Sensitization method for PbS thin film, infrared photoelectric detector and preparation method thereof

An electrical detector, infrared light technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of low sensitivity of infrared photodetectors, unsatisfactory sensitization effect, complex operation process, etc., to eliminate Potential safety hazards, short response time, low sensitization temperature effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

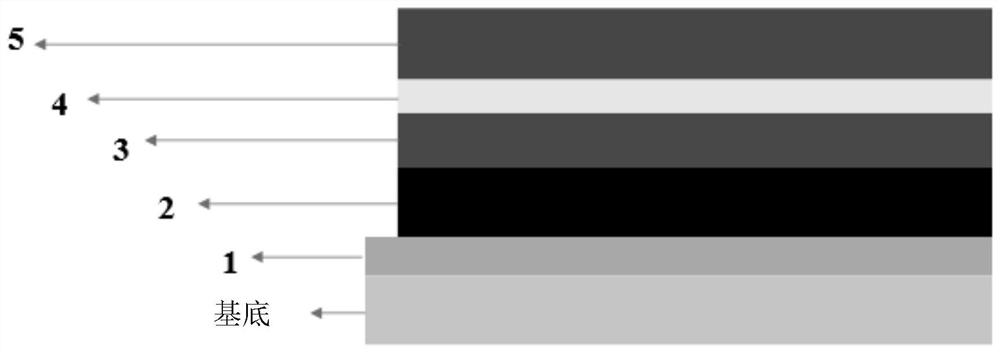

[0050] The preparation method of the near-infrared photodetector based on PbS thin film of the present invention, comprises the steps:

[0051] S1: PbS thin film is prepared on conductive glass or silicon wafer substrate.

[0052] Specifically, the PbS thin film can be prepared by chemical water bath deposition method, and its thickness is 500-700nm. In addition, PbS thin films can also be prepared by magnetron sputtering and ion beam sputtering. When prepared by chemical water bath deposition method, the process is as follows:

[0053] Fully clean the ITO transparent conductive glass, store it in a petri dish, and put the petri dish into an oven to dry for later use.

[0054] Weigh NaOH, CS(NH 2 ) 2 , Pb(NO 3 ) 2 And prepare NaOH concentration to be 0.1M (mol / L), CS (NH 2 ) 2 The concentration is 60mM(mmol / L), Pb(NO 3 ) 2 A solution with a concentration of 9mM (mmol / L). Slowly add Pb(NO 3 ) 2 Solution, continue to stir until the solution is transparent, soak the ...

Embodiment 1

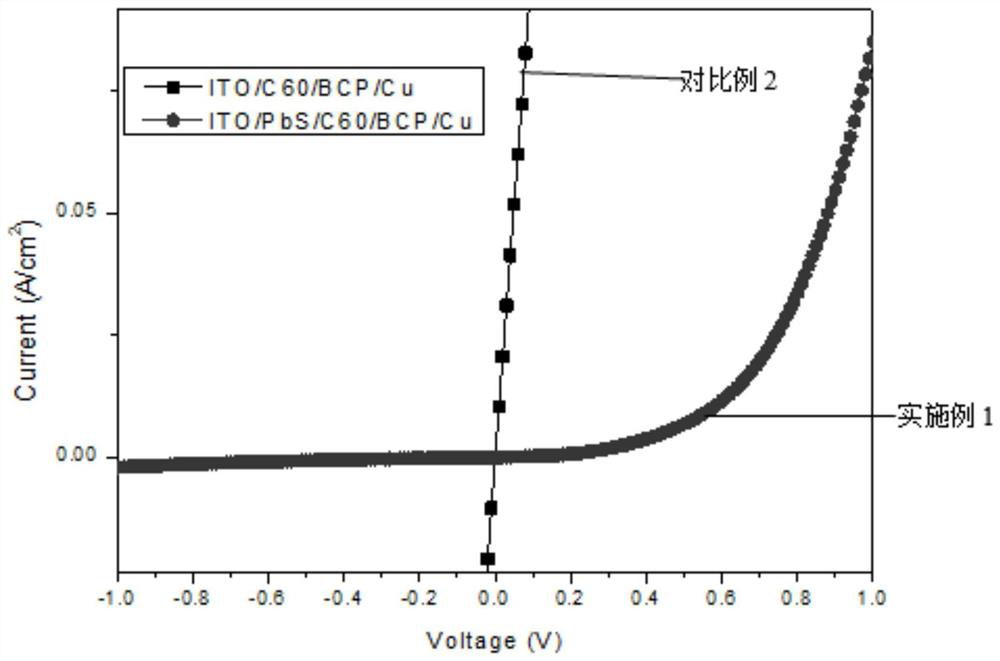

[0067] The invention provides a kind of preparation method based on the near-infrared photodetector of PbS film, comprises the steps:

