A method for measuring the uniformity of triacetin applied in cigarette filter rods

A technology for triacetin and cigarette filter rods is applied in the field of measuring the uniformity of the amount of triacetin applied in cigarette filter rods, which can solve the problems of inability to measure the uniformity of triacetin and low accuracy, and achieves improved filtering. Rod forming equipment, the effect of improving the technological level and stabilizing the quality of tobacco products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

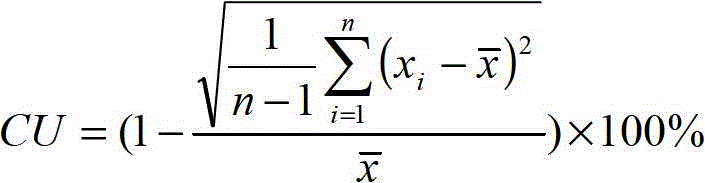

Method used

Image

Examples

Embodiment 1

[0023] (1) Sampling: According to the requirements of the national standard "GB / T19616-2004 General Rules for Sampling of Tobacco Raw Materials in Batches" from a certain machine in the filter rod forming workshop of a company, 30 filter rod samples from the filter rod forming workshop were taken at intervals of 1 min. batches;

[0024] (2) Sample placement: Place the filter rod sample in the regulated atmospheric environment specified in "GB / T16447-2004 Atmospheric Environment for Conditioning and Testing of Tobacco and Tobacco Products" for at least 24 hours;

[0025] (3) Sample cutting: the radial cutting of the filter rod is 1 cm, and the axial cutting of the filter rod is 1 / 8.

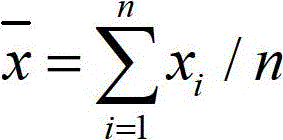

[0026] (4) Detection: the prepared test samples are randomly numbered, and the triacetin content in the test sample is detected according to the tobacco industry standard "YC / T331-2010 Determination of Triacetin in the Fiber Acetate Filter Stick Gas Chromatography". The results are as follows:

...

Embodiment 2

[0032] (1) Sampling: Take 30 samples of filter rods from the filter rod forming workshop at a time interval of 2 minutes in accordance with the requirements of the national standard "GB / T19616-2004 General Rules for Sampling Batch Raw Materials of Tobacco" in a certain machine in the filter rod forming workshop of a certain company batches;

[0033] (2) Sample placement: Place the filter rod sample in the regulated atmospheric environment specified in "GB / T16447-2004 Atmospheric Environment for Conditioning and Testing of Tobacco and Tobacco Products" for at least 24 hours;

[0034] (3) Sample cutting: the radial cutting of the filter rod is 2 cm, and the axial cutting of the filter rod is 1 / 4.

[0035] (4) Detection: the prepared test samples are randomly numbered, and the triacetin content in the test sample is detected according to the tobacco industry standard "YC / T331-2010 Determination of Triacetin in the Fiber Acetate Filter Stick Gas Chromatography". The results are a...

Embodiment 3

[0041] (1) Sampling: According to the national standard "GB / T19616-2004 General Rules for Sampling Batch Raw Materials of Tobacco" from a certain machine in the filter rod forming workshop of a company, 40 filter rod samples from the filter rod forming workshop were taken at intervals of 3 minutes. batches;

[0042] (2) Sample placement: Place the filter rod sample in the regulated atmospheric environment specified in "GB / T16447-2004 Atmospheric Environment for Conditioning and Testing of Tobacco and Tobacco Products" for at least 24 hours;

[0043] (3) Sample cutting: the radial cutting of the filter rod is 4 cm, and the axial cutting of the filter rod is 1 / 2.

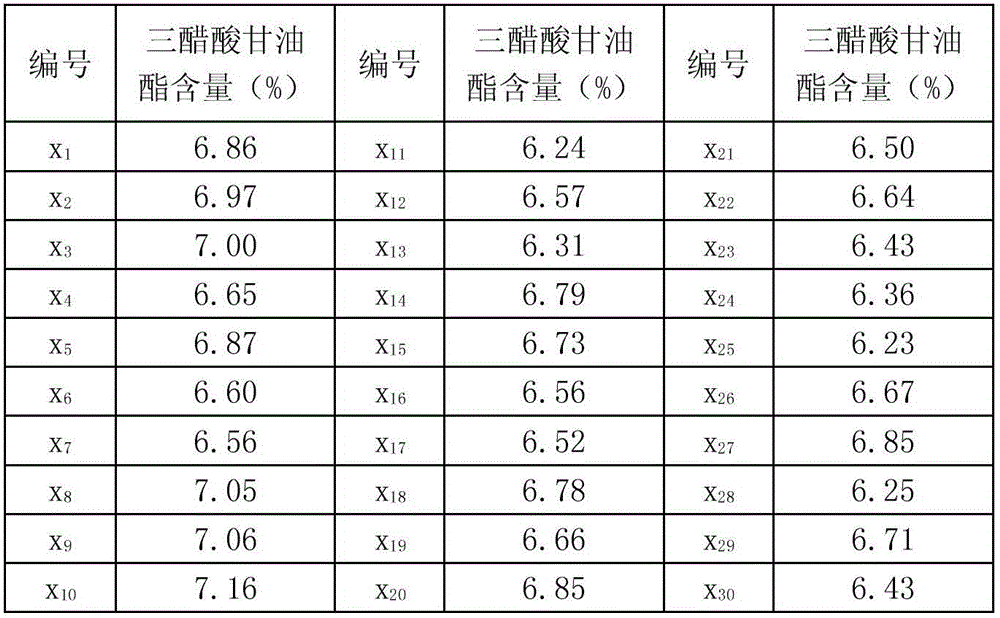

[0044] (4) Detection: the prepared test samples are randomly numbered, and the triacetin content in the test sample is detected according to the tobacco industry standard "YC / T331-2010 Determination of Triacetin in the Fiber Acetate Filter Stick Gas Chromatography". The results are as follows:

[0045]

[0046] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com