Environment-friendly water-based latex coagulator and preparation method of rubber coating product

A water-based latex and rubber coating technology, applied in textiles and papermaking, gloves, clothing, etc., can solve the problems of flammable and explosive production workers' bodies, environmental pollution, and hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

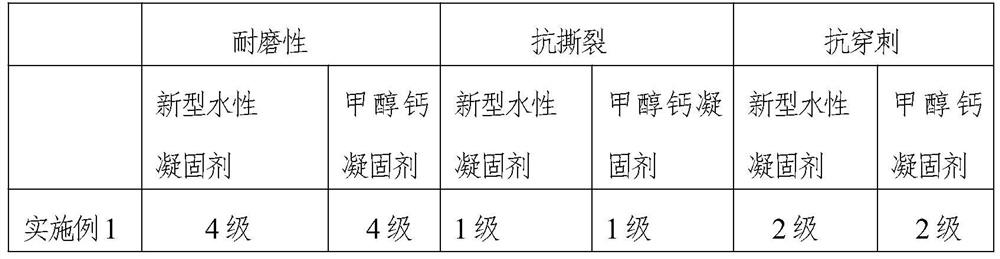

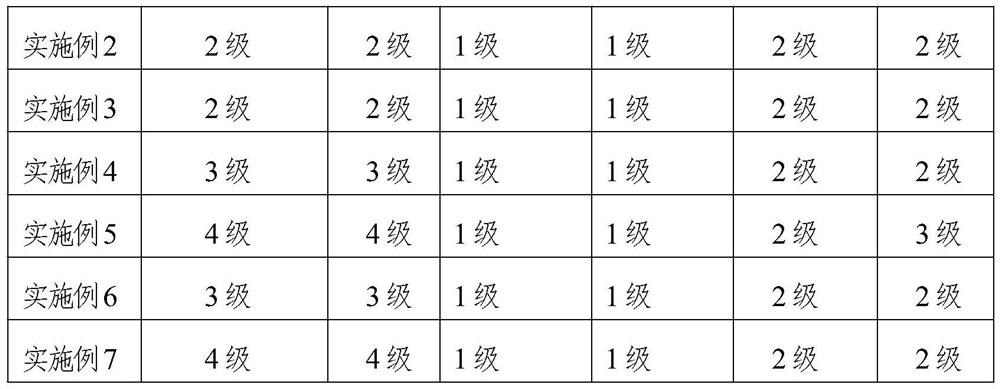

Examples

Embodiment 1

[0041] Present embodiment is a kind of technology that utilizes novel environment-friendly water-based latex coagulant to prepare nitrile coated gloves, and it comprises steps:

[0042] S1: 20 parts by mass of acrylamide (gel monomer), 2 parts by mass of ammonium persulfate (initiator), 2 parts by mass of ferrous chloride (reducing agent), 5 parts by mass of N, N-methylenebispropylene Amide (crosslinking agent), 1 mass part of sodium carboxymethylcellulose (thickener), 3 mass parts of calcium chloride (destabilizer), 67 mass parts of water are mixed, and the pH is adjusted with ammonia water (neutralizer) Stir evenly at 9.30°C to prepare a new type of environmentally friendly water-based coagulant.

[0043] S2: put the polyester flat glove embryo on the hand mold, and raise the temperature to 80°C.

[0044] S3: Soak the glove embryo heated in S2 with the coagulant in S1, shake the water 10 times, and homogenize the water for 3 minutes.

[0045] S4: impregnation with pre-vulc...

Embodiment 2

[0050] Present embodiment is a kind of technology that utilizes novel environment-friendly water-based latex coagulant to prepare natural rubber wrinkled gloves, and it comprises steps:

[0051] S1: 25 parts by mass of acrylamide (gel monomer), 3 parts by mass of ammonium persulfate (initiator), 3 parts by mass of ferrous chloride (reducing agent), 5 parts by mass of N, N-methylenebispropylene Amide (crosslinking agent), 1 part by mass of sodium polyacrylate (thickener), 3 parts by mass of calcium nitrate (destabilizer), and 60 parts by mass of water are mixed, 0.5 part of sodium hydroxide is used to adjust the pH to 7, and stirred at 30°C Evenly, a new type of environmentally friendly water-based coagulant is prepared.

[0052] S2: put the polyester flat glove embryo on the hand mold, and raise the temperature to 70°C.

[0053] S3: Soak the glove embryo heated in S2 with the coagulant in S1, shake the water 10 times, and homogenize the water for 3 minutes.

[0054] S4: impr...

Embodiment 3

[0060] Present embodiment is a kind of technology that utilizes novel environment-friendly water-based latex coagulant to prepare natural rubber coated gloves, and it comprises steps:

[0061] S1: 20 parts by mass of vinyl alcohol (gel monomer), 1.5 parts by mass of ammonium persulfate (initiator), 2 parts by mass of ferrous chloride (reducing agent), 5 parts by mass of N, N-methylenebispropylene Amide (crosslinking agent), 2 parts by mass of sodium polyacrylate (thickener), 2 parts by mass of calcium nitrate (destabilizer), and 67.5 parts by mass of water are mixed, 0.5 part of sodium hydroxide is used to adjust the pH to 7, and stirred at 30°C Evenly, a new type of environmentally friendly water-based coagulant is prepared.

[0062] S2: Put the polyester fully and half-soaked glove embryo on the hand mold, and raise the temperature to 80°C.

[0063] S3: soak the glove embryos heated in S2 with the coagulant in S1, shake the water 20 times, and homogenize the water for 4 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com