Propylene/Ethylene Copolymer Films for Heat Sealing

A random copolymer, ethylene technology, used in lining/interior coating, other chemical processes, transportation and packaging, etc., can solve problems affecting sealing parameters, hardness and gloss reduction, etc., to achieve improved optical properties, low hot tack Effect of initiation temperature, improved optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

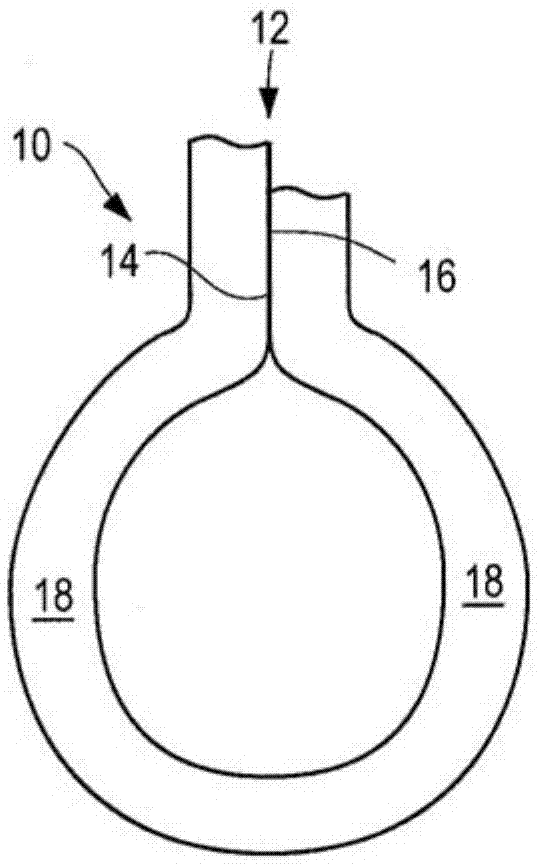

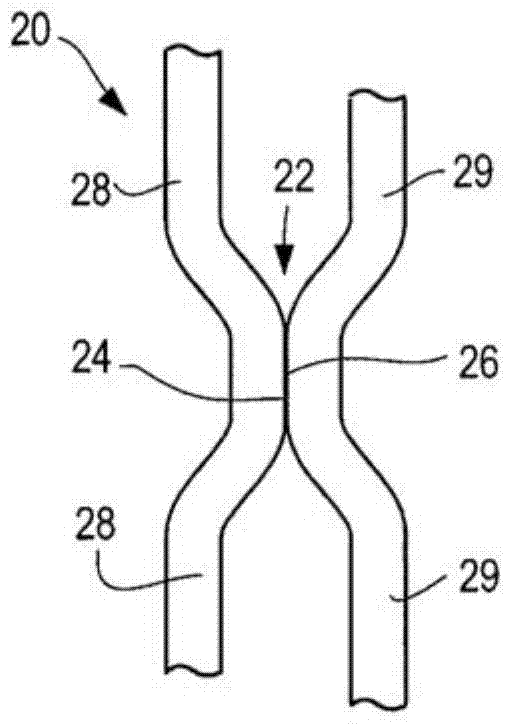

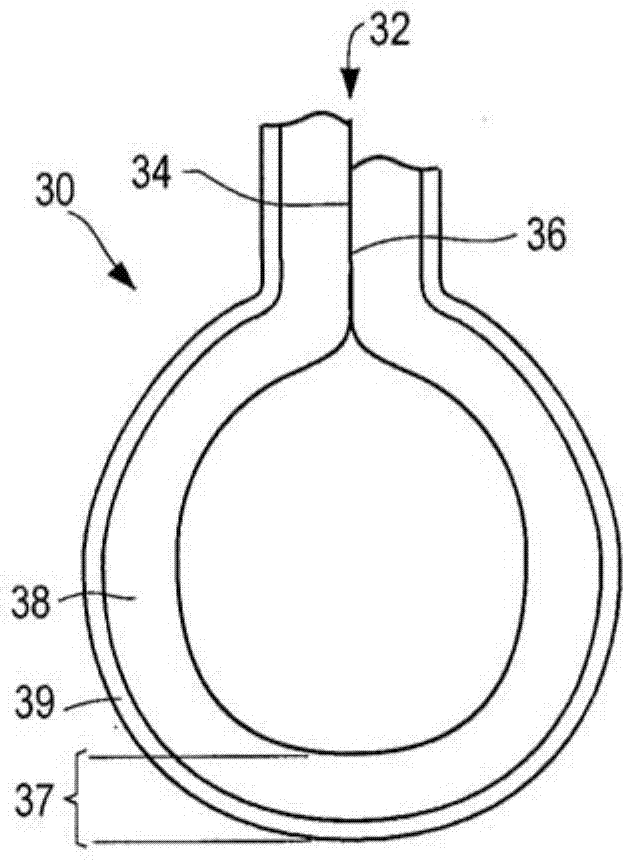

Image

Examples

Embodiment 1

[0134] 2. Embodiment 1 and comparative sample 7

[0135] A. Example 1 - Synthesis of SPAD-containing procatalyst compositions

[0136] 351 g of mixed magnesium / titanium halide alkoxide were stirred in a mixture of 1.69 kg chlorobenzene and 4.88 kg titanium(IV) chloride at ambient temperature. After 10 minutes, a solution of 164.5 g of 5-tert-butyl-3-methyl-1,2-phenylene dibenzoate in 750 mL of chlorobenzene was added, followed by 0.46 kg of chlorobenzene. The mixture was stirred at 100°C for 60 minutes, allowed to stand, and then filtered at 100°C. The solid was stirred in 3.16 kg chlorobenzene at 70°C for 15 minutes, allowed to stand, then filtered at 70°C. The solid was stirred in a mixture of 2.36 kg chlorobenzene and 4.84 kg titanium(IV) chloride and after 10 minutes 109.7 g of 5-tert-butyl-3-methyl-1,2-phenylene dibenzoate were added Solution in 416 g chlorobenzene, followed by 0.20 kg chlorobenzene. The mixture was stirred at 105-110°C for 30 minutes, allowed to stan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com