AB3-type hydrogen-storing alloy of nickel-metal hydride battery and preparation method thereof

A technology for hydrogen storage alloys and nickel-metal hydride batteries, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of general performance, high alloy price, poor electrochemical cycle stability, etc., and achieve wide working temperature range and high discharge platform , Excellent cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

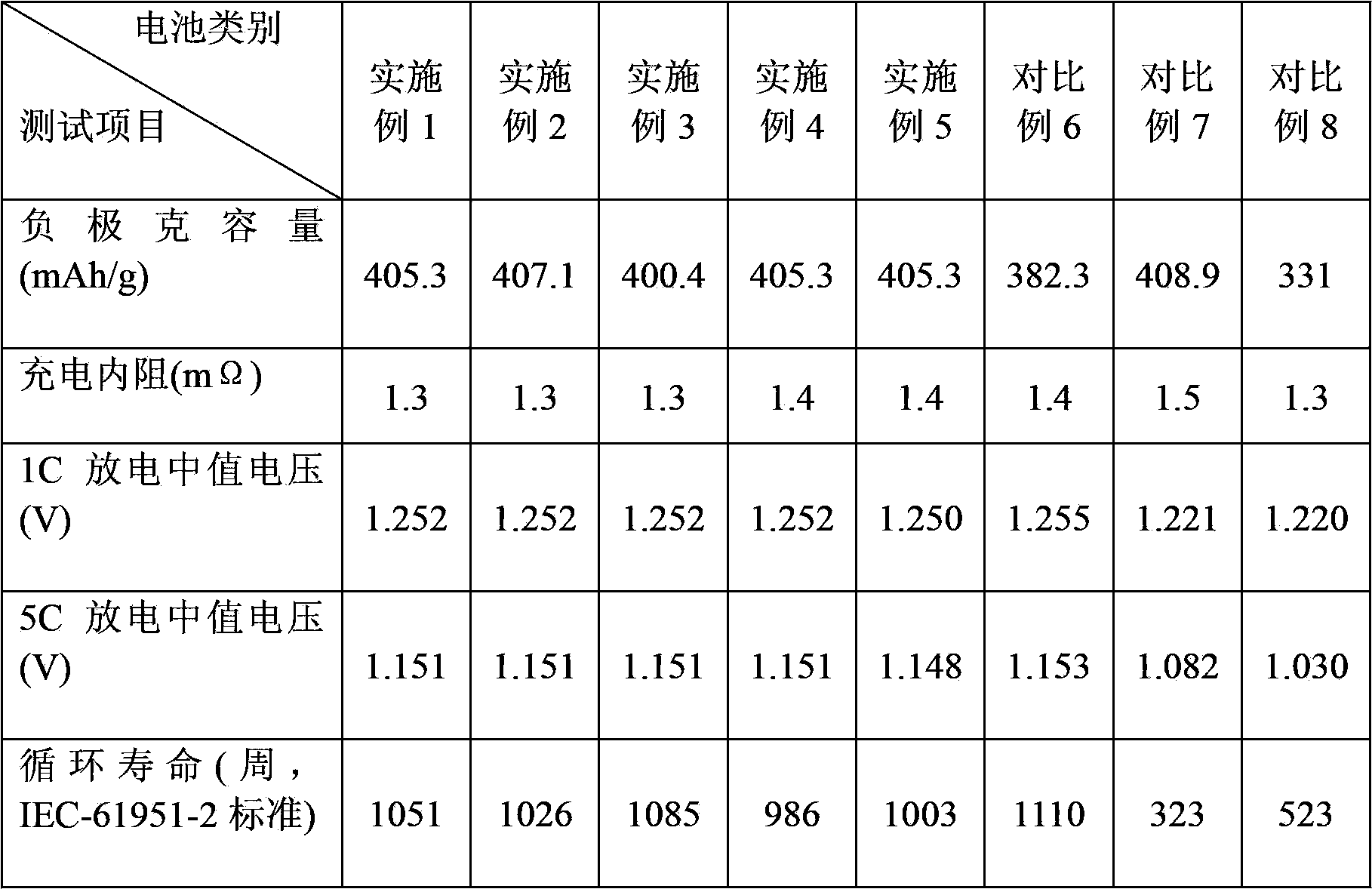

Examples

Embodiment 1

[0012] Making the Invention AB 3 Alloy 20Kg, its stoichiometric formula is MmNi 2.86 sn 0.03 Zr 0.02 Si 0.06 B 0.03 mn 0.21 1Al 0.16 , The weight percent content of side A elements is La25%, Ce 4%, Mg 3.5%. First, weigh La, Ce, Sn, Zr, Si, B, Mn, Al, part of Ni and MgNi alloys in proportion, and use a vacuum high-frequency induction furnace for the first feeding: La, Ce, Sn, Zr, Si , B, Mn, Al and part of Ni, after the feeding is completed, adjust the heating power to 100KW, and then increase the power to 20KW per minute. When the temperature reaches 1410°C, stop heating and stay at this temperature for 30min. The second feeding: add MgNi alloy, after the feeding is completed, stay for 6min. Start casting. After casting, cool the alloy ingot by circulating water, and then anneal. The annealing temperature is 910°C, and the annealing time is 8 hours. 3 Alloy 20Kg.

[0013] Use the obtained alloy to make 50 90M18Ah batteries.

Embodiment 2

[0015] Making the Invention AB 3 Alloy 20Kg, its stoichiometric formula is MmNi 2.86 sn 0.03 Zr 0.02 Si 0.06 B 0.03 mn 0.21 1Al 0.16 , The weight percent content of side A elements is La26%, Ce 3%, Mg 3.5%. First, weigh La, Ce, Sn, Zr, Si, B, Mn, Al, part of Ni and MgNi alloys in proportion, and use a vacuum high-frequency induction furnace for the first feeding: La, Ce, Sn, Zr, Si , B, Mn, Al and part of Ni, after the feeding is completed, adjust the heating power to 100KW, and then increase the power to 20KW per minute. When the temperature reaches 1410°C, stop heating and stay at this temperature for 30min. The second feeding: add MgNi alloy, after the feeding is completed, stay for 6min. Start casting. After casting, cool the alloy ingot by circulating water, and then anneal. The annealing temperature is 910°C, and the annealing time is 8 hours. 3 Alloy 20Kg.

[0016] Use the obtained alloy to make 50 90M18Ah batteries.

Embodiment 3

[0018] Making the Invention AB 3 Alloy 20Kg, its stoichiometric formula is MmNi 2.86 sn 0.03 Zr 0.02 Si 0.06 B 0.03 mn 0.21 1Al 0.16 , The weight percent content of side A elements is La24%, Ce 5%, Mg 3.5%. First, weigh La, Ce, Sn, Zr, Si, B, Mn, Al, part of Ni and MgNi alloys in proportion, and use a vacuum high-frequency induction furnace for the first feeding: La, Ce, Sn, Zr, Si , B, Mn, Al and part of Ni, after the feeding is completed, adjust the heating power to 100KW, and then increase the power to 20KW per minute. When the temperature reaches 1410°C, stop heating and stay at this temperature for 30min. The second feeding: add MgNi alloy, after the feeding is completed, stay for 6min. Start casting. After casting, cool the alloy ingot by circulating water, and then anneal. The annealing temperature is 910°C, and the annealing time is 8 hours. 3 Alloy 20Kg. Use the obtained alloy to make 50 90M18Ah batteries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com