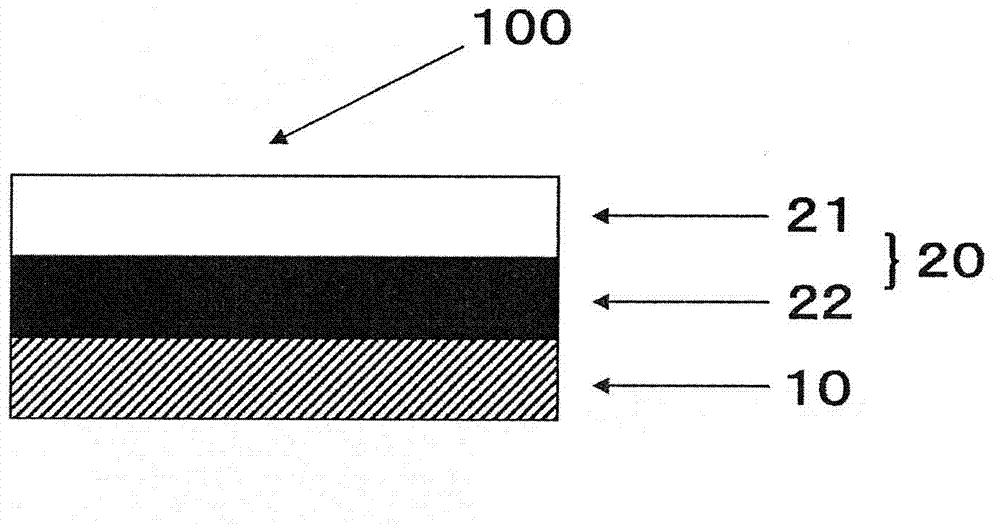

Surface protective sheet

A technology of protective sheet and substrate layer, which is applied in the direction of film/sheet adhesive, adhesive additive, polymer adhesive additive, etc., which can solve the problem of poor adhesion, peeling or cracking, and failure to express adhesion Sexuality and other issues, to achieve high adhesion, adequate and moderate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

