Submicron flake-shaped barium sulfate and preparation method thereof

A barium sulfate, sub-micron technology, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems of low cost and no additives, and achieve the effect of mild process conditions, high purity, low cost and no additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

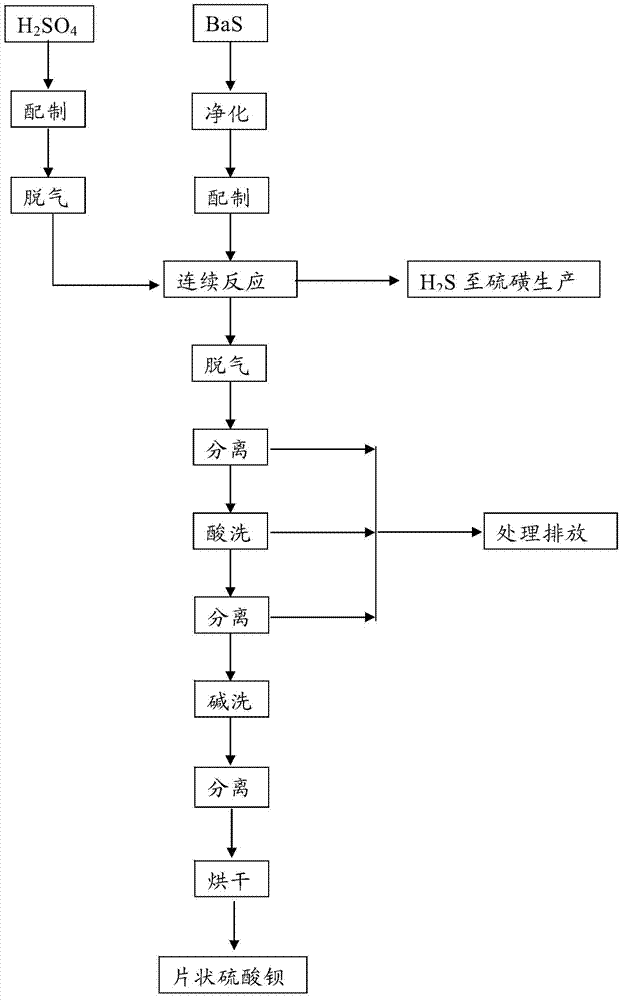

[0041] The invention provides a kind of preparation method of submicron flaky barium sulfate, comprising the steps of:

[0042] (1) Sulfuric acid pretreatment

[0043] Sulfuric acid is made into a sulfuric acid aqueous solution with a concentration of 4.0±0.5mol / L, degassed under stirring, and then cooled and filtered to obtain pretreated sulfuric acid; preferably, the degassing time is 2.5-4 hours, preferably 3 hours; preferably, after cooling to 35°C-40°C, filter; preferably after cooling to 35-40°C, filter with a 1 μm precision filter.

[0044] This step is to carry out the step of pretreatment to the raw material sulfuric acid of producing barium sulfate, and this is the need of obtaining barium sulfate with better whiteness. When blowing, generally clean air is blown in to prevent the nitrogen in it from affecting the quality of sulfuric acid.

[0045] During the sulfuric acid production process, a small amount of nitrogen oxides will be produced and remain in the sulfu...

Embodiment 1

[0083] Lower binding figure 1 The process flow diagram of the present invention illustrates the process of preparing submicron plate-shaped barium sulfate.

[0084] (1) Sulfuric acid pretreatment

[0085] Pour the concentrated sulfuric acid into the 10M 3 In the reaction pot of deionized water, prepare a solution with a sulfuric acid concentration of 4.0mol / L, then blow in purified air, degas for 3 hours under stirring, cool the jacket to 38°C, and filter it with a 1μm precision filter before use .

[0086] (2) Barium sulfide pretreatment

[0087] Add 100L of industrial barium sulfide solution into deionized water to make a barium sulfide solution with a concentration of 71.0g / L, keep the solution temperature at 53°C, and filter it with a 1μm precision filter before use.

[0088] (3) Continuous synthesis

[0089] The BaS solution obtained in step (2) reacts with the sulfuric acid solution obtained in step (1) at a flow rate of 600L / h, while adjusting the H 2 SO 4 The fl...

Embodiment 2

[0094] Lower binding figure 1 The process flow diagram of the present invention illustrates the process of preparing submicron plate-shaped barium sulfate.

[0095] (1) Sulfuric acid pretreatment

[0096] Pour the concentrated sulfuric acid into the 10M 3 Prepare a solution with a sulfuric acid concentration of 4.0mol / L in a reaction pot of deionized water, blow in purified air, degas for 3 hours under stirring, cool the jacket to 39°C, and filter it with a 1μm precision filter before use .

[0097] (2) Barium sulfide pretreatment

[0098] Add 100L of industrial barium sulfide solution into deionized water to make a barium sulfide solution with a concentration of 60.2g / L, keep the solution temperature at 54°C, and filter it with a 1μm precision filter before use.

[0099] (3) Continuous synthesis

[0100] The BaS solution obtained in step (2) reacts with the sulfuric acid solution obtained in step (1) at a flow rate of 580L / h, while adjusting the H 2 SO 4 The flow rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com