Integrated high-speed punch bed

A high-speed punch, integrated technology, applied in the direction of press, engine components, engine lubrication, etc., can solve the problems of complex structure, poor oil return, easy eccentricity of the crankshaft, etc., to achieve good overall rigidity and smooth oil return.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

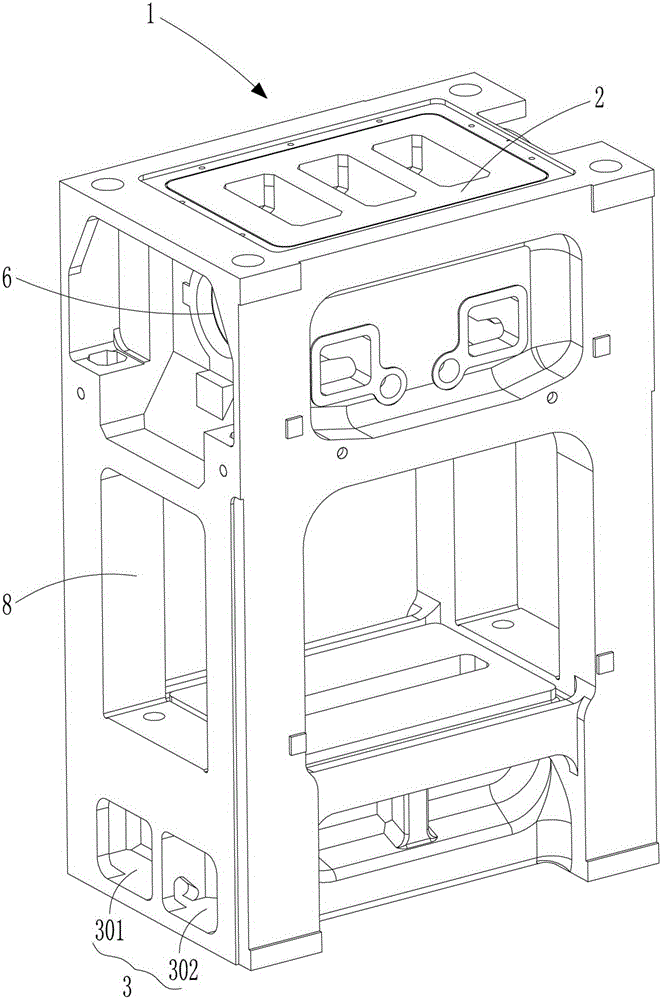

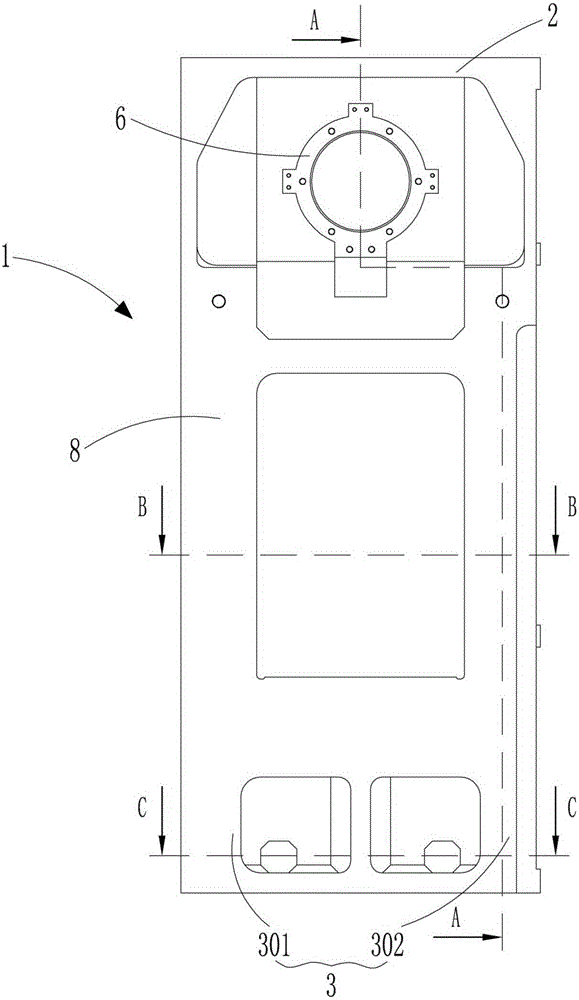

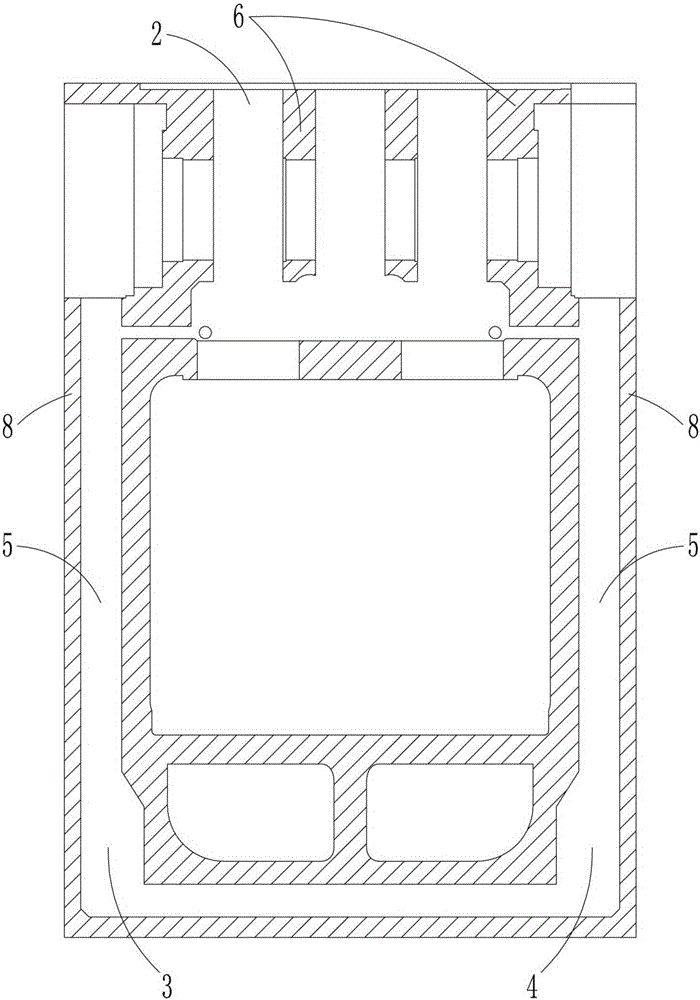

[0020] as attached figure 1 to attach Figure 5 As shown, a one-piece high-speed punch bed, the whole bed is integrally cast, including a main body 1, a crankcase 2 arranged on the main body 1, a main oil tank 3 and an auxiliary oil tank 4 arranged on the main body 1, the main body There are four uprights 8 on 1, and the inner cavity of the uprights 8 forms an oil return pipeline 5 connected between the main oil tank 3 and the crankcase 2, and between the auxiliary oil tank 4 and the crankcase 2, and the crankcase 2 has a bearing seat 6, An oil tank channel 7 connecting the two is arranged between the main oil tank 3 and the auxiliary oil tank 4. The bearing housing 6 includes four crankshaft stamping bearing housings with the same diameter and two crankshaft guide bearing housings with the same diameter. The crankcase 2 is located on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com