Rotary fiber Bragg grating large displacement sensor based on gear and application method thereof

A rotary, sensor technology, used in instruments, optical devices, measuring devices, etc., can solve the problem of difficult packaging of measurement deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

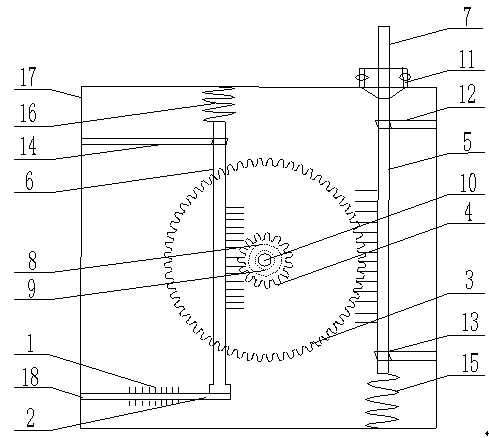

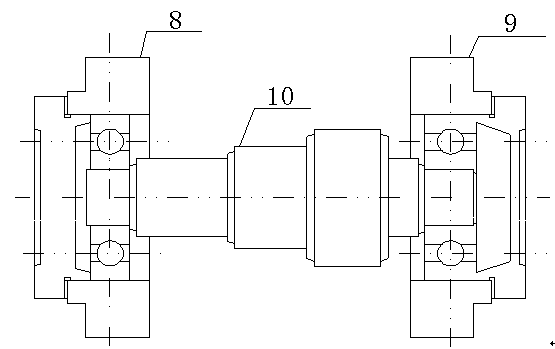

[0059] Implementation mode one: if figure 1 and 2 As shown, the present embodiment is based on the structure of the gear-rotating optical fiber Bragg grating large-displacement sensor: it includes a displacement measurement and transmission device, a displacement size conversion device and a displacement sensing device, and the above-mentioned devices are all fixed inside the metal box 17, and the displacement measurement and transmission The main body of the device is the rack I5 fixed inside the metal box 17 through the rack sleeve I12 and the rack sleeve II13. The upper end of the rack I5 extends out of the metal box 17 and is fixed by the displacement limiting sleeve 11; The structure of the conversion device is that the stepped shaft 10 is coaxially connected with the large gear 3 and the pinion 4; the main body of the displacement sensing device is the rack II 6 which is fitted through the rack bushing III 14 at the upper end and fixedly connected with the cantilever bea...

Embodiment approach 2

[0075] Implementation mode two: if figure 1 and 2 As shown, the present embodiment is based on the structure of the gear-rotating optical fiber Bragg grating large-displacement sensor: it includes a displacement measurement and transmission device, a displacement size conversion device and a displacement sensing device, and the above-mentioned devices are all fixed inside the metal box 17, and the displacement measurement and transmission The main body of the device is the rack I5 fixed inside the metal box 17 through the rack sleeve I12 and the rack sleeve II13. The upper end of the rack I5 extends out of the metal box 17 and is fixed by the displacement limiting sleeve 11; The structure of the conversion device is that the stepped shaft 10 is coaxially connected with the large gear 3 and the pinion 4; the main body of the displacement sensing device is the rack II 6 which is fitted through the rack bushing III 14 at the upper end and fixedly connected with the cantilever bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com