[0068] S1: A PbS thin film is prepared on an ITO conductive glass substrate, the process is as follows:

[0069] Take a piece of ITO transparent conductive glass with a size of 14.9mmx10mm, a thickness of about 135nm, a square resistance of less than 15 ohms, and a transmittance greater than 86%. First soak the ITO transparent conductive glass in deionized water and put it in an ultrasonic cleaner for 10 minutes. minutes, repeat the operation twice. Then ultrasonically clean the ITO transparent conductive glass bubbles in acetone for 10 minutes, and repeat twice. Finally, ultrasonically clean the ITO transparent conductive glass bubbles in isopropanol for 10 minutes / time, twice. The cleaned ITO transparent conductive glass is taken out and stored in a petri dish, and the petri dish is put into an oven to dry for later use.

[0070] Weigh Na...

Embodiment 2

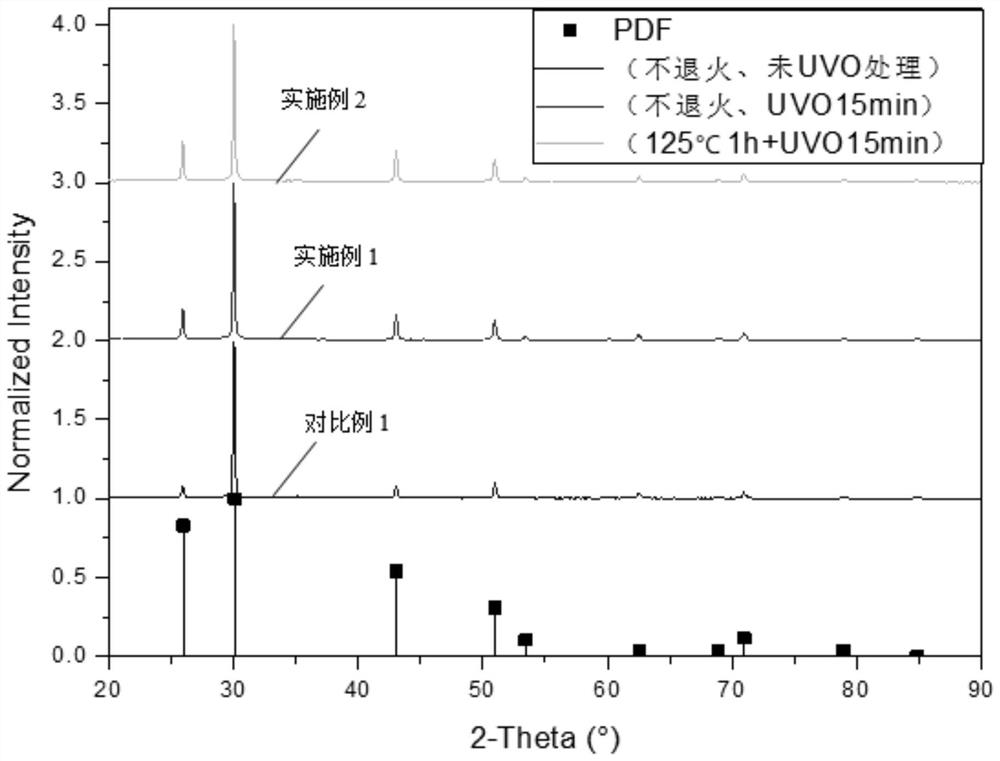

[0076] The difference between Example 2 and Example 1 is that after the PbS film is prepared on the ITO transparent conductive glass in step S1, the PbS film is annealed in air at 125° C. for 1 h to promote the growth of PbS crystal grains, and then according to Example The steps, methods and conditions of S2-S5 in 1 are processed in the same way. After the treatment, the microscopic morphology of the PbS thin film is as follows: Figure 5 shown. It can be seen from the figure that the PbS grain size at this time is uniform, the grain size is large, and the crystallinity is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com