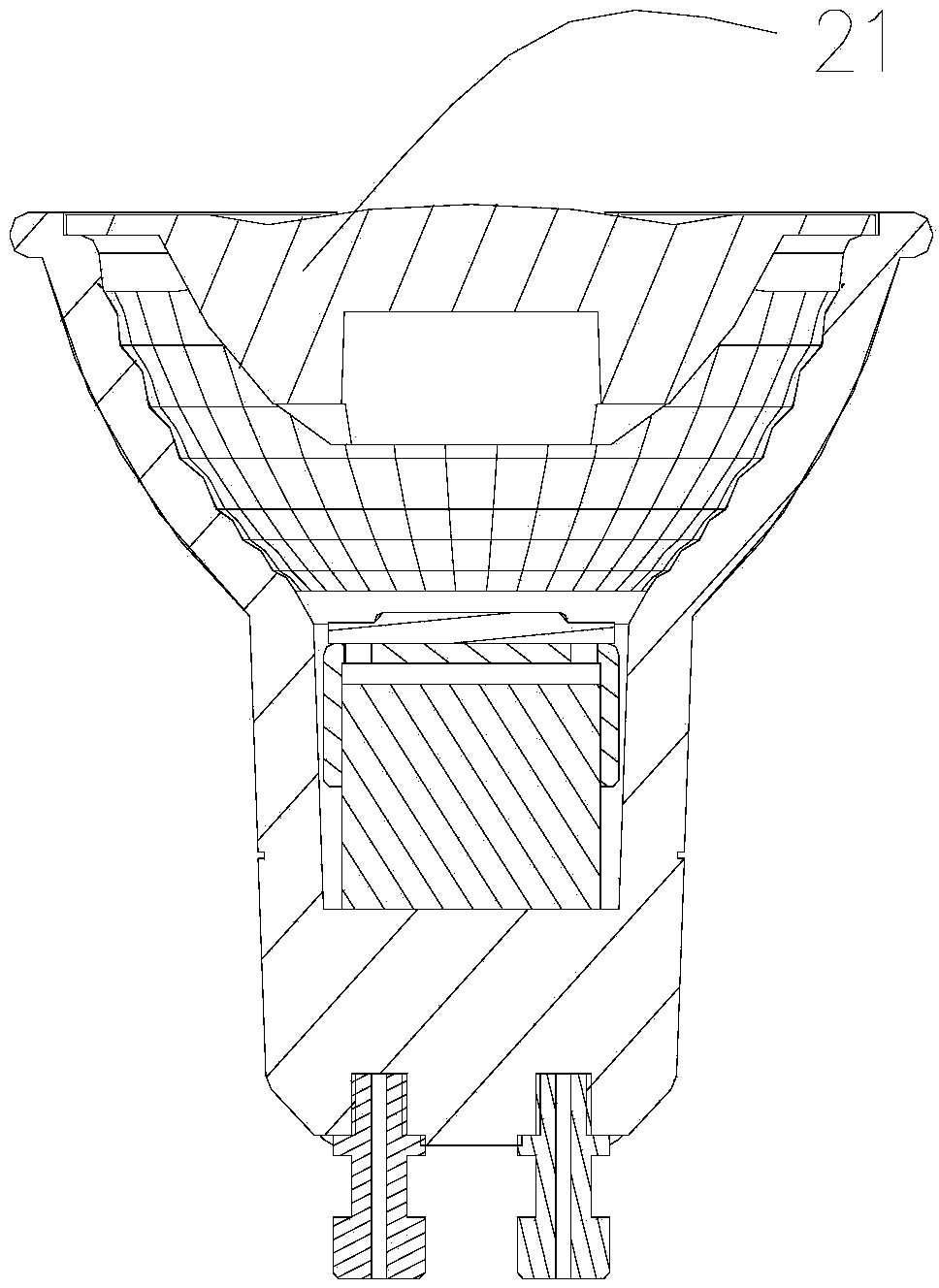

[0047] See figure 1 and figure 2 , The present invention relates to an LED COB quartz lamp, the first preferred embodiment of which includes a transparent glass sheet 11 , a reflective cup 12 , an LED COB chip 13 , a radiator 14 , a power supply assembly 16 and a lamp cup 15 .

[0048] The heat sink 14 has a cavity through the bottom wall, and the upper end of the power supply assembly 16 is accommodated in the cavity to expand the contact area between the power supply assembly 16 and the heat sink 14, so that heat can be transmitted from multiple directions, which is conducive to accelerating heat dissipation. Speed, improve cooling efficiency. The LED COB chip 13 is mounted on the top wall of the radiator 14 . The LED COB chip 13, the radiator 14 and the power supply assembly 16 are all accommodated in the light cup 15, the reflector cup 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com