A kind of processing method of LED encapsulation cup body and corresponding mold

A technology of LED packaging and processing methods, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve problems such as affecting the contact and welding between the LED chip and the substrate welding surface, contaminating the welding surface of the chip, affecting the reflection effect, etc., to achieve high quality and consistent. The effect of stability, avoidance of damage, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

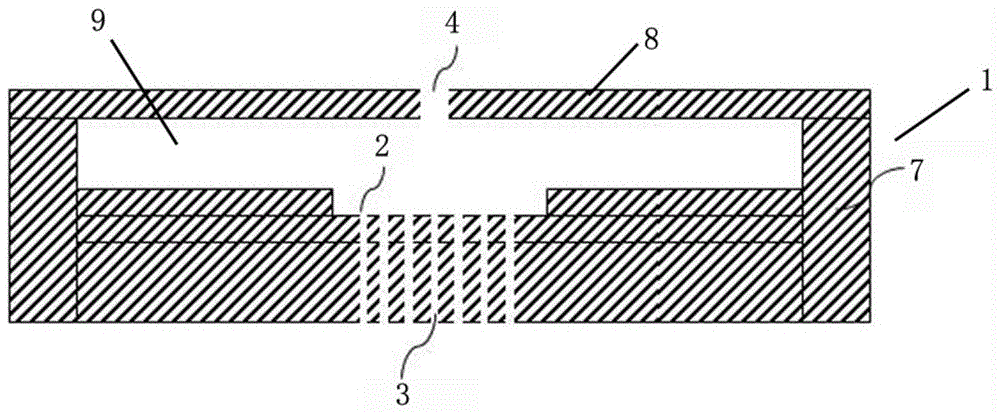

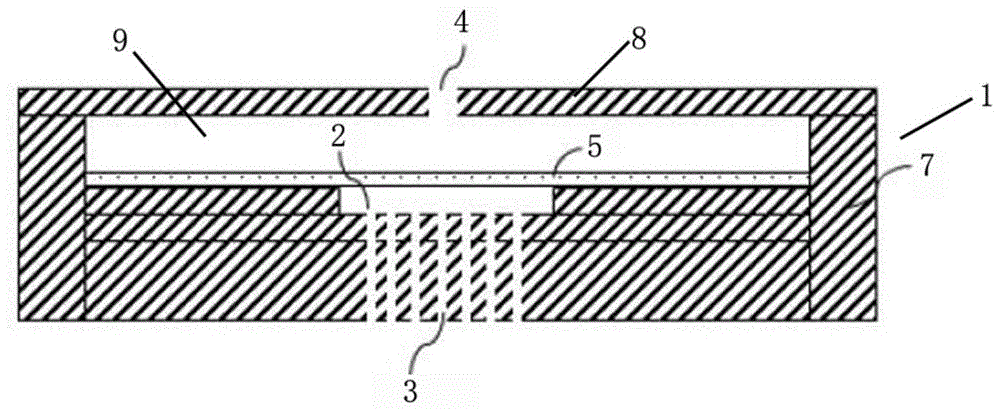

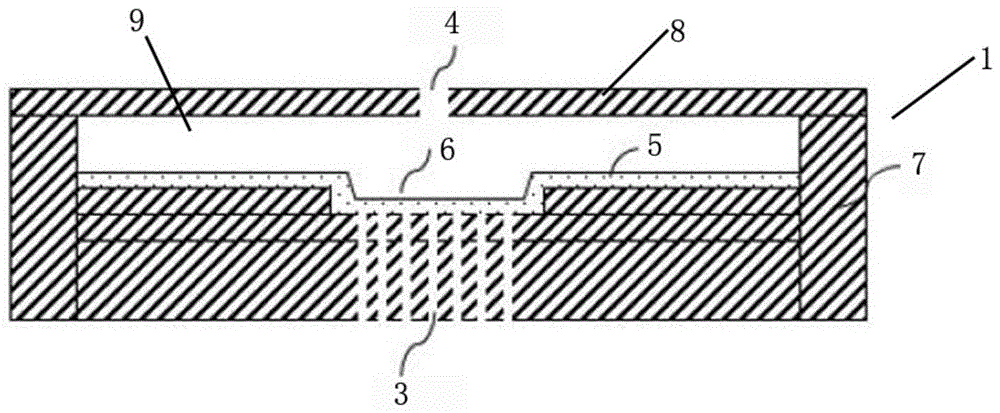

[0028] In a preferred embodiment, the method for processing and forming an LED package cup on a flexible substrate of the present invention includes: first making a figure 1 As shown in the mold 1, the mold 1 includes a base 7 and a cover 8, and the base 7 and the cover 8 are closely matched to form an inner cavity 9, and the bottom surface of the inner cavity 9 is provided with a notch and a concave groove whose bottom shape is circular. Groove 2, a plurality of exhaust through holes 3 are arranged in the position corresponding to the groove 2 in the base 7, and a liquid injection hole 4 is arranged on the cover 8; then a layer is covered on the flexible substrate to protect the reflective layer on the flexible substrate A protective film of material such as polyester film and the flexible substrate 5 covered with the protective film is placed on the bottom surface of the inner chamber 9, such as figure 2 shown in ; then through the liquid injection hole 4 to inject water or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com