Quasi-halbach array outer rotor permanent magnet synchronous gearless traction machine

A gear traction machine and permanent magnet synchronization technology, applied in the direction of synchronous machines, electromechanical devices, electrical components, etc., can solve the problems of low power utilization, complex magnetizing equipment, and complicated magnetizing operations, and achieve overall weight reduction, Reduced moment of inertia and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

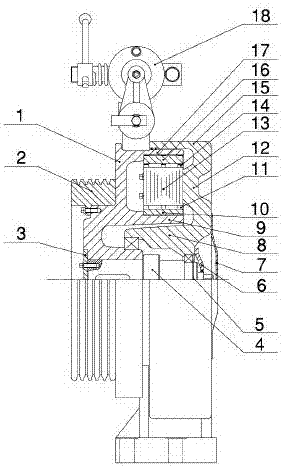

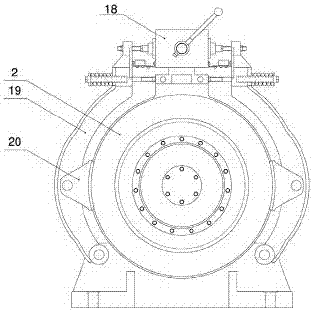

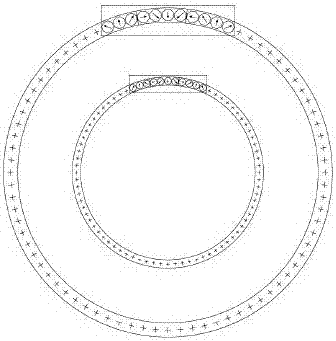

[0035] Such as figure 1 The shown quasi-Halbach array outer rotor permanent magnet synchronous gearless traction machine includes a machine base 15, a rotating shaft 4, an outer rotor, an inner stator 13, a traction wheel 2 and a brake 18; the outer rotor includes a magnet mounting frame 1 and a permanent Magnets, the magnet mounting frame 1 is installed on the rotating shaft 4, and the permanent magnet is arranged around the outer circumference of the inner stator, between the inner stator 13 and the outer shell according to the Halbach array, and is fixedly connected with the magnet mounting frame 1; from figure 1It can be seen from the figure that the structure of the machine base is as follows: there is an outer shell with a ]-shaped cross-section, and the middle part of the outer shell is provided with a rotating shaft installation sleeve 8 protruding into the machine base, and the rotating shaft 4 is installed on the rotating shaft installation sleeve through a bearing....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com