Solar cell and method for fabricating a solar cell

A technology of solar cells and dielectrics, applied in the field of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

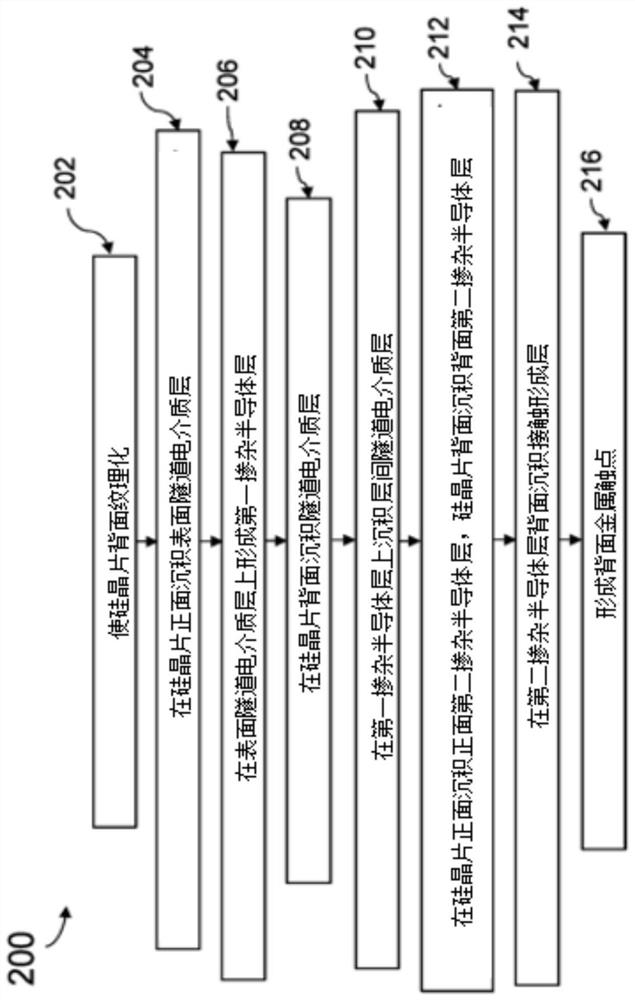

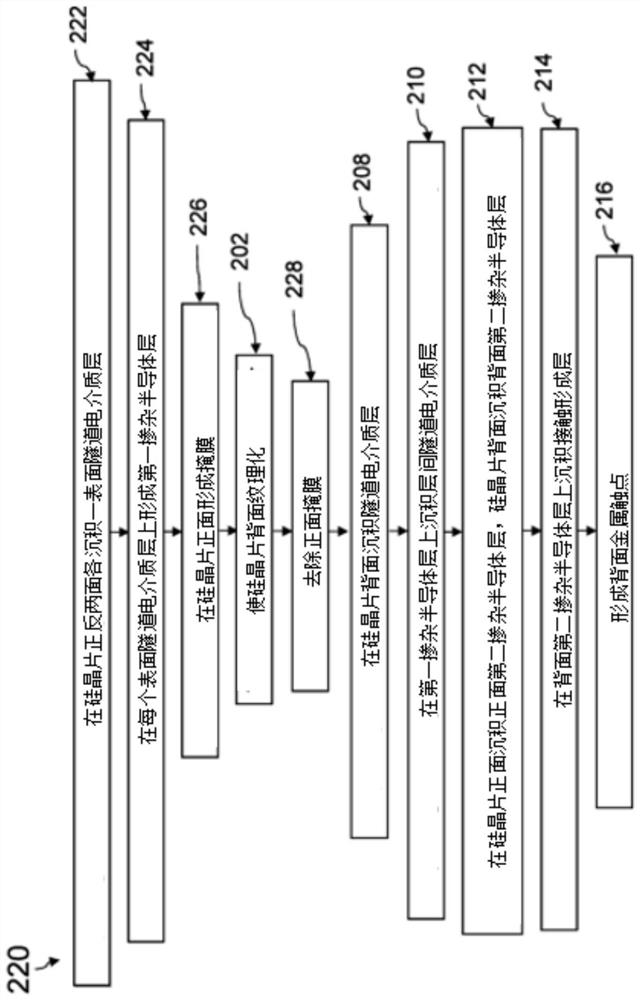

[0059] One embodiment relates to a method for manufacturing a solar cell, in particular a passivated contact solar cell with a tunnel junction.

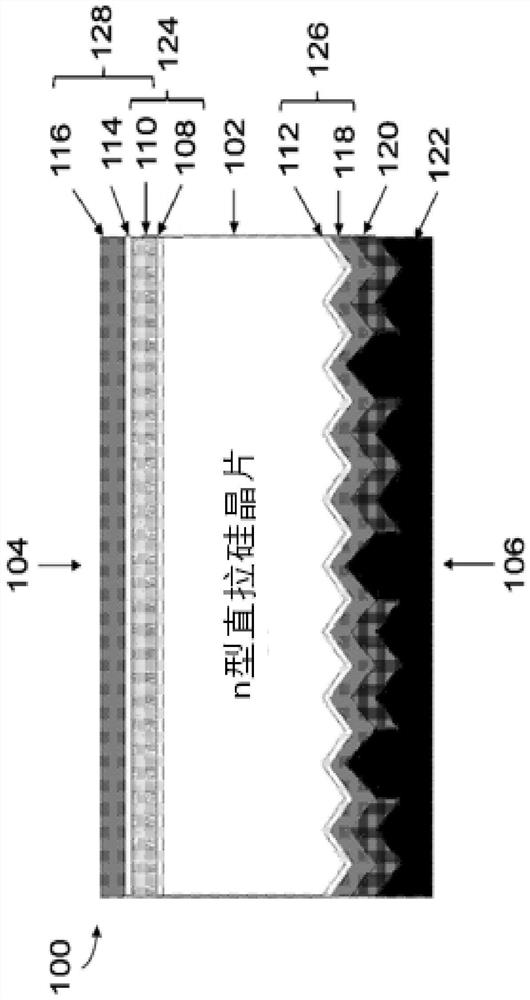

[0060] figure 1 is a structural schematic diagram of a solar cell (100) drawn according to an embodiment. The solar cell (100) can be configured as a high-efficiency silicon bottom cell for integration of tandem thin-film silicon devices, as described below Figure 13 mentioned. Different types of solar cells (100) configured as high-efficiency silicon bottom cells, Figures 11A to 11C The integration of tandem thin-film silicon devices is further discussed.

[0061] A solar cell (100) includes an n-type Czochralski (Cz) grown monocrystalline silicon wafer (102) having a front side (104) and a back side (106). Such as figure 1 As shown, the front side (104) of the silicon wafer (102) has a smooth surface, while the back side (106) of the silicon wafer (102) has a textured surface. A surface tunnel dielectric layer (108) is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com