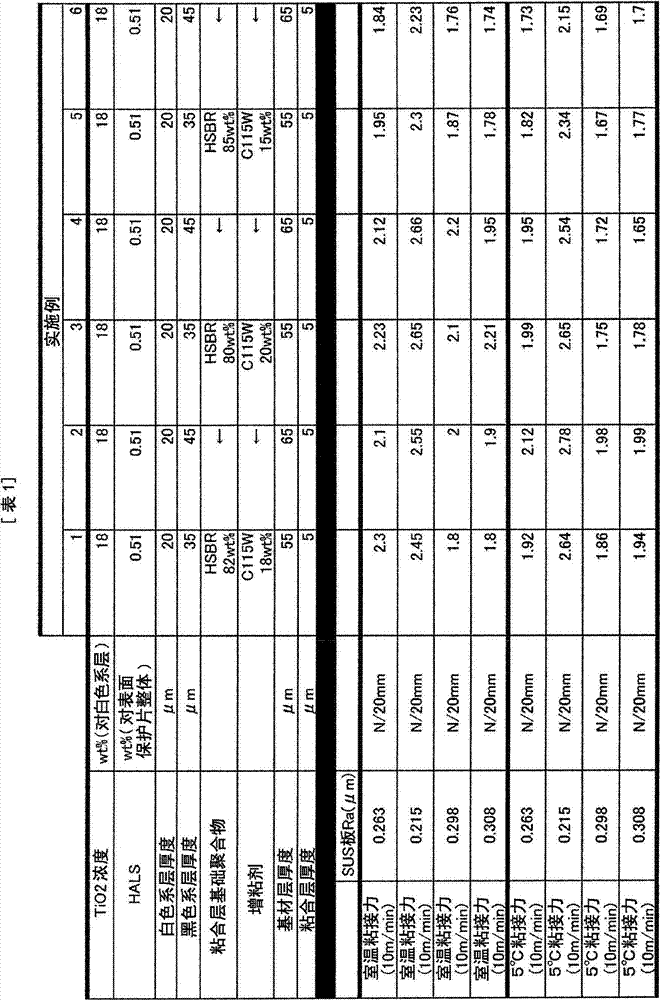

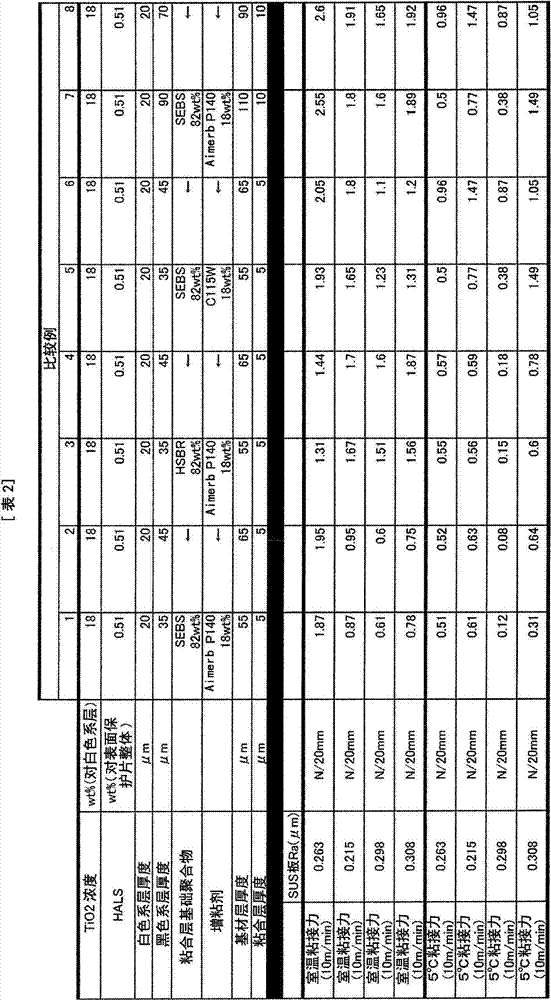

[0100] Relatively low-density polyethylene (manufactured by Tosoh, trade name: Petrothene 186R, density = 0.924 g / cm 3 ), a white pigment (titanium oxide, manufactured by Dupont, trade name: Ti-PureR103), and a hindered amine light stabilizer (HALS, manufactured by BASF, trade name: Tinuvin783) were blended in the content ratio shown in Table 1 to obtain a white layer-forming material .

[0101] Next, with respect to the low-density polyethylene (manufactured by Tosoh, trade name: Petrothene 186R, density=0.924g / cm 3 ) 85% by weight and linear low-density polyethylene (manufactured by Sumitomo Chemical, trade name: ExcellenFXFX307, density=0.890g / cm 3 ) 10% by weight of carbon black MB (manufactured by Sumika Color, trade name: BlackSPEMB-865, carbon content 20%) 5% by weight was blended to obtain a black layer forming material.

[0102] Furthermore, 82% by weight of HSBR (styrene content = 10% by weight, manufactured by JSR, trade name: Dynaron 1321P) and a tackifier (C 5 s...

Embodiment 2

[0106] The thickness of the black-based layer is set to 45 μm, except that, it is carried out in the same manner as in Example 1 to obtain a surface protection sheet (2) (thickness: white layer) with a three-layer structure (white-based layer / black-based layer / adhesive layer). System layer / Black system layer / Adhesive layer=20μm / 45μm / 5μm).

[0107] The results are shown in Table 1.

Embodiment 3

[0109] The blending ratio of HSBR was set to 80% by weight, and the blending ratio of the tackifier was set to 20% by weight, except that, it was carried out in the same manner as in Example 1, and the three-layer structure (white layer / black layer / Adhesive layer) surface protection sheet (3) (thickness: white layer / black layer / adhesive layer=20 μm / 35 μm / 5 μm).

[0110] The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com