Self-ballast LED (Light Emitting Diode) spot lamp

A LED spotlight and self-ballasting technology, which is applied in lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of complex production and assembly structure, large volume, and low production efficiency, and achieve light weight and volume Small, easy-to-assemble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

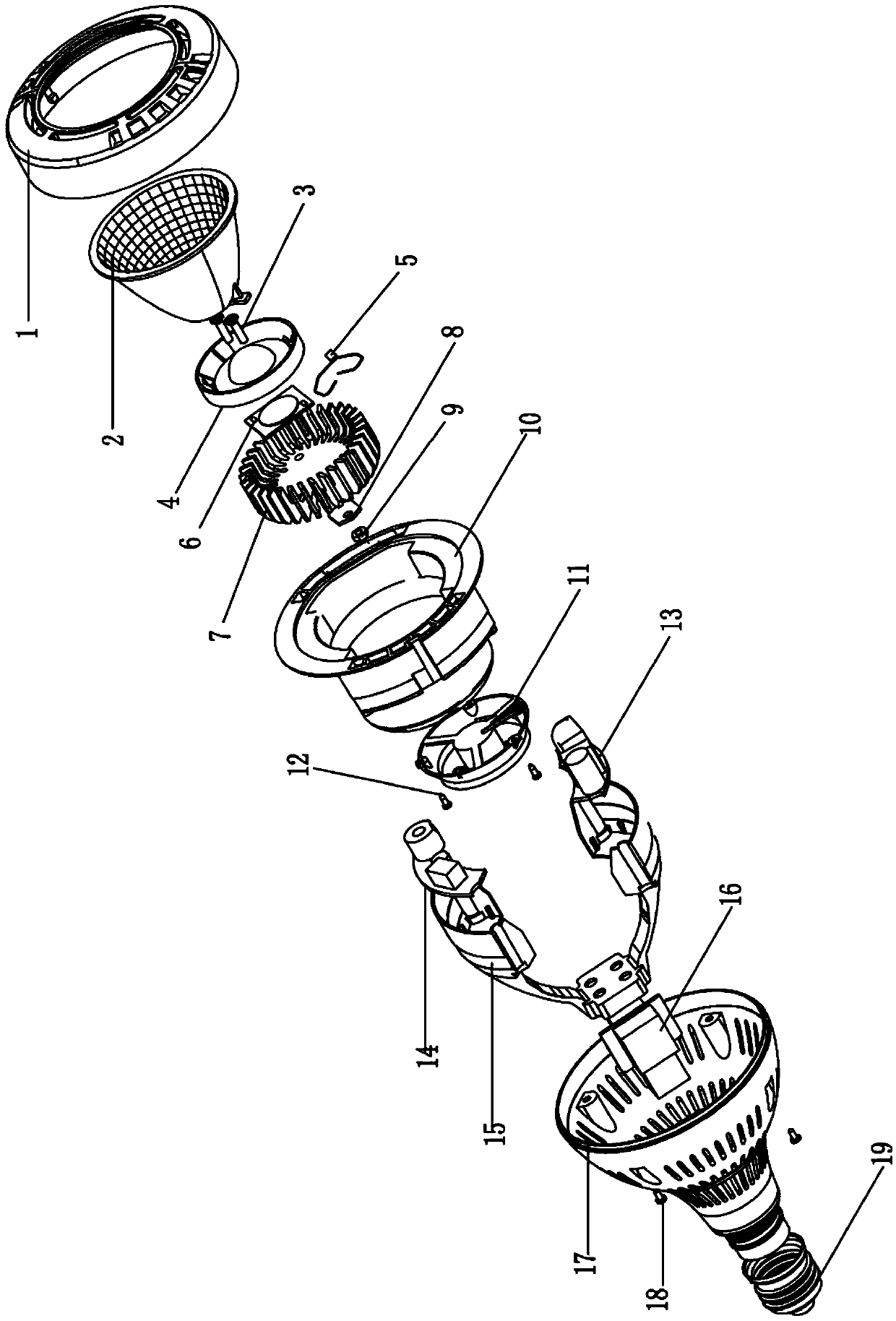

