Seedling cultivating substrate and preparation method thereof

A seedling raising substrate and substrate technology, applied in botany equipment and methods, fertilizer mixture, soilless cultivation, etc., can solve the problems of odor generation, ecological environment pollution, etc. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The tea dregs used in the seedling raising substrate of this example are from Nanjing Rongdian Food Technology Co., Ltd., and the batch of tea dregs is B02-25.

[0031] The specific operation steps of the preparation of the seedling-raising matrix of the present embodiment are as follows:

[0032] A. Tea residue humidity adjustment

[0033] Add a desiccant to the tea dregs with a water content of 75-90% to make the humidity reach 50-60%;

[0034] B. Tea dregs crushing

[0035] The tea dregs after the humidity adjustment in the previous step are directly coarsely crushed to a particle size of less than 5 mm;

[0036] C. Fermentation of tea dregs

[0037] After crushing, 0.5 kg of agricultural microbial fermentation agent is evenly mixed into every cubic tea dregs, and the pile is used for high-temperature aerobic fermentation. The fermentation cycle is 15-40 days. 20 to 30 days, 25 to 40 days in winter, so that the fermented product formed after fermentation of tea d...

Embodiment 20

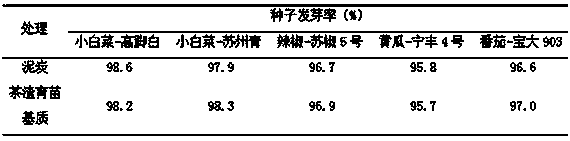

[0051] Take 20 g of the fully fermented tea dregs and peat in this example as two substrates respectively, among which peat is used as the reference substrate, add 200 mL of distilled water, stir thoroughly, and fully extract in a constant temperature shaker at 25°C and 220 rpm. The solution was autoclaved and cooled to room temperature. Vegetable seeds of Chinese cabbage-Gaojiaobai, Chinese cabbage-Suzhouqing, pepper-Sujiao No. 5, cucumber-Ningfeng No. 4, tomato-Bauda 903 are used as seed materials, and peat and tea dregs extract are used respectively As the material, three repetitions were set for each group, and the germination rate of each vegetable seed was counted. The test data are shown in Table 2.

[0052]

[0053] Table 2 Germination rate of vegetable seeds

[0054]

[0055] The results in Table 2 show that the germination rate of various vegetable seeds using tea dregs as a substrate is higher than 95%, and it is determined that tea dregs can be used as a seedl...

Embodiment 2

[0068] The tea dregs used in the seedling raising substrate of this example are from Nanjing Rongdian Food Technology Co., Ltd., and the batch of tea dregs is B02-25.

[0069] The specific operation steps of the preparation of the seedling-raising matrix of the present embodiment are as follows:

[0070] A. Tea residue humidity adjustment

[0071] Add a desiccant to the tea dregs with a water content of 75-90% to make the humidity reach 50-60%;

[0072] B. Tea dregs crushing

[0073] The tea dregs after the humidity adjustment in the previous step are directly coarsely crushed to a particle size of less than 5 mm;

[0074] C. Fermentation of tea dregs

[0075] After crushing, 1.0 kg of agricultural microbial fermentation agent is evenly mixed into every cubic tea dregs to make a stack for high-temperature aerobic fermentation. The fermentation cycle is 15 to 40 days. 20 to 30 days, 25 to 40 days in winter, so that the fermented product formed after the fermentation of tea ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com