Micro-cavity interference flow velocity differential-pressure-sensitive structure and flow velocity and quantity sensor with micro-cavity interference fiber

A technology of flow sensor and sensitive structure, which is applied in the direction of fluid velocity measurement, velocity/acceleration/shock measurement, flow/mass flow measurement, etc. It can solve the problems of measurement sensitivity drop, influence of measurement accuracy, polarization signal fading, etc., and achieve the elimination of polarization Signal fading, high measurement sensitivity, and the effect of eliminating interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

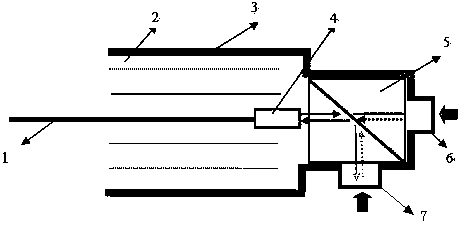

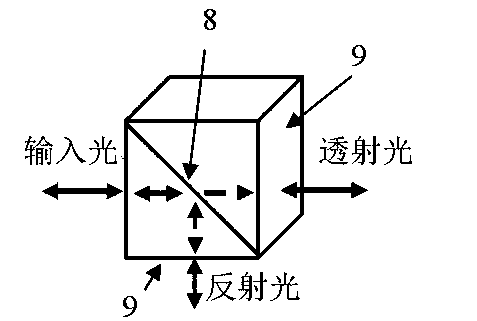

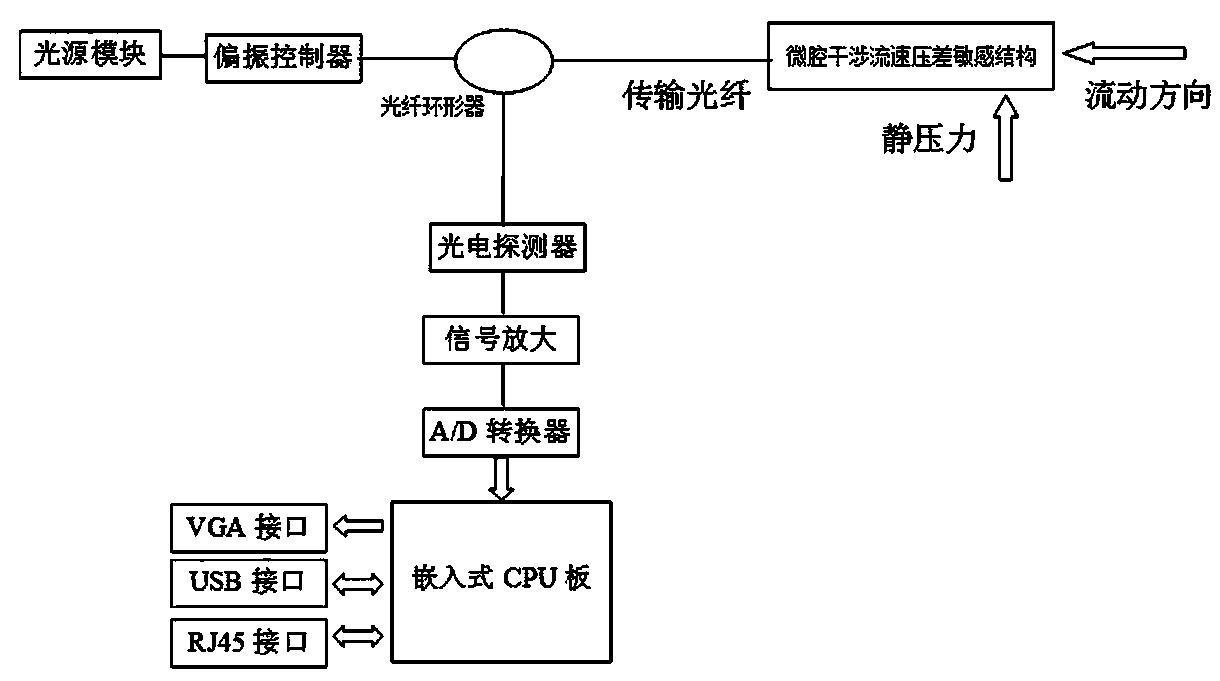

[0051] The microcavity interference flow rate pressure difference sensitive structure of this embodiment includes a transmission optical fiber, a housing, an optical fiber collimator disposed in the housing, and a light beam splitting cube; the light beam splitting cube is connected to and sleeved on the housing The first pressure-sensitive diaphragm for sensing hydrostatic pressure and the second pressure-sensitive diaphragm for sensing fluid velocity pressure; the optical fiber collimator collimates the light wave signal in the transmission fiber and outputs it to the optical beam splitting cube , and the interference light wave signal generated by the reflection of the first and second pressure-sensitive diaphragms is coupled into the transmission fiber; The reflected light of the sensitive diaphragm interferes to form an interference light wave signal carrying flow velocity and pressure difference information.

Embodiment 2

[0053] The microcavity interference flow rate pressure difference sensitive structure of this embodiment includes a transmission optical fiber, a housing, an optical fiber collimator disposed in the housing, and a light beam splitting cube; the light beam splitting cube is connected to and sleeved on the housing The first pressure-sensitive diaphragm for sensing hydrostatic pressure and the second pressure-sensitive diaphragm for sensing fluid velocity pressure; the optical fiber collimator collimates the light wave signal in the transmission fiber and outputs it to the optical beam splitting cube , and the interference light wave signal generated by the reflection of the first and second pressure-sensitive diaphragms is coupled into the transmission fiber; The reflected light of the sensitive diaphragm interferes to form an interference light wave signal carrying flow velocity and pressure difference information; the housing is filled with packaging filling materials for stabl...

Embodiment 3

[0055]The microcavity interference flow velocity and pressure difference sensitive structure of this embodiment includes a transmission optical fiber, a housing, a self-focusing lens arranged in the housing, and a light beam splitting cube; the light beam splitting cube is connected to and sleeved on the housing. The first pressure-sensitive diaphragm for sensing hydrostatic pressure and the second pressure-sensitive diaphragm for sensing fluid velocity pressure; the self-focusing lens collimates the light wave signal in the transmission fiber and outputs it to the light beam splitting cube, And the interference light wave signal generated by reflecting back the first and second pressure-sensitive diaphragms is coupled into the transmission fiber; the light beam splitting cube divides the output light of the self-focusing lens into two beams, and makes the first and second pressure-sensitive diaphragms The reflected light of the sheet interferes to form an interference light wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com