Multi-layer foam dressing for negative pressure closed drainage and preparation method thereof

A production method and negative pressure drainage technology, applied in dressings, viscous dressings, suction devices, etc., can solve the problems of high labor intensity of medical staff, short dressing change cycle of PU dressings, poor negative pressure conduction performance, etc., and improve negative pressure. The effect of conduction efficiency, promoting wound healing and improving negative pressure conduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] composite foam dressing

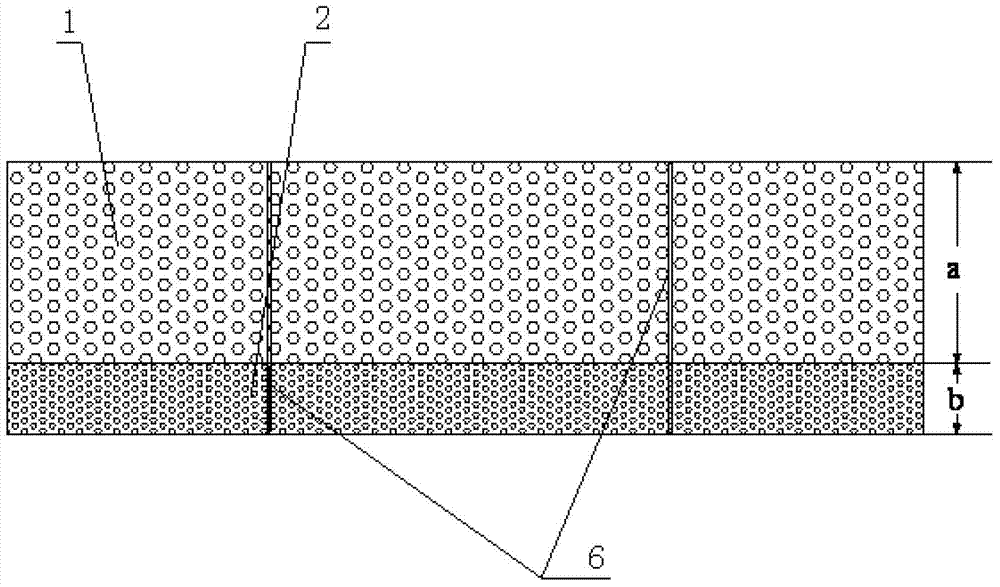

[0106] The dressing has a double-layer structure, which is compounded by a negative pressure conducting layer 1 and a drainage protection layer 2 . The negative pressure conducting layer 1 is made of hydrophobic foam material, and the drainage protection layer 2 is made of hydrophilic foam material.

[0107] The negative pressure conduction layer 1 has a thickness of 1 cm, and the drain protection layer 2 has a thickness of 0.5 cm. The pore diameter of the negative pressure conducting layer 1 is 2.5mm, and the pore diameter of the drainage protective layer 2 is 0.5mm.

[0108] The outer surface of the porous foam material layer on the side away from the wound surface is fixedly connected with an outer surface layer 3b of a sealant film.

