Solar water tank water-saving type liquid level controlling method

A solar water tank and liquid level control technology, applied in solar thermal power generation, solar thermal devices, heating devices, etc., can solve problems such as danger, easy damage, waste of hot water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

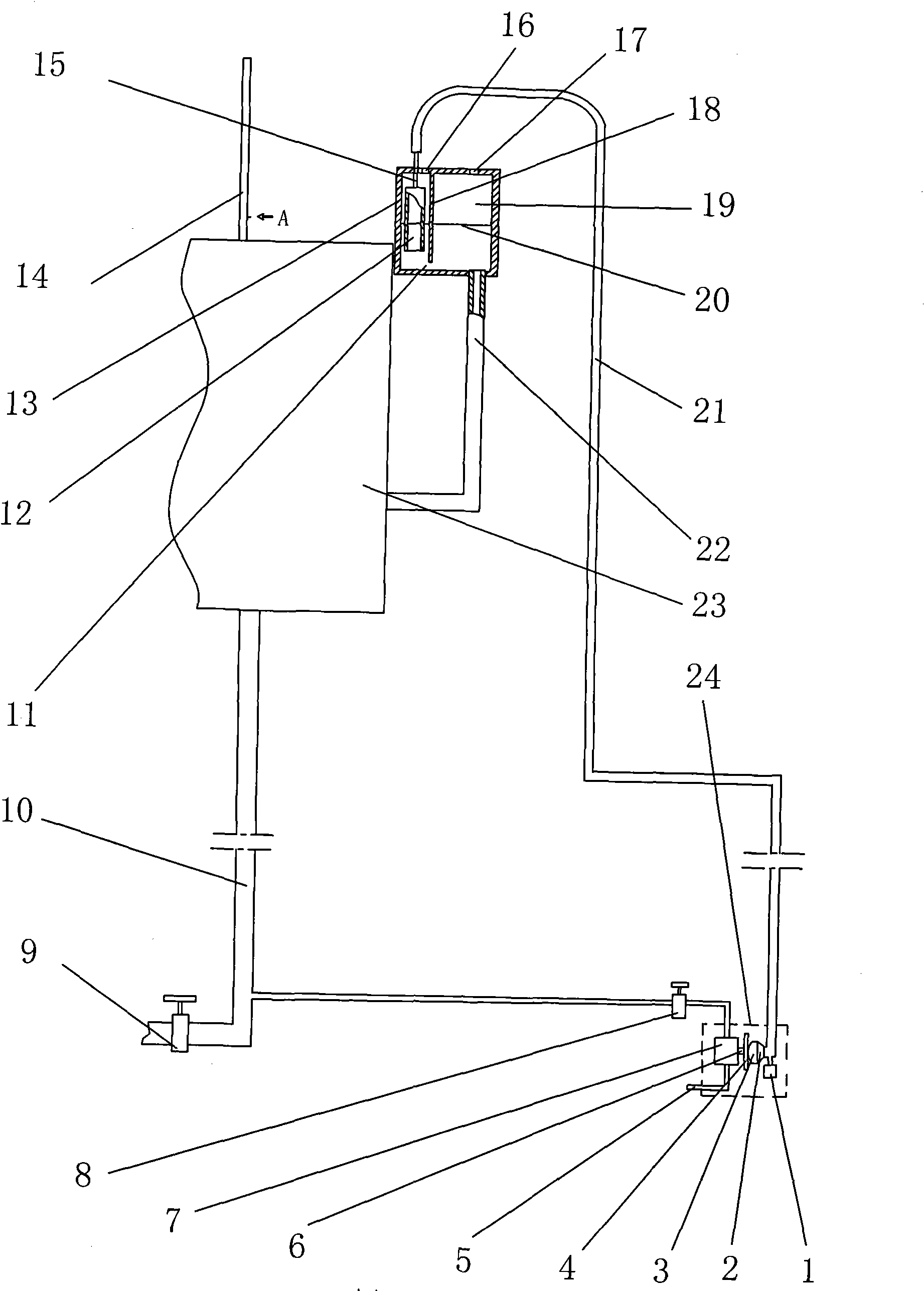

[0007] figure 1 Among them, 1 is the hydrophobic screw cap, 2 is the seat of the air bag, 3 is the membrane of the air bag, 4 is the pressure piece, 5 is the inlet pipe, 6 is the pressure rod on the small flow micro-valve, 7 is the small-flow micro-valve, 8 is the water outlet valve, 9 is the water valve, 10 is the water pipe, 11 is the bottom seam, 12 is the air pressure pipe, 13 is the high liquid level control box, 14 is the air discharge pipe, 15 is the air pressure connecting pipe, 16 is the left ventricle Air hole, 17 is the vent hole in the right chamber, 18 is the steam partition, 19 is the overflow tank, 20 is the compressed air water level line, 21 is the air pressure transmission pipe, 22 is the water guide pipe, 23 is the water tank, 24 is the water tank inlet pipe, 25 refers to The dotted line in represents the pneumatic valve device composed of the above-mentioned 1, 2, 3, 4, 5, 6, and 7 components. figure 1 The middle deflation pipe 14 and the water guide pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com