Photovoltaic cell and method of manufaturing such a cell

A technology of photovoltaic cells and dielectric layers, applied in photovoltaic power generation, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

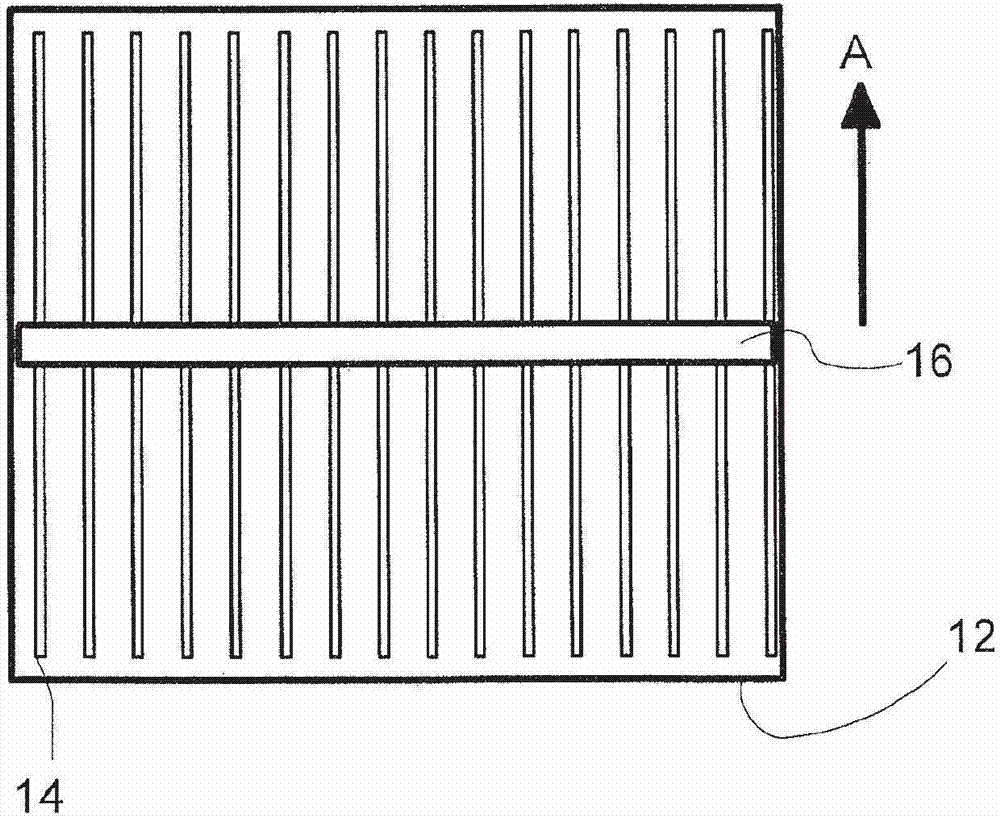

[0030] figure 1 A plan view of the upper surface of a photovoltaic cell comprising an electrode structure 10 with conductive material above a semiconductor body 12 is shown. For example, an electrode structure with a plurality of fingers 14 and a bus bar 16 is shown. The fingers 14 extend from the bus bar 16 along the length direction of the fingers 14 indicated by arrow A. As shown in FIG.

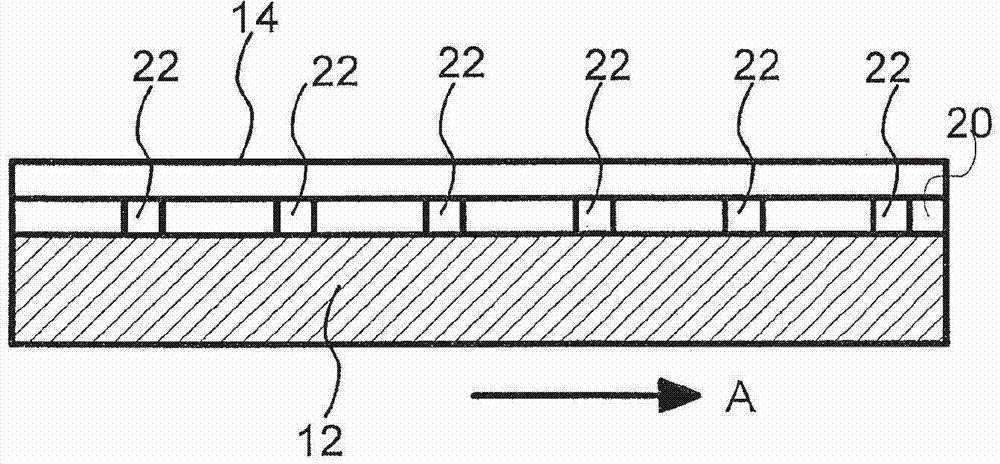

[0031] figure 2 A schematic cross-section through the finger 14 in this direction is shown. A dielectric layer 20 is arranged above the semiconductor body 12 . Between the fingers 14 and the semiconductor body 12 a plurality of contacts 22 are provided through the dielectric layer 20 . The contacts 22 are made of a fire through material, ie usually of sintered conductor grains.

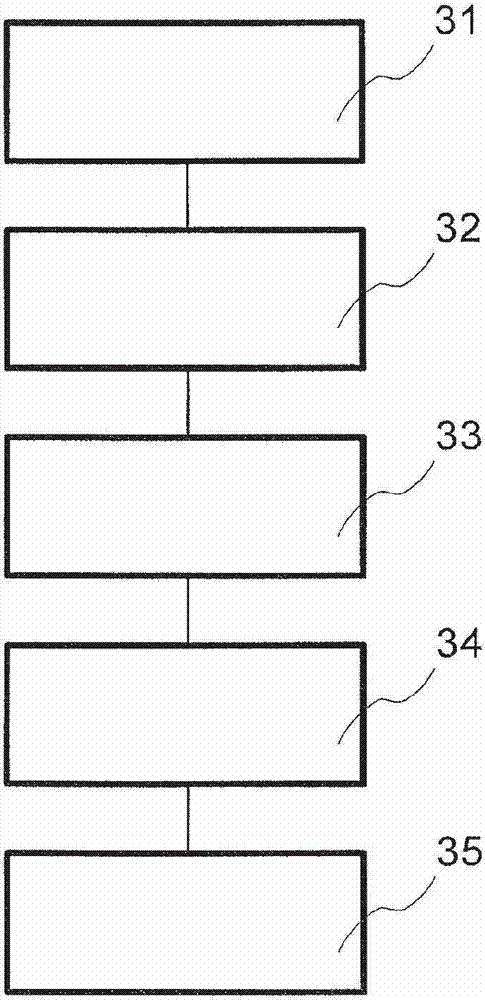

[0032] image 3A flowchart showing a process for making photovoltaic cells. After several conventional preliminary steps, symbolically identified as first step 31 , the process provides an intermediate pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com