Extraction method of rice bran polysaccharide

A technology of rice bran polysaccharide and extraction method, which is applied in the field of extraction of rice bran polysaccharide and traditional Chinese medicine raw materials, can solve the problems of unfavorable industrialization, long time consumption, high production cost, etc., and achieve improved extraction rate and purity, environmental friendliness, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 A kind of extraction method of rice bran polysaccharide

[0034] A method for extracting rice bran polysaccharides, carried out in accordance with the following sequence of steps:

[0035] ① decoction

[0036] Take rice bran, add saturated Ca(OH) 8 to 20 times the mass of rice bran 2 Solution, boiled, kept in a slightly boiling state for 0.5-2 hours, then lowered to room temperature, and completed one decoction; repeated decoction for 1-3 times, filtered, and combined filtrates to obtain decoction P1;

[0037] ② centrifugal

[0038] Take the above-mentioned decoction P1 and perform centrifugation to remove insoluble impurities to obtain supernatant Q1;

[0039] ③ concentrated

[0040] The above supernatant Q1 is placed in a rotary evaporator and concentrated under reduced pressure at 60-100°C to 1 / 10-1 / 3 of the volume / weight of the supernatant Q1 to obtain a concentrated solution C1;

[0041] ④Removal of impurities

[0042] Put the above concentrated...

Embodiment 2-6

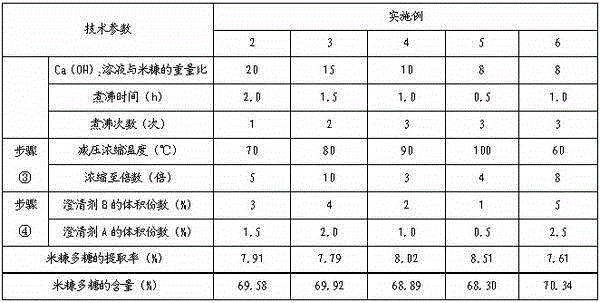

[0048] Example 2-6 Extraction method of rice bran polysaccharide

[0049] Embodiment 2-6 is respectively a kind of extraction method of rice bran polysaccharide, and its difference with embodiment 1 is that the technical parameters involved in the extraction method are different, specifically see the following table:

[0050]

Embodiment 7

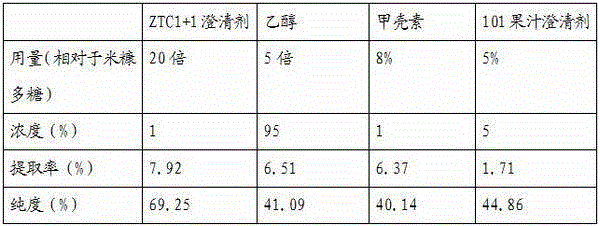

[0051] The selection of embodiment 7 alkaline reagent

[0052] The inventor tries to adopt other alkaline reagents, such as NaOH, KOH, NH 3 etc., to destroy the combination of rice bran polysaccharide and other components, but these alkaline reagents have problems such as inability to remove phytic acid during use, resulting in a decrease in extraction rate and purity. The specific results are shown in the following table:

[0053]

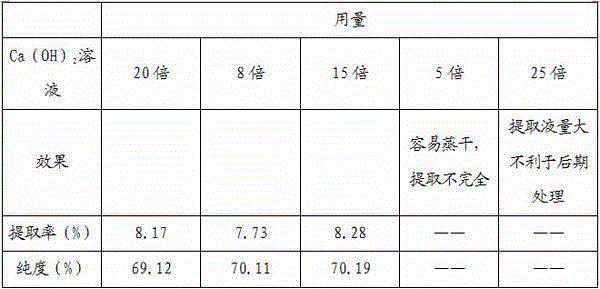

[0054] Simultaneously for Ca(OH) 2 The amount of the solution was investigated, and it was found that when the amount is less than 8 times, it will be easily evaporated to dryness and the extraction will not be complete; while if the amount is more than 20 times, the amount of extract will be large and it will not be easy to process later. The details are shown in the following table:

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com