Environmental-protection dust remover of boiler

A technology for dust collectors and boilers, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of affecting the operation effect and efficiency of boilers, easy to block dust removal guide plates, low dust removal efficiency, etc., to improve the mixing effect. , reduce water content, improve the effect of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

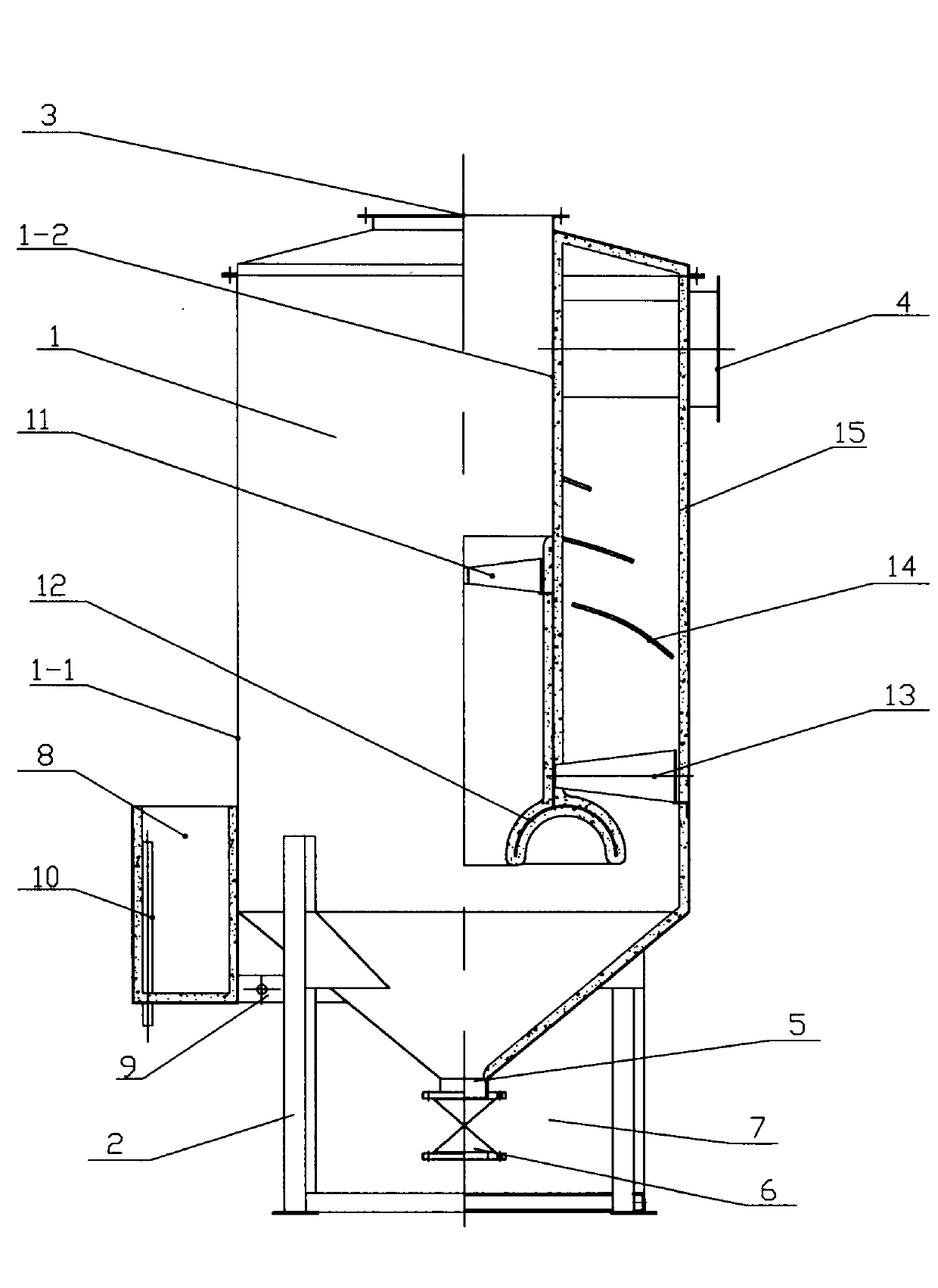

[0008] detailed description Next, the present invention will be described in detail in conjunction with the accompanying drawings

[0009] Such as figure 1 As shown, the bottom of the dust removal chamber 1 is supported by the base frame 2 welded thereto. The dust removal chamber is composed of two hollow shells, that is, an outer shell 1-1 and an inner shell 1-2. The inner shells are both open, the upper end wall of the inner shell is welded with the inner top wall of the outer shell, the top of the outer shell is provided with a smoke inlet pipe 3 communicating with the inner shell, and the side of the outer shell is provided with a smoke outlet pipe communicating with the inside 4. The lower part of the shell is provided with an ash discharge port 5, and a valve 6 is provided at the ash discharge port; the bottom of the shell is provided with an ash cleaning tank 7 corresponding to the ash discharge port, and the ash cleaning tank is a groove-shaped shell with an upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com