trash can

A garbage bin and box technology, applied in the field of sanitation machinery, can solve the problems of sewage retention, easy blockage of drainage holes on the bottom plate, and inability to drain sewage in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

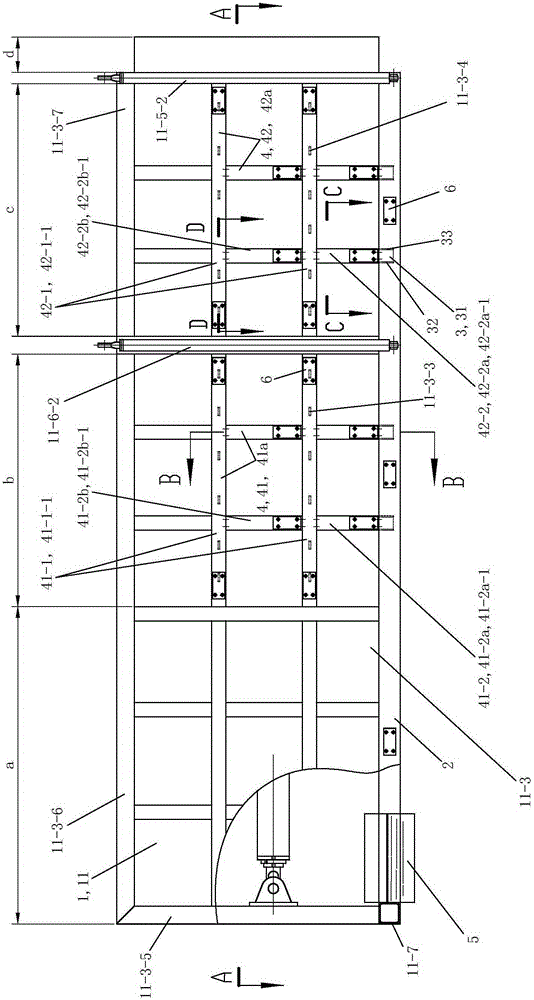

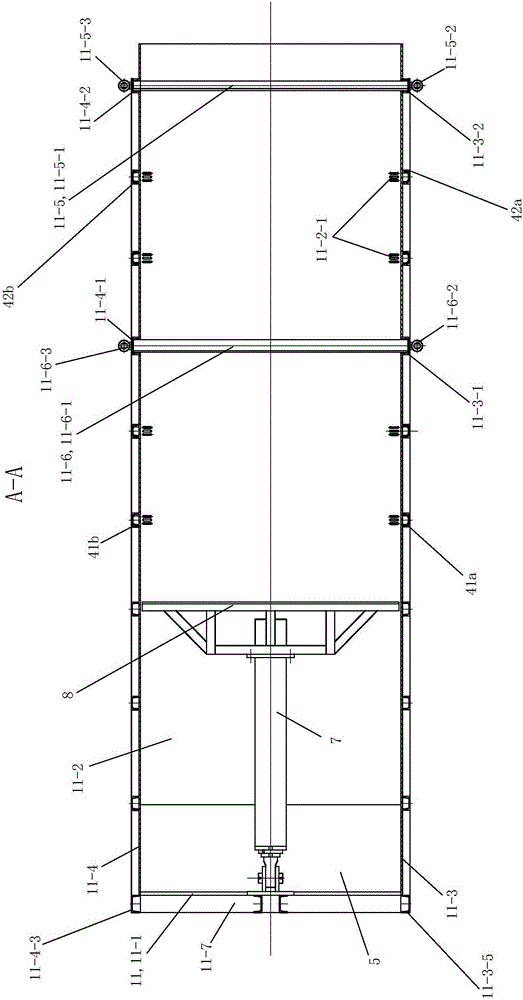

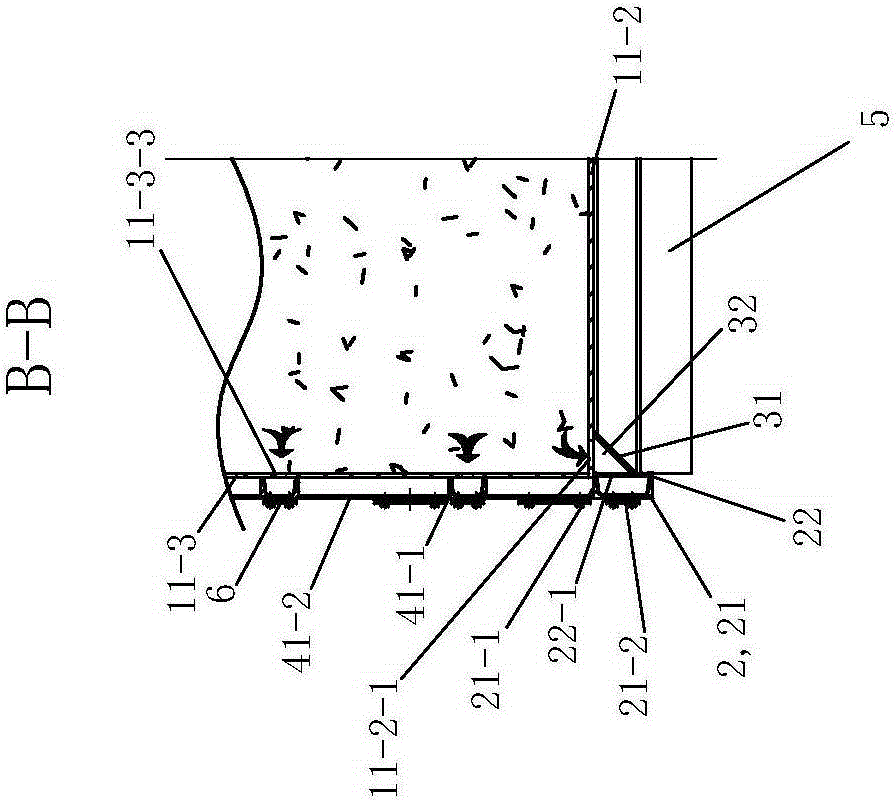

[0066] See figure 1 and figure 2 , The garbage bin 1 of the present invention includes a box body 11, a sewage conveying assembly 2, a bottom sewage collection assembly 3, a side sewage collection assembly 4, a sewage storage device 5, a cleaning assembly 6, a compression cylinder 7 and a pusher plate 8.

[0067] See figure 1 and figure 2 , The box body 11 is sequentially provided with a push plate bin a, a compression bin b, a storage bin c and a discharge port d from left to right.

[0068] The box body 11 includes a left box panel 11-1, a box bottom panel 11-2, a front side panel 11-3, a rear side panel 11-4, an upper sealing panel, a discharge door assembly 11-5, and a compression chamber partition assembly 11- 6 and the left beam 11-7.

[0069] The left cross beam 11-7 is a steel square tube. The left cross beam 11-7 is arranged horizontally along the front and rear directions. The left box board 11-1 is vertically fixedly arranged on the upper side of the left cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com