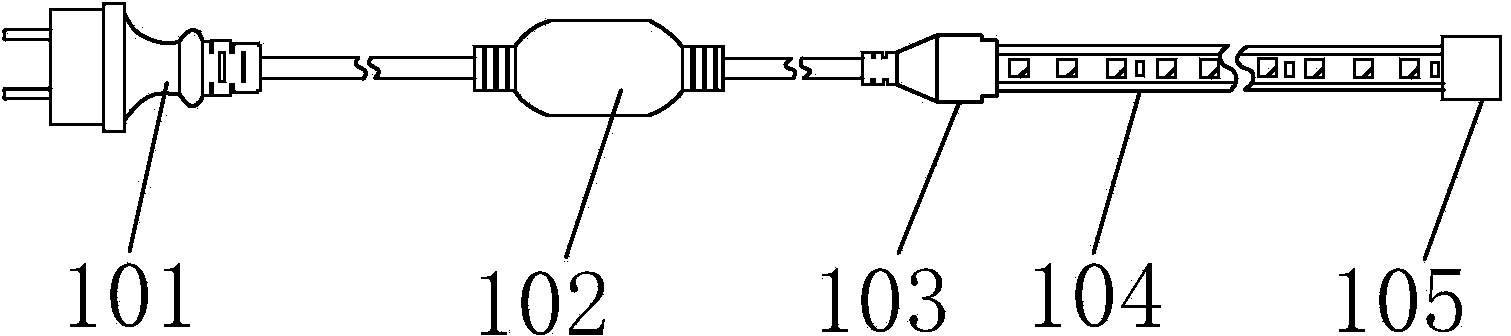

Lamp belt connecting assembly and high-voltage flexible LED lamp belt applying same

A technology for LED light strips and connecting components, which is applied to semiconductor devices of light-emitting elements, components of lighting devices, lighting devices, etc., can solve problems such as safety risks, and achieve reduced use risks, tight assembly structure, and convenient front-to-back connections Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

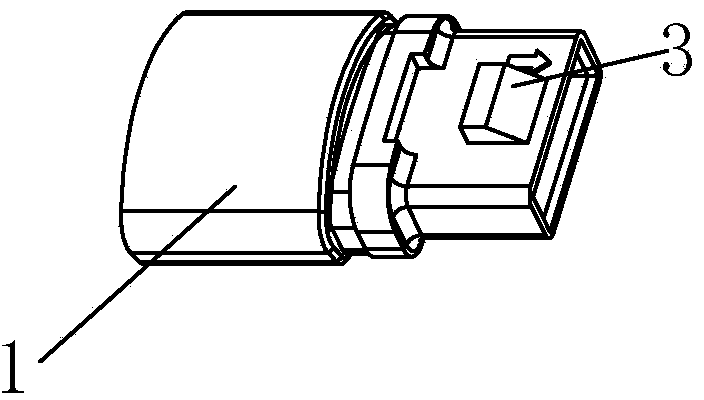

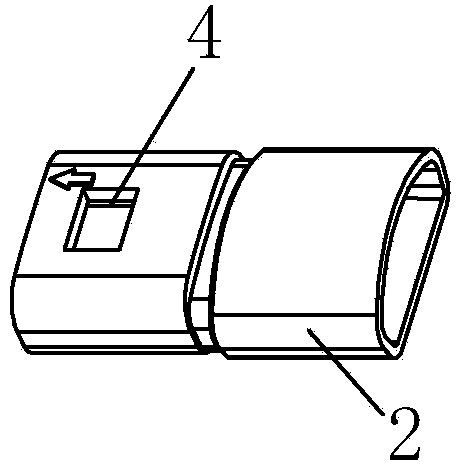

[0021] refer to figure 2 — Figure 5 , a light strip connection assembly of the present invention, including a male plug 1 and a female plug 2, the male plug 1 can be docked with the female plug 2, and the two are closely matched, and the male plug 1 is provided with There is a protrusion 3, and the female plug 2 is provided with a corresponding protrusion hole 4. When in use, only the male plug 1 and the female plug 2 need to be butt-mounted, and fastened with each other through the clamping hole 4 and the protrusion 3, so that the two are fixedly connected. This connection method is convenient, simple, firm and reliable.

[0022] The connection assembly also includes a joint 5 adapted to the male plug 1, the joint 5 can be docked with the male plug 1, and the two are closely matched, and the joint 5 is provided with a protrusion 3 that is compatible with the male plug 1 Corresponding card hole 4. The connector 5 is used to connect the light strip to the power plug, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com