High efficiency linear topology structure LED (Light Emitting Diode) driving circuit

A technology of LED drive and linear topology, applied in the direction of lamp circuit layout, electric light source, lighting device, etc., can solve the problem of low power factor, achieve the effect of improving power factor, expanding the input voltage range, and realizing constant current output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

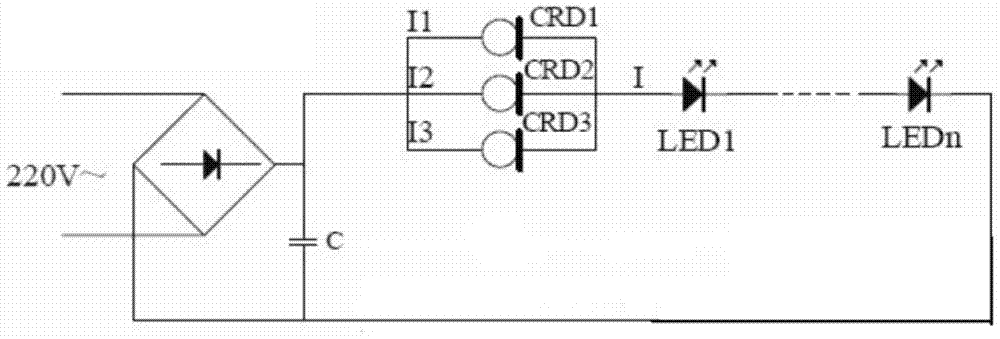

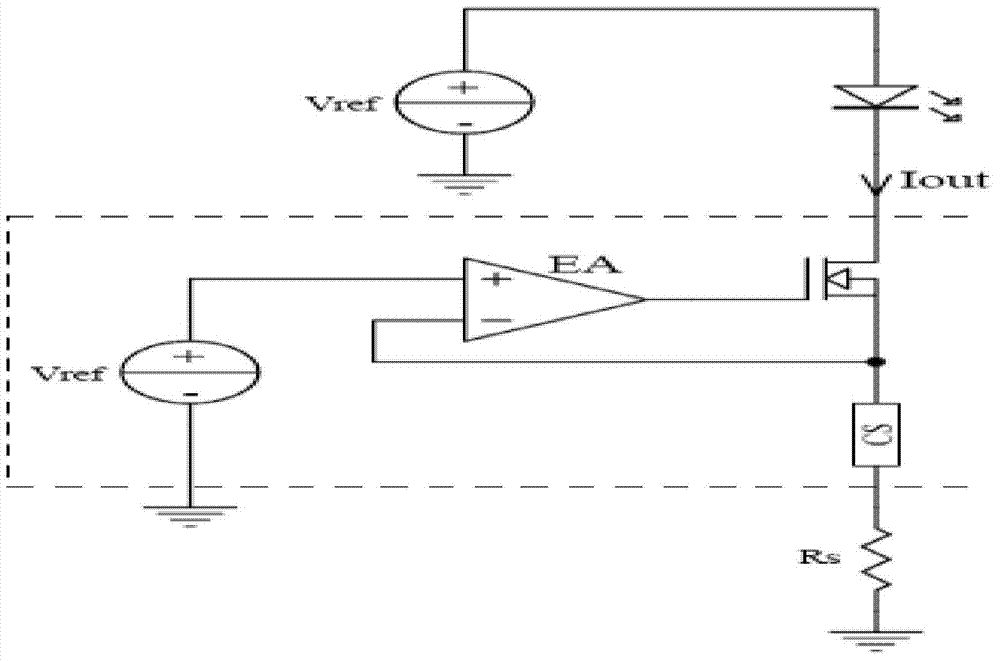

Problems solved by technology

Method used

Image

Examples

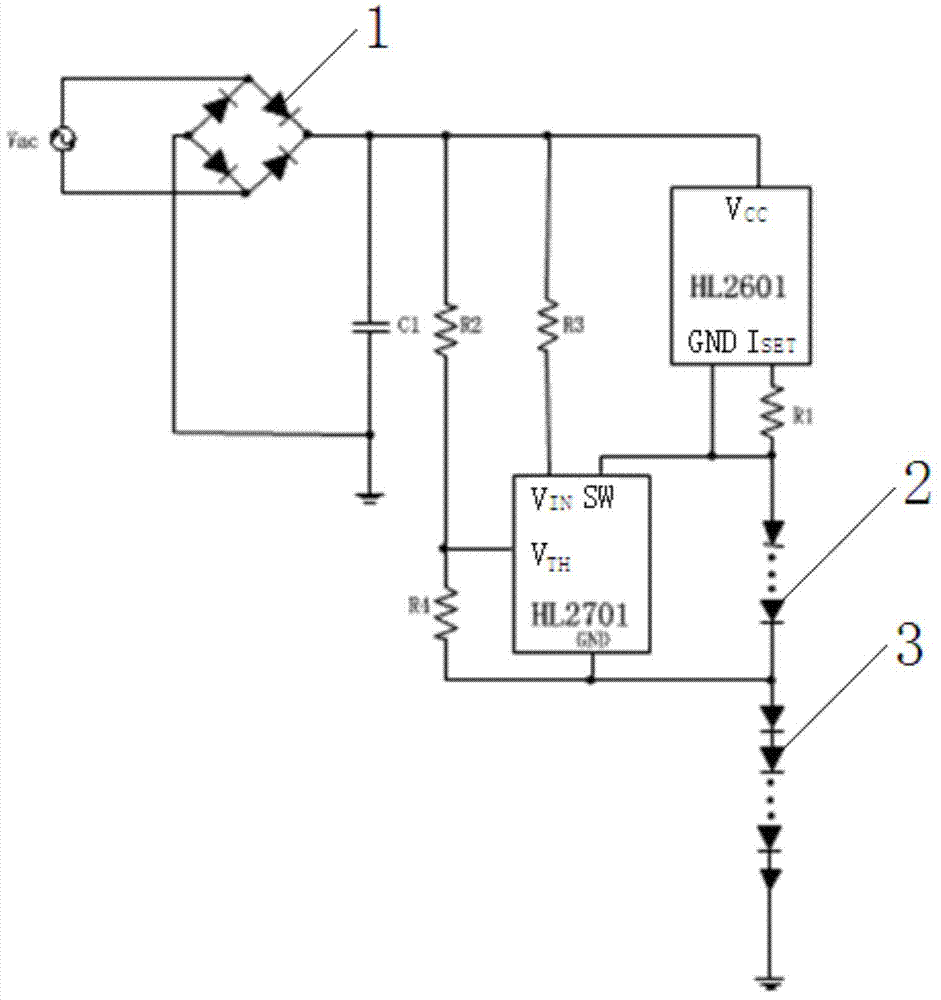

Embodiment 1

[0023] refer to image 3 , Figure 4 , Figure 5 , a high-efficiency linear topology LED drive circuit, including a rectifier bridge 1, a linear IC regulator HL2601 for controlling constant current output, and a main light string 3, and an input capacitor is connected between the positive output terminal and the negative output terminal of the rectifier bridge 1 C1, the linear IC regulator HL2601 includes a power switch tube SW2, the input terminal of the power switch tube SW2 is V CC terminal, which is connected with the positive output terminal of the rectifier bridge 1, and the output terminal of the power switch tube SW2 is I SET terminal, on which is connected an external resistor R1 for setting the current of the LED, the other end of the external resistor R1 is connected to the GND terminal of the linear IC regulator HL2601, between the linear IC regulator HL2601 and the main light string 3 An intelligent switch regulating circuit with optimized constant current outp...

Embodiment 2