Embodiment 2

[0110] composite foam dressing

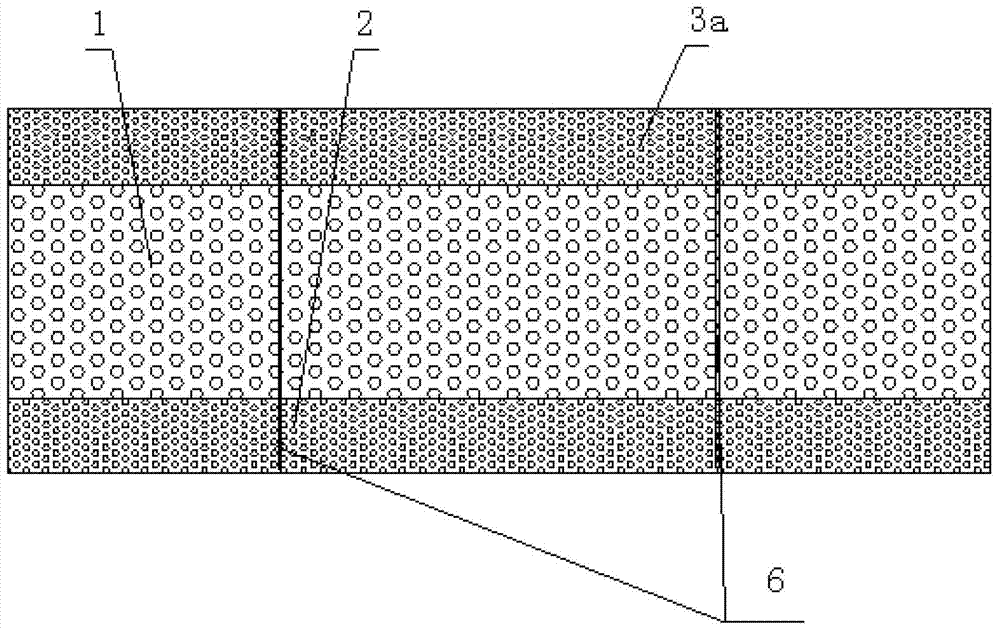

[0111] The dressing has a three-layer structure, and the negative pressure conducting layer 1 is centered. The negative pressure conducting layer 1 is made of hydrophobic foam material, and the drainage protection layer 2 is made of hydrophilic foam material.

[0112] The negative pressure conduction layer 1 has a thickness of 1 cm, and the drain protection layer 2 has a thickness of 0.5 cm. The pore diameter of the negative pressure conducting layer 1 is 2.5mm, and the pore diameter of the drainage protective layer 2 is 0.5mm. The outer surface layer 3a of porous foam is added with a size of 0.5 cm and a pore diameter of 0.5 mm.

Embodiment 3

[0114] Adhesive Foam Dressing

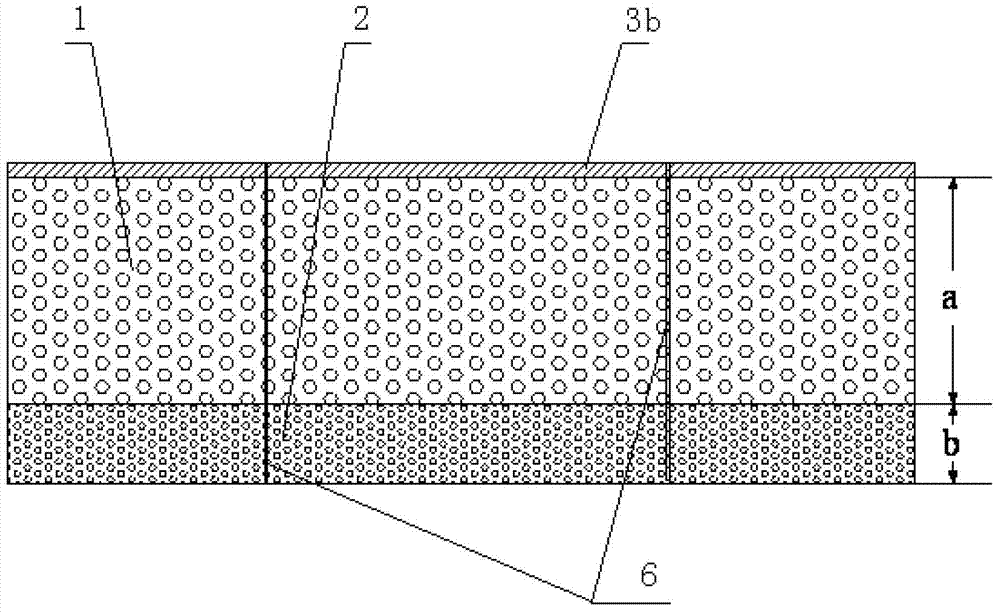

[0115] The dressing has a double-layer structure, and is formed by bonding one layer of negative pressure conduction layer 1 and one layer of drainage protection layer 2 . The negative pressure conducting layer 1 is made of hydrophobic foam material, and the drainage protection layer 2 is made of hydrophilic foam material.

[0116] The negative pressure conduction layer 1 has a thickness of 1 cm, and the drain protection layer 2 has a thickness of 0.5 cm. The pore diameter of the negative pressure conducting layer 1 is 2.5mm, and the pore diameter of the drainage protection layer 2 is 0.5mm.

[0117] The bonding method is multi-point glue bonding. The outer surface of the porous foam material layer on the side away from the wound surface is fixedly connected with an outer surface layer 3b of a sealant film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com