Manufacturing method of tungsten silicon target material

A manufacturing method and target technology, which are applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems such as the inability to meet the quality requirements of the target material and the low density of the tungsten-silicon target material, and achieve excellent sputtering. The effect of injection performance, fast production speed, and environmental protection and cleanliness in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

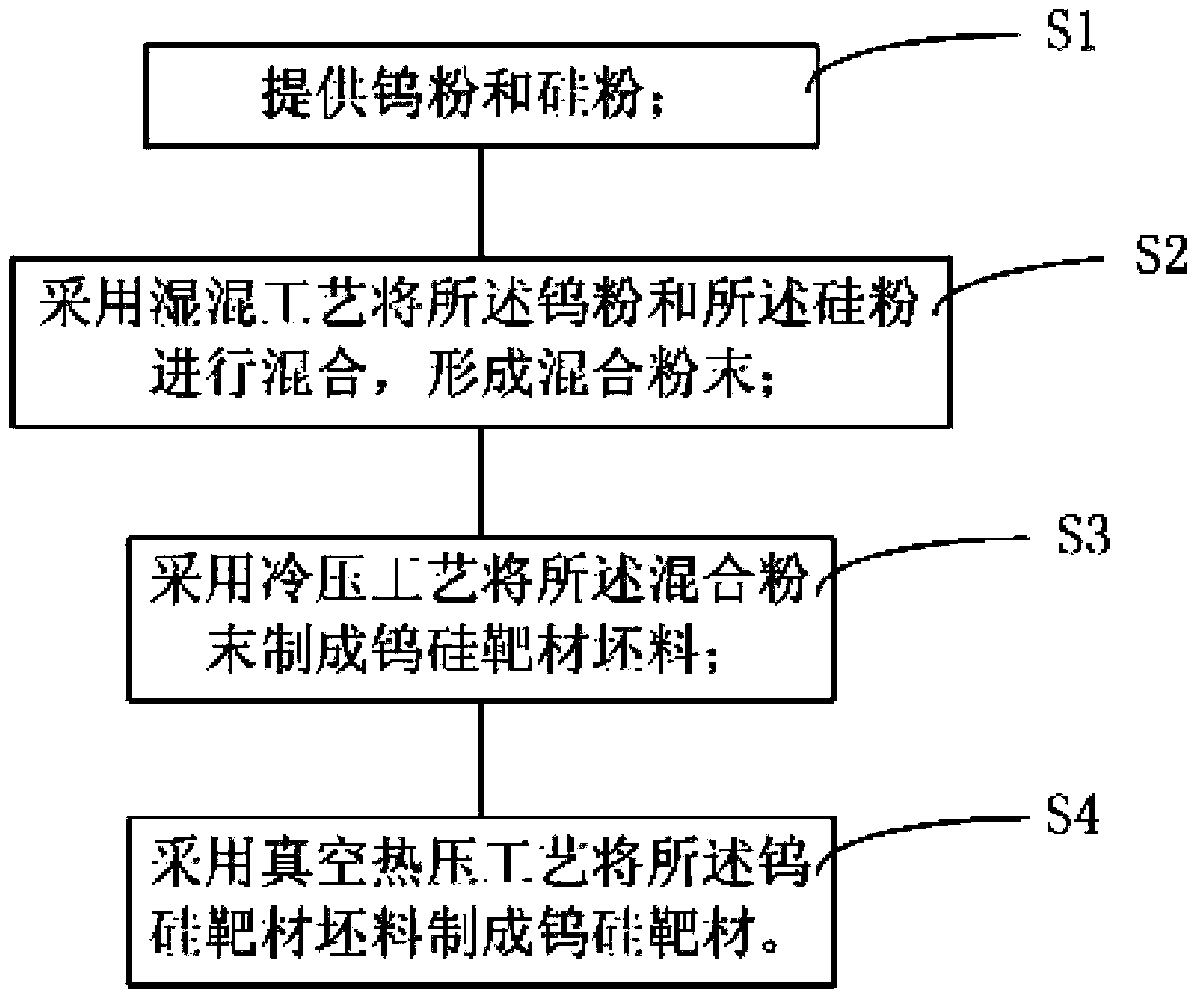

[0031] Please refer to figure 1 , figure 1 It is a flowchart of a method for preparing a tungsten-silicon target according to an embodiment of the present invention. Such as figure 1 As shown, the method for preparing a tungsten-silicon target provided by the embodiment of the present invention mainly includes the following steps:

[0032] Step S1, providing tungsten powder and silicon powder;

[0033] Step S2, using a wet mixing process to mix the tungsten powder and the silicon powder to form a mixed powder;

[0034] Step S3, using a cold pressing process to make the mixed powder into a tungsten-silicon target blank;

[0035] In step S4, the tungsten-silicon target blank is made into a tungsten-silicon target by using a vacuum hot pressing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com