Flow shop rescheduling method

A rescheduling, workshop technology, applied in electrical program control, comprehensive factory control, etc., can solve problems such as inability to comprehensively consider various emergencies, inability to solve large-scale problems, inability to jump out of local optimum, etc., to improve equipment utilization. , to ensure diversity and stability, high guiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

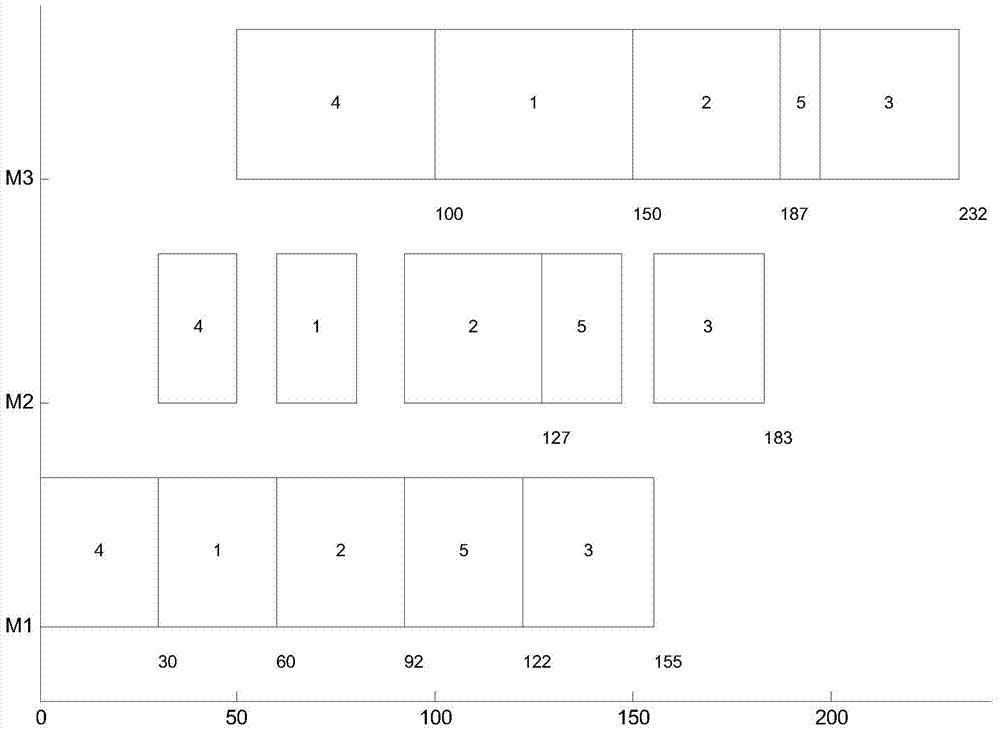

[0042] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0043] This embodiment is to apply the flow workshop rescheduling method to the steelmaking and continuous casting production flow workshop. This workshop produces 5 workpieces and has 3 machine tools. The processing time is shown in Table 1. Among them, the workpiece is J 1 ~ J 5 , the machine tool is M 1 ~ M 3 , the emergency happened at the 10th minute, machine tool M 1 There was a breakdown on , and it took 10 minutes to fix it.

[0044] Table 1 Processing schedule

[0045]

