Flavor mushroom sauce and manufacturing process thereof

A manufacturing process and technology of shiitake sauce, applied in food preparation, application, food science and other directions, can solve problems such as unbalanced nutrition, achieve the effect of fragrant and delicious taste, solve unbalanced nutritional matching, and enrich varieties and flavors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

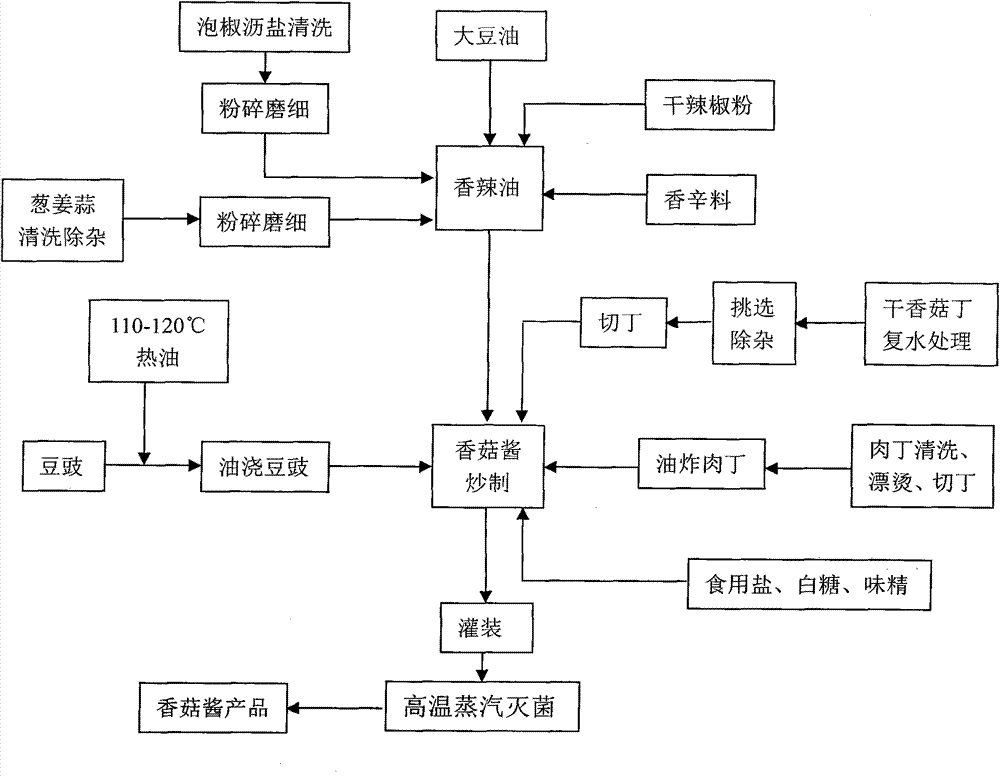

Image

Examples

Embodiment 1

[0019] The raw material formula of this example: 45 parts of diced mushrooms, 25 parts of soybean oil, 15 parts of tempeh, 2 parts of fresh onion, 2.5 parts of fresh ginger, 1.5 parts of fresh garlic, 2.5 parts of edible salt, 2 parts of monosodium glutamate, 2.5 parts of white sugar, 2 parts of spices share.

[0020] Preparation method: (1) Preparation of dried shiitake mushrooms rehydrated and diced: wash the dried shiitake mushrooms until the washing water is light yellow, soak for 1 hour, then spin dry to obtain the rehydrated shiitake mushrooms, manually select, and the selected shiitake mushrooms Diced into 0.5-0.7cm 2 Dried shiitake mushrooms are rehydrated and diced for later use. (2) Preparation of fermented soya bean oil: heating soybean oil to 110-120° C., and pouring fermented soya bean on it to obtain fermented soya bean oil. (4) Preparation of aromatic hot oil: heat soybean oil to 125-135° C., add spices, onion, ginger and garlic ingredients in sequence accordi...

Embodiment 2

[0022] The raw material formula of this example: 35 parts of diced mushrooms, 25 parts of soybean oil, 15 parts of diced pork, 10 parts of tempeh, 1.5 parts of fresh green onion, 2 parts of fresh ginger, 1.5 parts of fresh garlic, 1 part of dried red pepper, and 1 part of pickled pepper , 2.5 parts of edible salt, 2 parts of monosodium glutamate, 1.5 parts of white sugar, and 2 parts of spices.

[0023] Preparation method: (1) Preparation of dried shiitake mushrooms rehydrated and diced: wash the dried shiitake mushrooms until the washing water is light yellow, soak for 1 hour, then spin dry to obtain the rehydrated shiitake mushrooms, manually select, and the selected shiitake mushrooms Diced into 0.5-0.7cm 2 Dried shiitake mushrooms are rehydrated and diced for later use. (2) Preparation of fried diced pork: select fat and lean pork pieces, wash, blanch, rinse and put them into dicing machine to cut them into 0.5-0.7cm 2 of diced meat. Heat the soybean oil to above 110-12...

Embodiment 3

[0025] The raw material formula of this example: 35 parts of diced mushrooms, 25 parts of soybean oil, 12.5 parts of diced beef, 12.5 parts of tempeh, 1.5 parts of fresh green onion, 2 parts of fresh ginger, 1 part of fresh garlic, 2 parts of dried red pepper, and 2 parts of pickled pepper , 2 parts of edible salt, 1 part of monosodium glutamate, 2 parts of white sugar, and 1.5 parts of spices.

[0026] Preparation method: (1) Preparation of dried shiitake mushrooms rehydrated and diced: wash the dried shiitake mushrooms until the washing water is light yellow, soak for 1 hour, then spin dry to obtain the rehydrated shiitake mushrooms, manually select, and the selected shiitake mushrooms Diced into 0.5-0.7cm 2 Dried shiitake mushrooms are rehydrated and diced for later use. (2) Preparation of fried diced beef: select fat and thin beef pieces, wash, blanch, rinse and put into dicing machine to cut into 0.5-0.7cm 2 of diced meat. Heat the soybean oil to above 110-120°C, add t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com