A jet self-priming foaming agent parallel foaming system

A foaming system and foaming agent technology, applied in the field of engineering, can solve the problems of increasing the explosion of electrical appliances, insufficient pressure, blockage of the throat, etc., and achieve the effects of increasing the foaming ratio, enhancing the driving ability and reducing the pressure loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

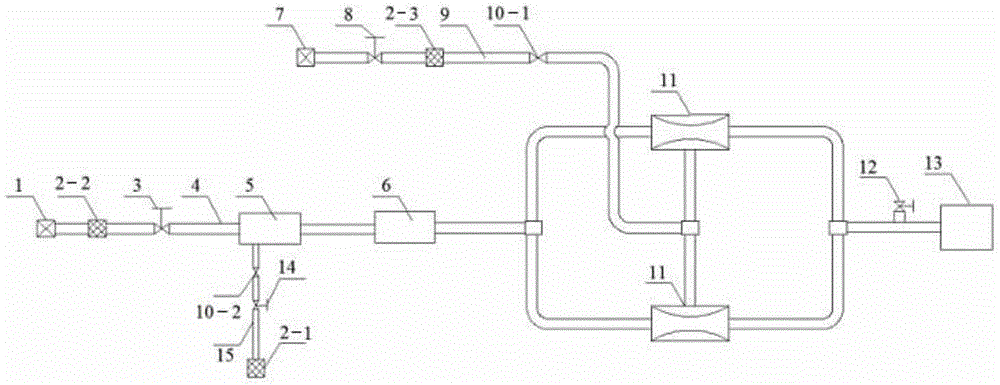

[0023] The present invention will be further described below in conjunction with accompanying drawing.

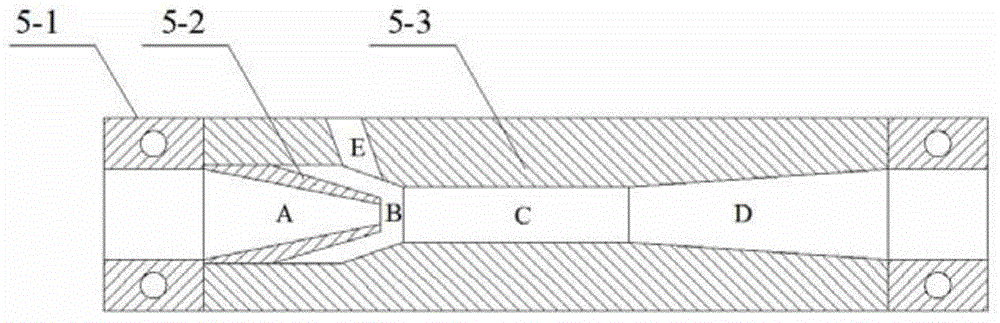

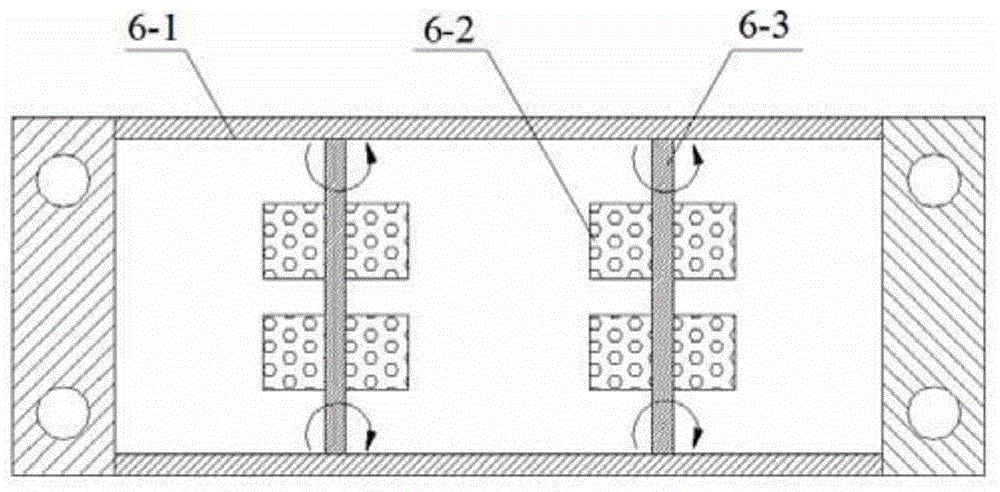

[0024] like figure 1 As shown, a kind of jet self-priming foaming agent parallel foaming system of the present invention comprises a proportional mixer 5, a foam generator 11, a water inlet joint 1, an air inlet joint 7, a pressure air pipe 9, a foam distributor 13 and The liquid suction pipe 15 connected with the proportional mixer 5, the water inlet joint 1 is connected with the proportional mixer 5 through the high pressure water pipe 4, the air inlet joint 7 is connected with one end of the air pressure pipe 9, and the high pressure water pipe 4 and the air pressure pipe 9 There are filter B2-2 and filter C2-3 respectively; the number of the foam generators 11 is not less than two, and they are connected in parallel; the inlet of the parallel foam generators 11 and the proportional mixer 5, the outlet of the parallel foam generator 11 is provided with a foam observatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com