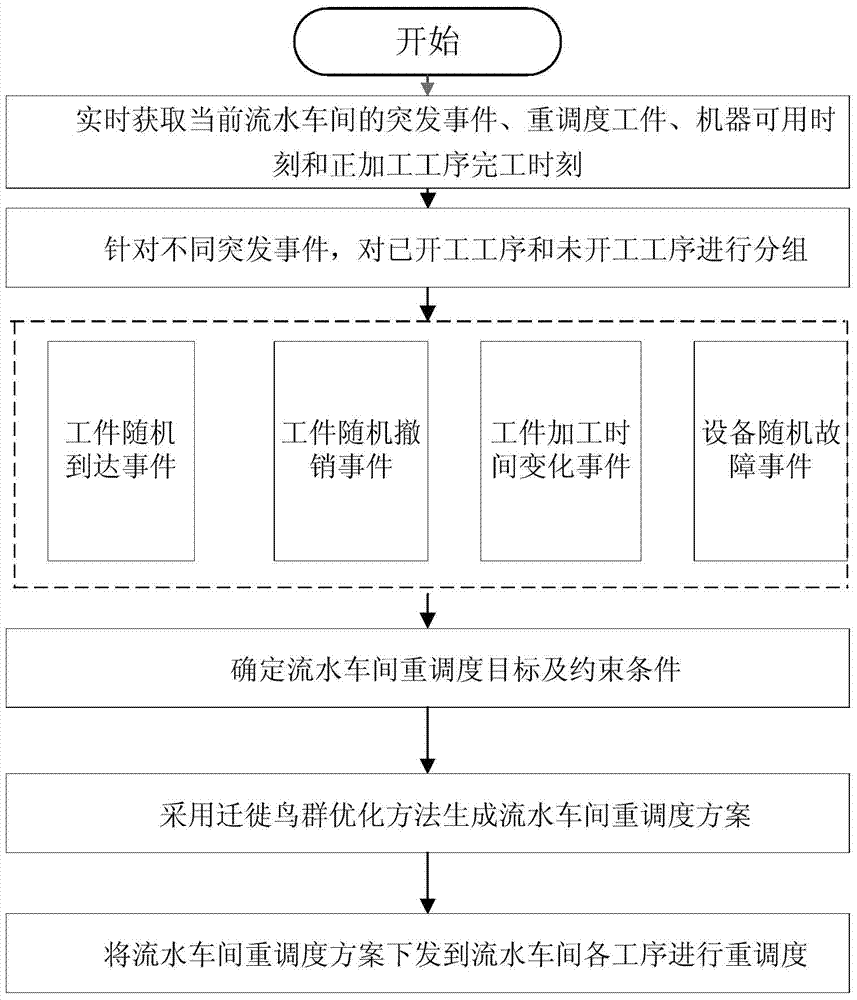

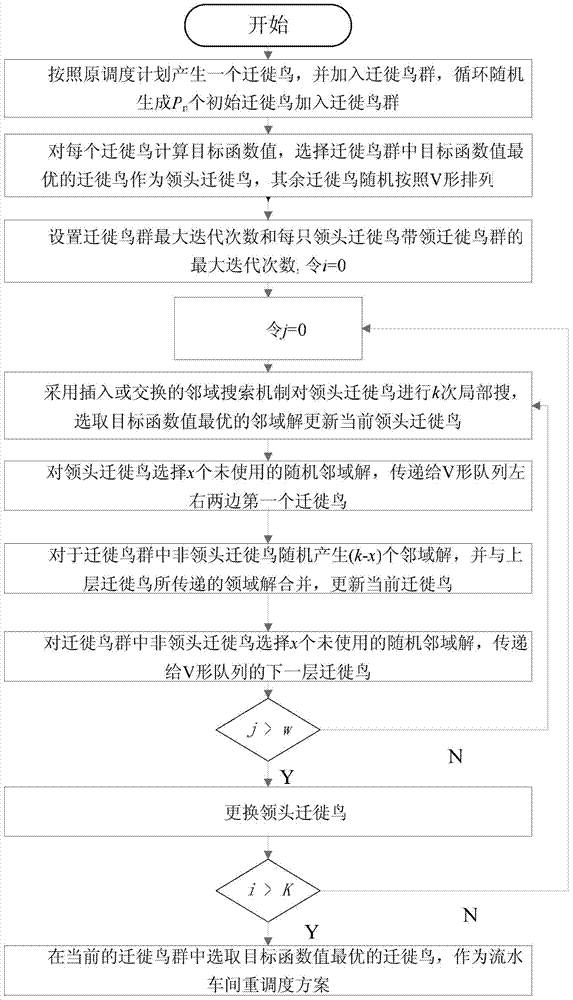

[0046] The flow shop rescheduling method in this embodiment, such as figure 1 shown, including the following steps:

[0047] Step 1: Real-time acquisition of emergencies in the current flow shop, rescheduling workpieces, machine availability time and completion time of the processing process;

[0048] Emergencies include random arrival of workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com