Spline structure body with multiple convex keys on inner layer wall of aluminum alloy hollow sleeve and machining method

A technology of aluminum alloy and structural body, which is applied in the direction of couplings, rigid shaft couplings, mechanical equipment, etc., can solve the problems of affecting the coaxiality of parts, low processing efficiency of slotting machines, and poor processing of internal keys, etc., to achieve guaranteed Accuracy, improving the level of mechanical processing technology, and reducing the effect of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

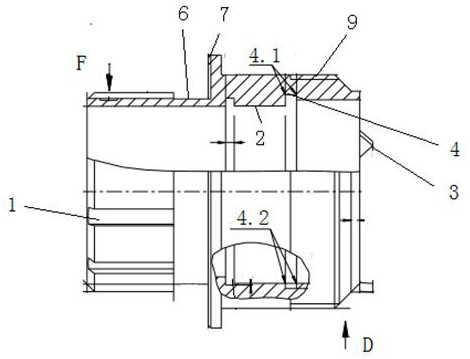

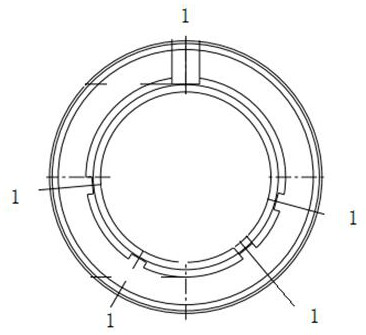

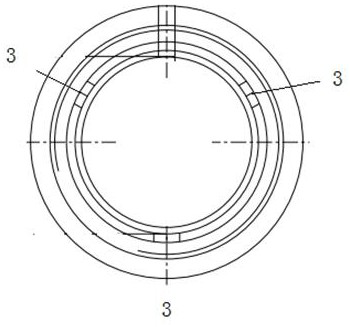

[0043] like figure 1 , 2 , 3, 4, and 5, a spline structure with multiple convex keys on the inner wall of an aluminum alloy hollow sleeve, which is a five-slot spline structure, including: a hollow shell of an aluminum alloy hollow sleeve structural member, the One end of the hollow shell is provided with five splines 1 for spline connection with the interface, and the five splines 1 are located on the surface of the outer ring 5 of the splines; the other end of the hollow shell is provided with a ring platform connection thread for mating connection 9. There is a hollow sleeve circular boss 7 between the five splines 1 and the ring platform connecting thread 9, and a key side ring groove 6 is placed between the hollow sleeve circular boss 7 and the spline outer ring 5, and the ring platform connecting thread 9 Triangular teeth 3 are arranged on the port surfaces;

[0044] The hollow shell is provided with a through hole, wherein the diameter of the through hole from the spl...

Embodiment 2

[0061] like Image 6 , 7 , 8, a spline structure with multiple convex keys on the inner wall of an aluminum alloy hollow sleeve is a five-spline structure, and a hollow sleeve base is placed between the hollow sleeve circular boss 7 and the ring platform connecting thread 9 Ring groove 8; a single key 2 is arranged on the wall of the through hole at the lower part of the hollow sleeve base ring groove 8; a transverse groove 4 is arranged at a position 1 / 3 of the diameter of the large through hole from the port of the ring platform connecting thread 9.

[0062] The five splines 1 are 5 stepped splines, and the cross-sectional distribution of the five splines 1 is as follows: the first spline is arranged on the top of the vertical center line of the spline outer ring 5, and the second spline is arranged on the spline outer ring 5 On one side of the horizontal centerline, the third and fourth splines are arranged below the first spline, and are respectively located on both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com