U-shaped vacuum heat pipe type vacuum photo-thermal and photovoltaic conversion glass pipe

A photothermal photoelectric and vacuum heat pipe technology, applied in the field of solar energy utilization, can solve the problem of low solar photothermal conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

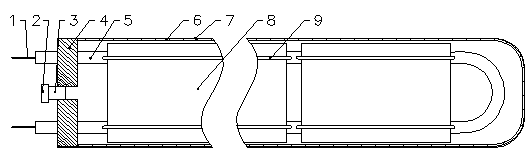

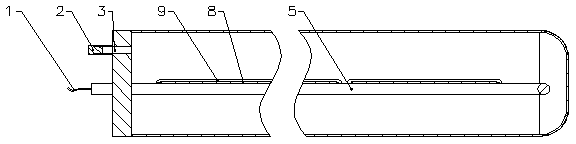

[0019] The present invention will be further explained below in conjunction with the drawings and the description of the drawings.

[0020] The U-shaped vacuum heat pipe type vacuum photothermal photoelectric conversion glass tube is composed of a U-shaped vacuum heat pipe 5, solar cells 8, etc. arranged in the glass tube 6. The two tube ends of the U-shaped vacuum heat pipe 5 are extended outside the glass tube and welded Connect the positive and negative external wires, the 6 port of the glass tube is provided with a welding sealing cover with Kovar 4 as solder, the solar cell 8 and the positive and negative electrodes of the solar cell are fixed on the U-shaped vacuum heat pipe 5 by a fixing band 9 , The welding sealing cover of the 6 port of the glass tube is provided with a vacuum exhaust pipe 3 and a vacuum exhaust pipe plug 2. The U-shaped evacuated heat pipe 5 and the solar cell 8 are placed in the vacuum cavity of the glass tube 6. The solar cell 8 converts sunlight into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com