Device and method for measuring height of micro-amplitude liquid surface wave in real time

A liquid surface, real-time measurement technology, used in measurement devices, liquid/fluid solid measurement, liquid level indicators, etc., can solve the problem of inability to accurately measure the amplitude of micro-amplitude liquid surface waves, and achieve simple structure, high precision, and precision. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

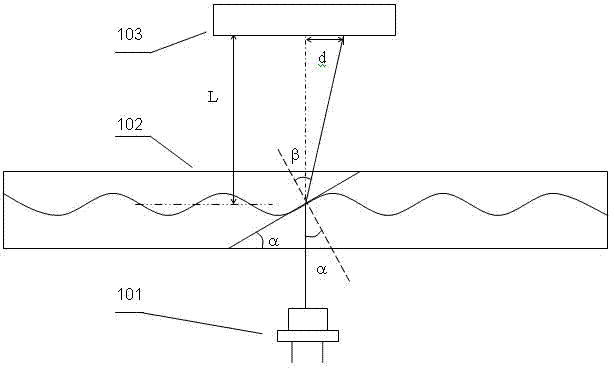

[0016] figure 1 It is a schematic diagram of the measurement principle of the present invention. The laser 101 emits laser light vertically upward from the bottom of the transparent liquid tank 102. After the laser light emerges from the liquid surface, the light oscillates with the surface waves of the liquid, and the emitted light hits the photoelectric light placed horizontally at a distance L above the liquid surface. The photosensitive surface of the position sensor 103 .

[0017] The waveform of the micro-amplitude liquid surface wave is approximately a sine wave, and the trace of the wave surface undulation can be used A sin( kx-ωt+δ ) means, in the formula, A is the liquid surface wave amplitude, x is the position coordinate in the propagation direction of the liquid surface wave, k is the wave number, ω is the angular frequency of the liquid surface wave, t for time, δ is the initial phase of the liquid surface wave. Depend on figure 1 It can be known th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com