Moving contact component of power battery pack of full electric vehicle

A technology of power battery and contact assembly, which is applied in the field of electric vehicles, can solve problems such as instantaneous separation, easy arcing, poor contact, and influence on power transmission efficiency, so as to improve efficiency and reliability, improve efficiency and reliability, and increase conductive area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

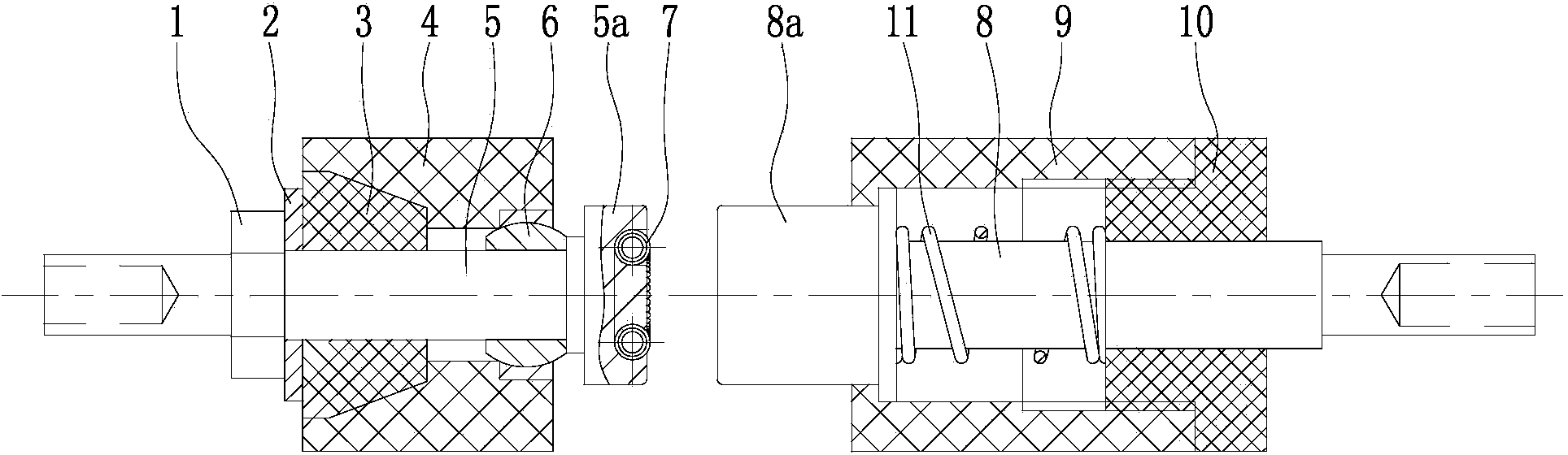

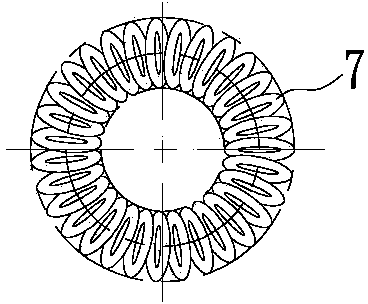

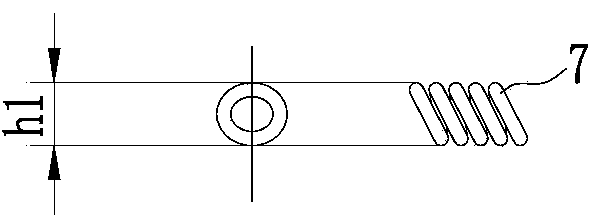

[0019] Such as figure 1 As shown, the present invention consists of a sealing head 3, a moving head seat 4, a moving contact 5, a joint bearing 6 and an elastic conductive ring 7. Wherein, the movable contact 5 is a columnar structure, and is preferably made of silver-copper alloy. The movable contact 5 passes through the central hole of the movable head seat 4, and the front and rear ends of the movable contact 5 are all outside the movable head seat 4, and the movable head seat 4 is made of insulating material. A sealing head 3 is arranged between the rear end of the moving head seat 4 and the moving contact 5. The sealing head 3 is a tapered rubber body with a small front and a large rear. The sealing head 3 is completely embedded in the moving head seat 4. The rear end surface of 3 is basically flush with the rear end surface of the moving head seat 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com