Silicon wafer cutting machine

A silicon wafer cutting and cutting machine technology, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of poor ability of sticky tape cutting abrasive fluid, affecting the production efficiency of cutting silicon wafers, etc., to increase the hardness , Improve the cutting effect, improve the effect of cutting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is further described below.

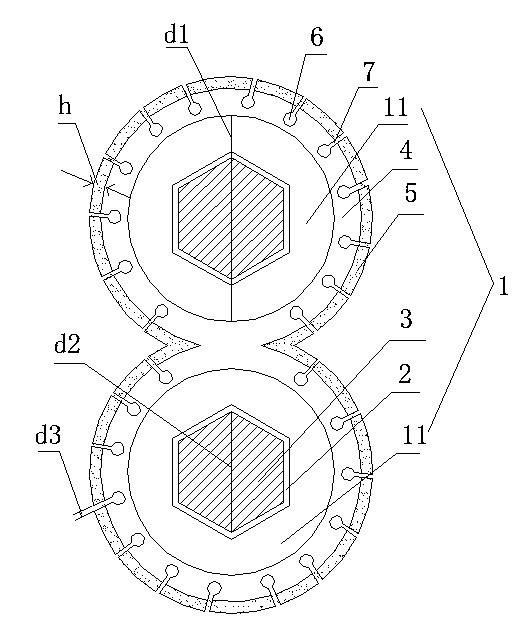

[0013] As shown in the figure, a silicon wafer cutting machine includes a silicon wafer cutting steel wire 1. The silicon wafer cutting steel wire 1 includes two steel wire bodies 11, and the diameter d1 of the steel wire body 11 is 0.3-0.6mm. The two steel wire bodies 11 are an integrated structure that is superimposed on each other to form an "8" shape. The steel wire body 11 is provided with a channel 2. The cross-sectional shape of the channel 2 is a regular hexagon, and the diameter d2 of its circumscribed circle is 0.15- 0.25mm, the channel 2 is filled with hard alloy 3, the outer surface of the steel wire body 11 is covered with a protective layer 4 made of high manganese steel, the thickness h of the protective layer 4 is 0.2-0.3mm, The surface of the protective layer is frosted 5, the protective layer 4 is provided with a liquid storage bag 6, the liquid storage bag 6 is a spherical structure, and the outer wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com