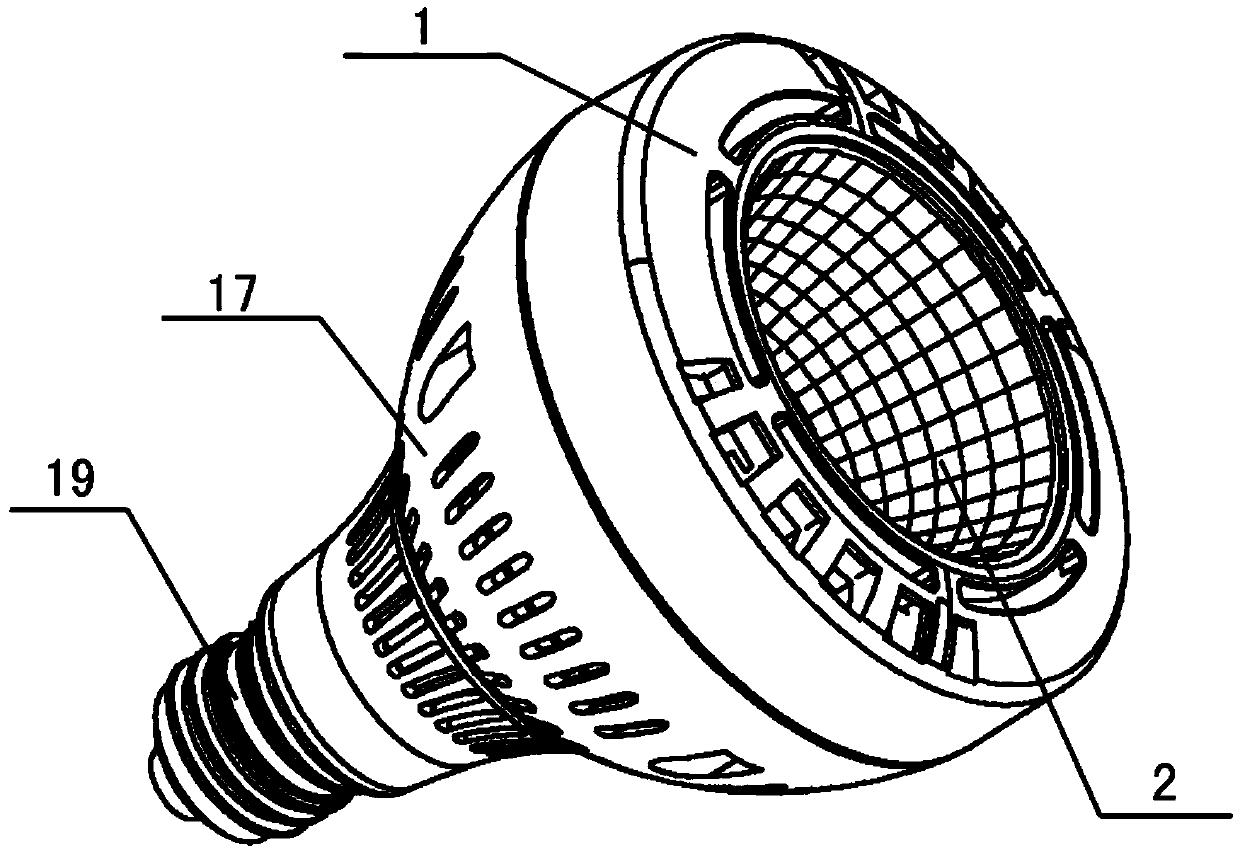

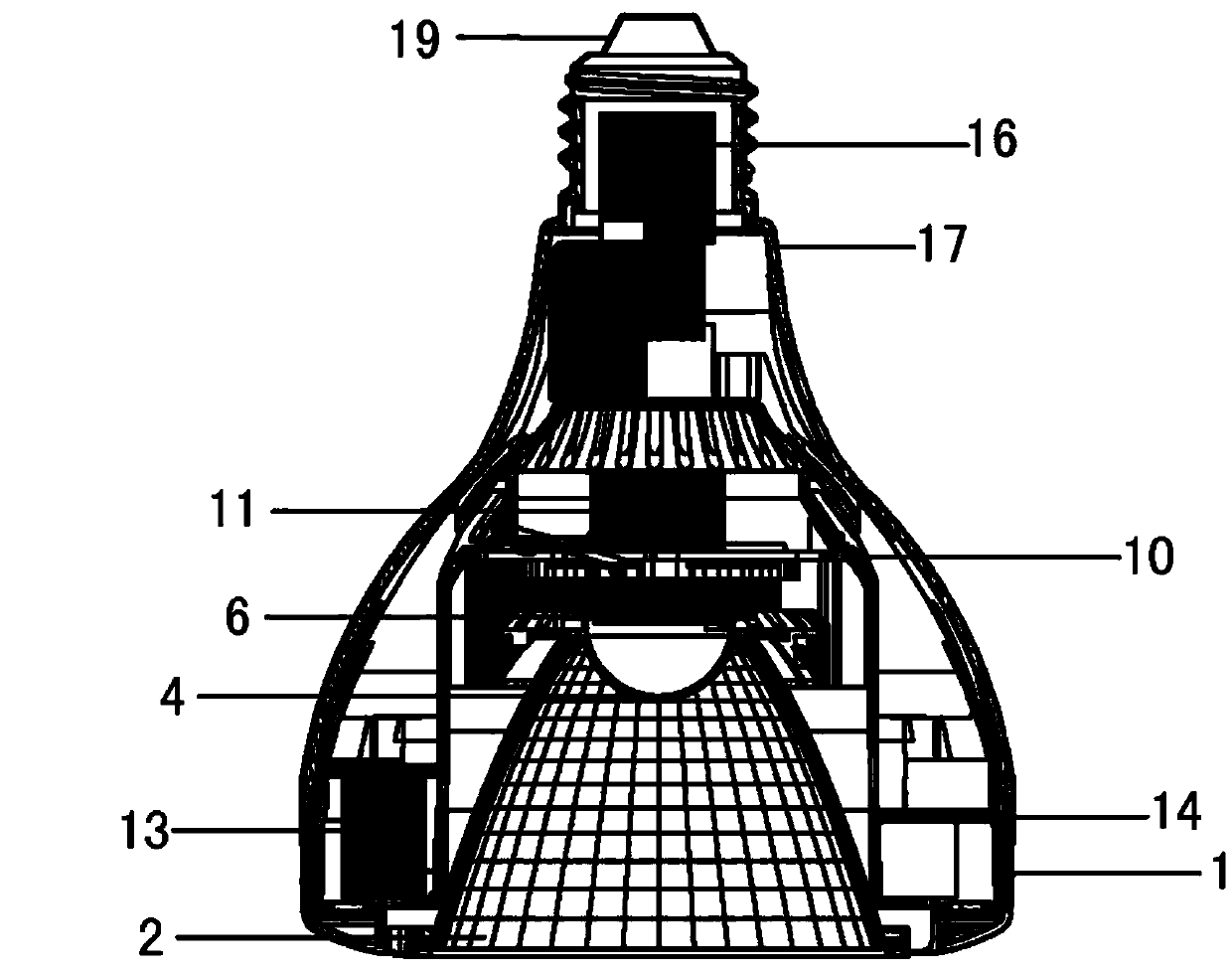

[0024] Please refer to the attached figure 1 to attach Figure 5 , the present invention mainly includes a lamp holder 19, an adapter 17, an air distribution cover 10, a power supply device 13, 14, 16, a fan 11, a lamp body 7, a light source 6, a light source fixing seat 4, a reflector cup 2 and a cover 1, and the lamp holder 19 It is fixedly installed at the rear end of the adapter 17. In this embodiment, the lamp cap 19 adopts an E27 interface lamp cap. During specific implementation, lamp caps of other interface forms can also be used according to actual needs. The power supply device is installed in the adapter 17. In this embodiment, the power supply device has a saddle shape as a whole, or it can also be defined as a "U" shape. The bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com