[0029] refer to Figure 7 The difference between this embodiment and the first embodiment is that the intelligent switch regulator circuit is composed of two serially connected intelligent switch regulators, which allows more options for linear LED drive. External resistor divider R3 and R4 control the V of the smart switching regulator HL2701(1) TH terminal voltage, resistor divider R5 and R6 control the V of the smart switching regulator HL2701(2) TH terminal voltage. The GND terminal of the linear IC regulator HL2601 is connected to the SW terminal of the intelligent switching regulator HL2701(1), the GND terminal of the intelligent switching regulator HL2701(1) chip is connected to the SW terminal of the intelligent switching regulator HL2701(2), and the external resistor R1 is used to set the current of the LED. R2 and R7 are the V of the smart switching regulator HL2701(1) and the smart switching regulator HL2701(2) respectively. IN Terminal provides operating curre...

Embodiment 3

[0031] refer to Figure 8 , the difference between this embodiment and Embodiment 1 is that the intelligent switch regulator circuit is composed of three series-connected intelligent switch regulators, this architecture can use a very small input capacitance behind the bridge stack, so as to obtain Higher power factor. External resistor divider R3 and R4 control the V of the smart switching regulator HL2701(1) TH terminal voltage, resistor divider R5 and R6 control the V of the smart switching regulator HL2701(2) TH terminal voltage, resistor divider R9 and R10 control the V of the smart switching regulator HL2701(3) TH terminal voltage. The GND terminal of the linear IC regulator HL2601 is connected to the SW terminal of the intelligent switching regulator HL2701(1), and the external resistor R1 is used to set the current of the LED. R2, R7 and R8 are respectively the V of the smart switching regulator HL2701(1), smart switching regulator HL2701(2) and smart switching reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com