Full-automatic mouse function testing equipment and full-automatic mouse function testing method

A technology of automatic testing and functional testing, applied in the field of mouse testing, can solve the problems of low degree of automation, inability to test key parameters, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

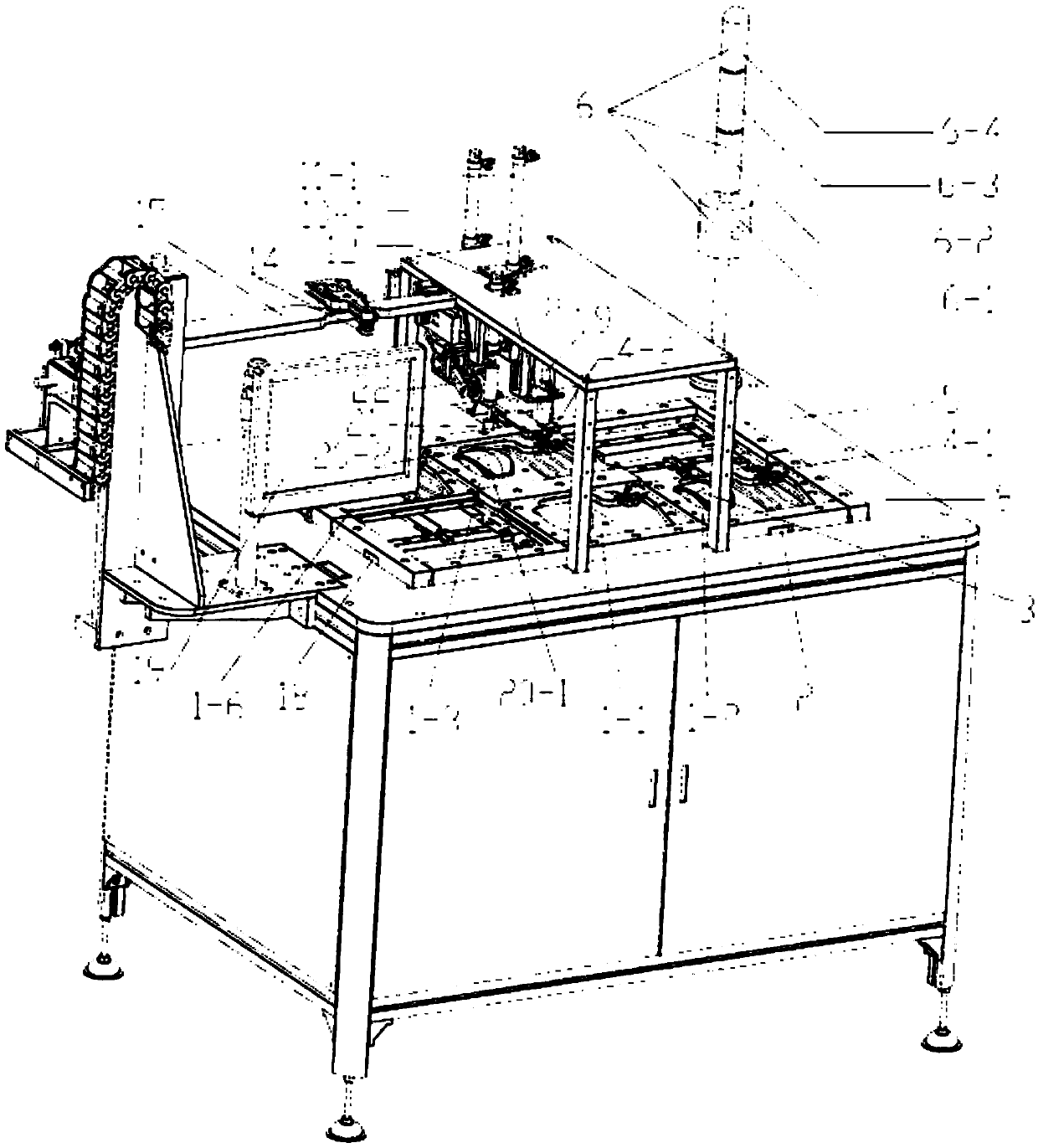

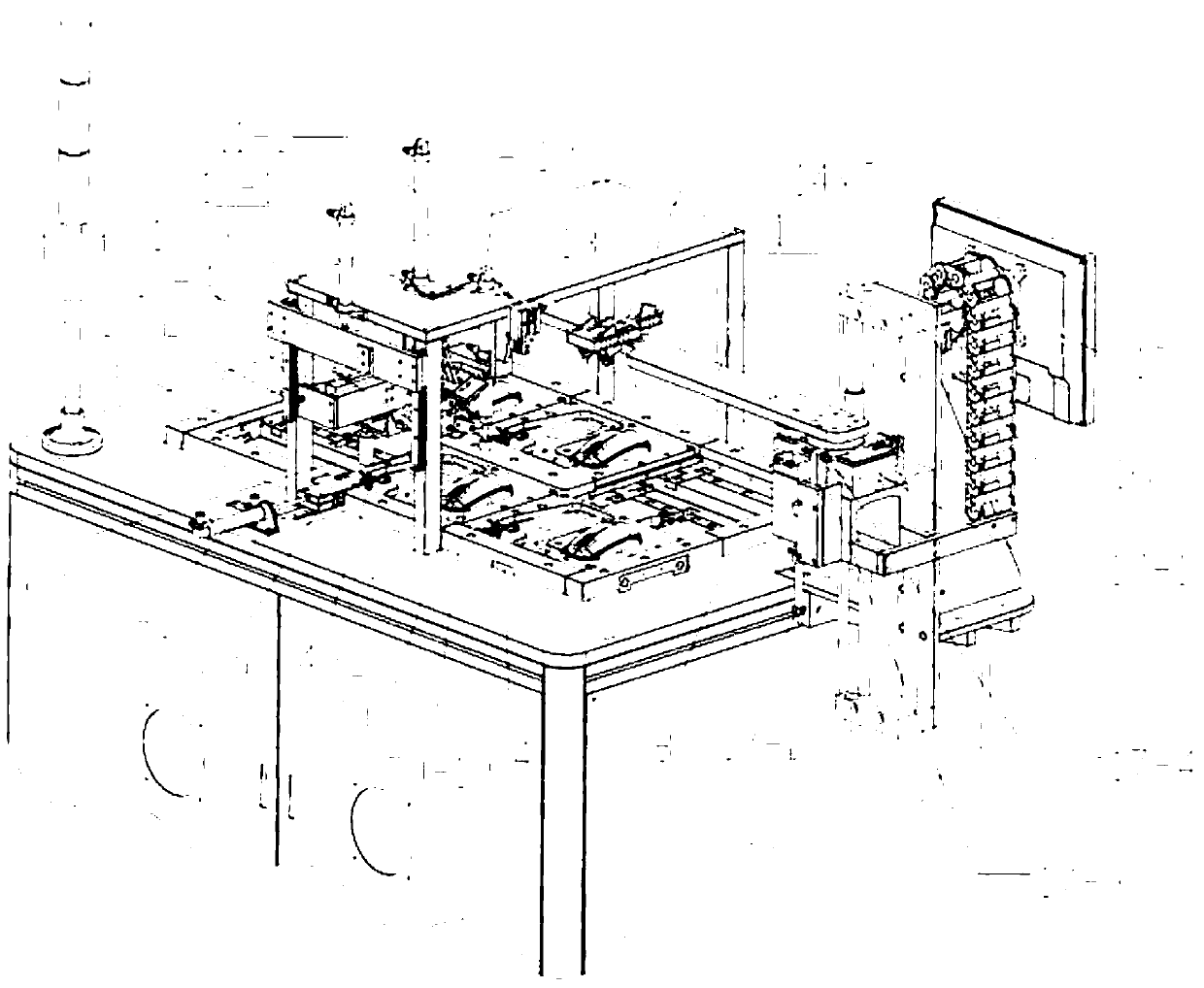

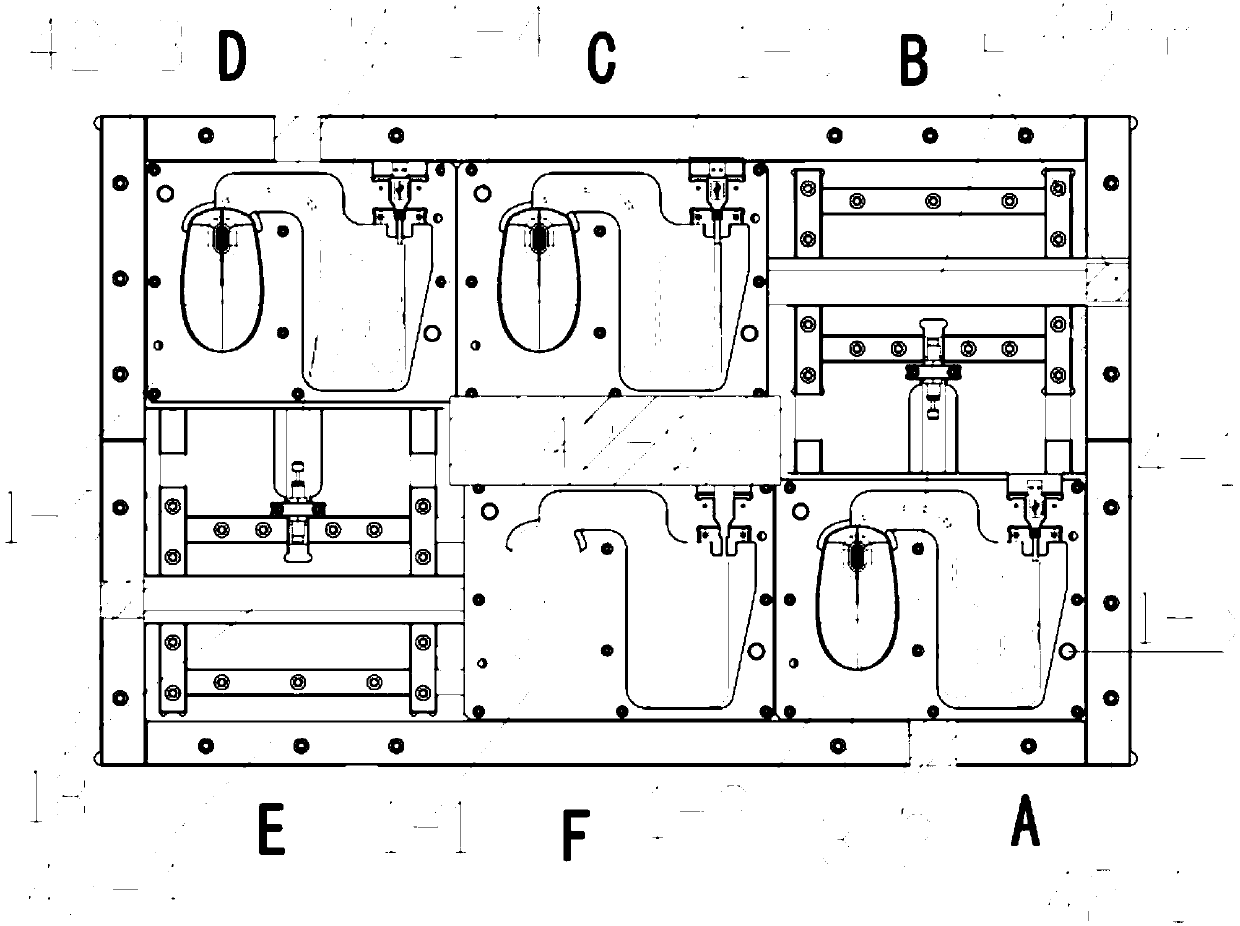

[0110] The invention discloses a mouse function full-automatic testing device, which adopts a single-chip micro-control center (MCU) as a main control center, and a computer communication program as a coordinating unit for control. In the present invention, two motors are used to test the mouse wheel and the linearity respectively, the linearity is tested when one motor rotates, and the roller is tested when the other motor rotates.

[0111] Mouse function automatic test equipment includes circular transmission action module, vehicle positioning module, mouse positioning module, mouse CABLE positioning module, mouse CABLE head insertion module, wheel function test action module, linear function test action module group, common key function test action module, mechanism manual action module, display 19, computer, alarm 6; in addition, the test equipment also includes a number of electrical control modules, mouse test program, computer communication program, electrical control T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com