Star-wheel oppositely-pried rotor system applied to fermenting machine

A technology of star wheel rotor and fermentation machine, which is applied in the direction of tea treatment before extraction, can solve the problems of long fermentation time, great influence on the technical level of workers, and difficulty in guaranteeing the quality of tea leaves, and achieves the effect of increasing the fermentation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

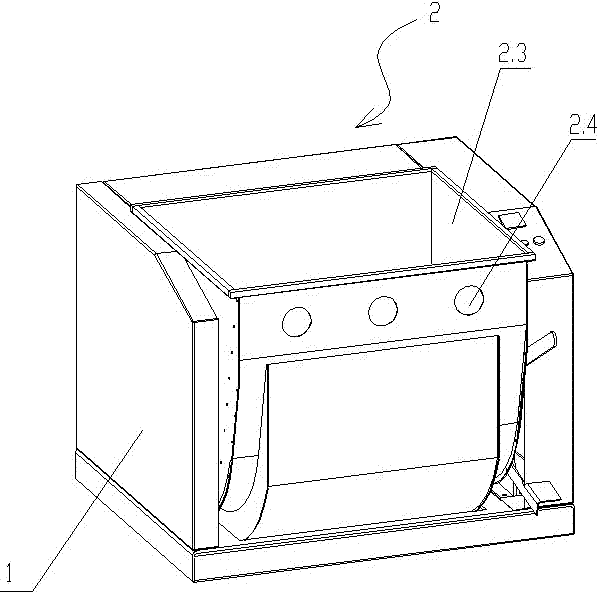

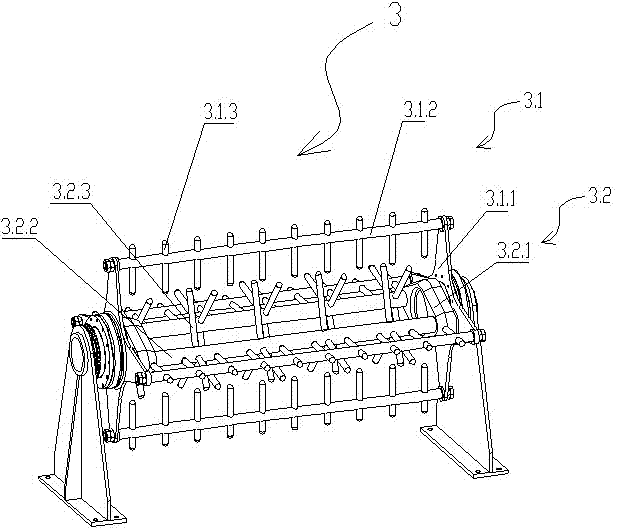

[0024] see Figure 1~6 , the present invention relates to a star wheel pair prying rotor system applied to a fermentation machine, the fermentation machine includes a frame 1, a box body 2 erected on the frame 1, and a star wheel pair installed in the box body 2 Pry rotor system 3,

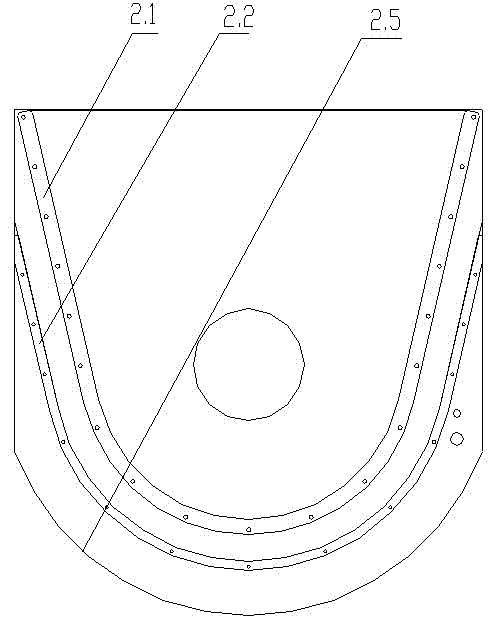

[0025] see figure 1 and figure 2 , the inner shell 2.1 and the outer shell 2.2 contained in the box body 2 are both arranged in a "U" shape. The openings at both ends face the left and right sides respectively), the inner shell 2.1 is placed above the outer shell 2.2, and a U-shaped air passage is formed between the inner shell 2.1 and the outer shell 2.2, and the left and right opening ends of the inner shell 2.1 and the outer shell 2.2 are set There are side plates 2.3, so that the inner shell 2.1 and the left and right side plates 2.3 form a material cavity, and the inner shell 2.1, the outer shell 2.2 and the two left and right side plates 2.3 form a sealed U-shaped air passage. The outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com