Wideband sound absorption structure combing mechanical impedance of composite resonance cavities with micropunch plates

A mechanical impedance, micro-perforated plate technology, applied in the direction of sound-producing instruments, instruments, etc., can solve the problems of poor high-frequency sound absorption, complex structure, occupying a large space, etc., and achieve the effect of sound absorption frequency bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

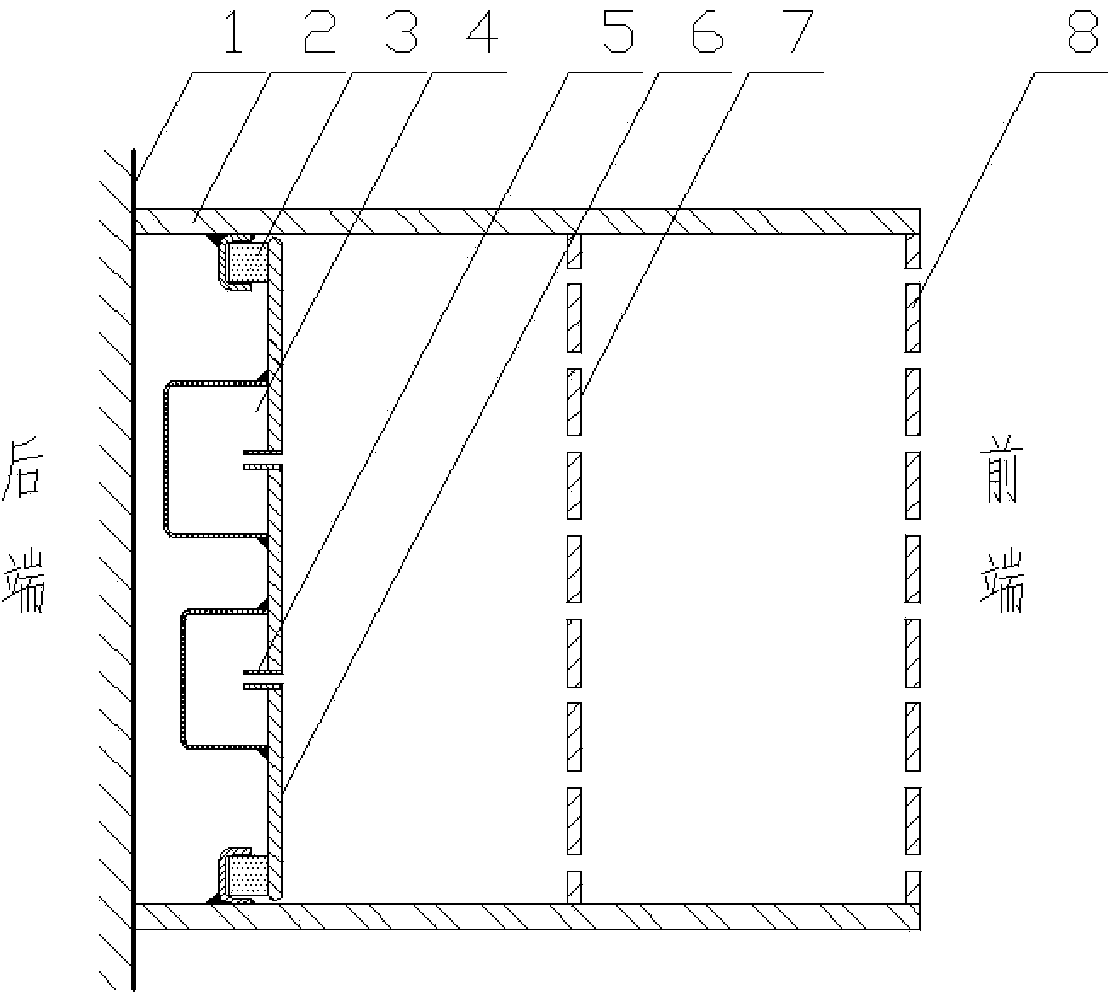

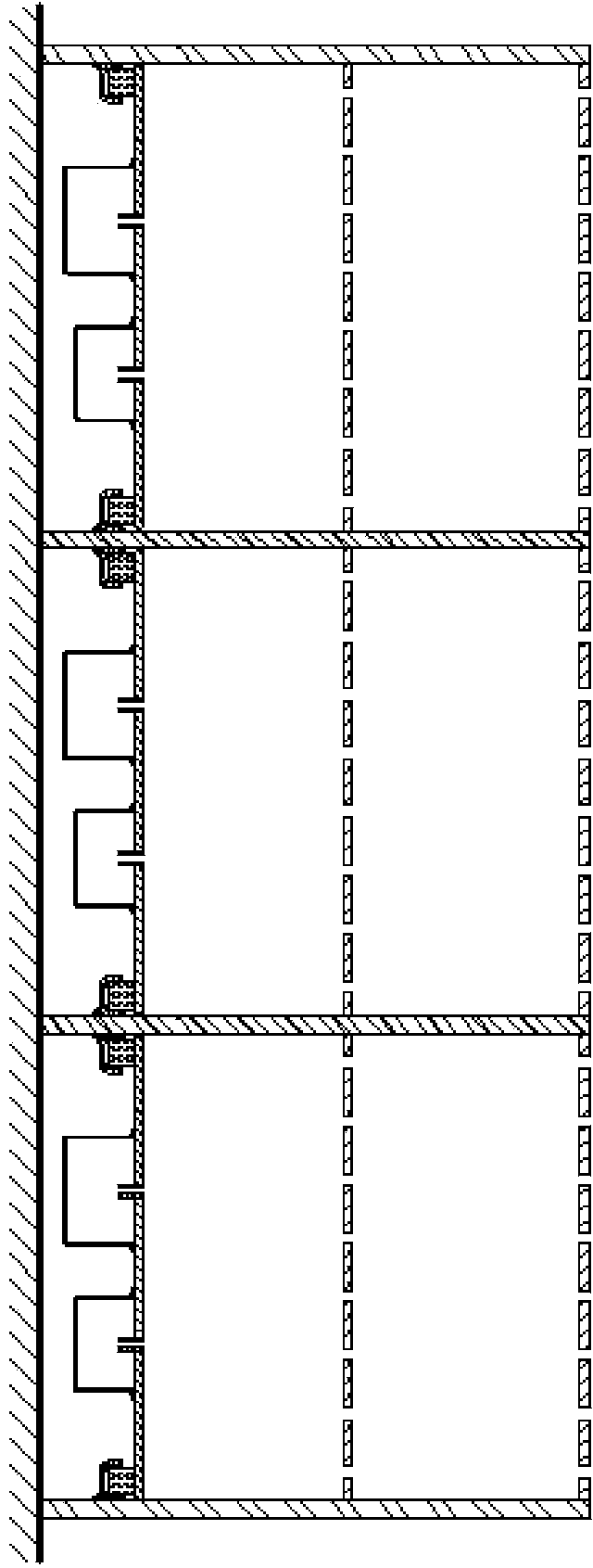

[0018] combined with figure 1 And attached figure 2 The implementation method of the present invention will be described.

[0019] attached figure 1 It is the basic structural diagram of the present invention. The bracket is installed on the wall 1, and the bracket 2 is made of a metal plate with a thickness of 1mm; the side of the bracket 2 is welded with a small groove, and the whole circle is welded; the viscoelastic ring 3 is placed in the small groove, and the elastic ring is made of viscoelastic material. The shape is rectangular; the mechanical impedance plate is bonded with an adhesive on the elastic ring, and the composite mechanical impedance plate is composed of the mechanical impedance plate 6, the resonant cavity 4 and the intubation tube 5, and the resonant cavity 4 and the intubation tube 5 are connected On the mechanical impedance plate 6; tight bonding is required between the viscoelastic ring 3 and the groove and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com