Silicon carbide ceramic heat exchanger

A technology of silicon carbide ceramics and heat exchangers, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve problems such as equipment failure, small thermal expansion coefficient, and thermal conductivity limiting heat exchange efficiency. Achieve the effects of low replacement times and costs, consistent thermal expansion coefficients, and remarkable energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

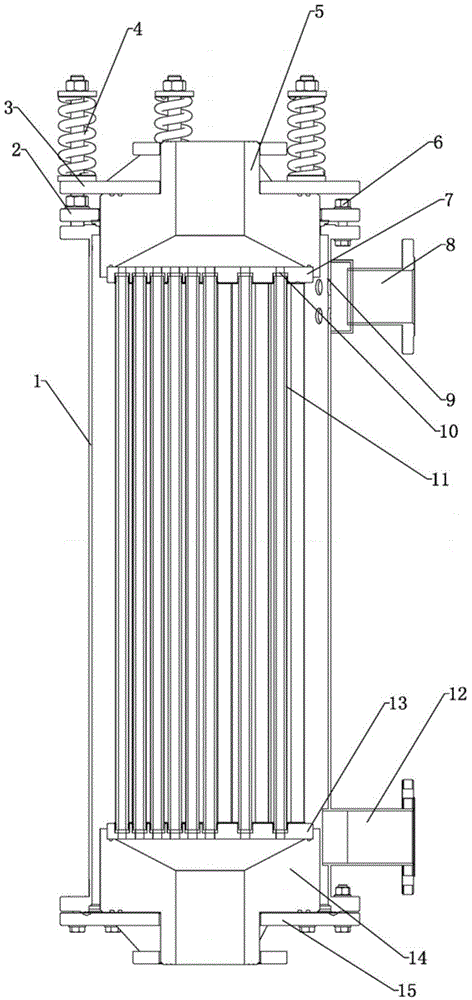

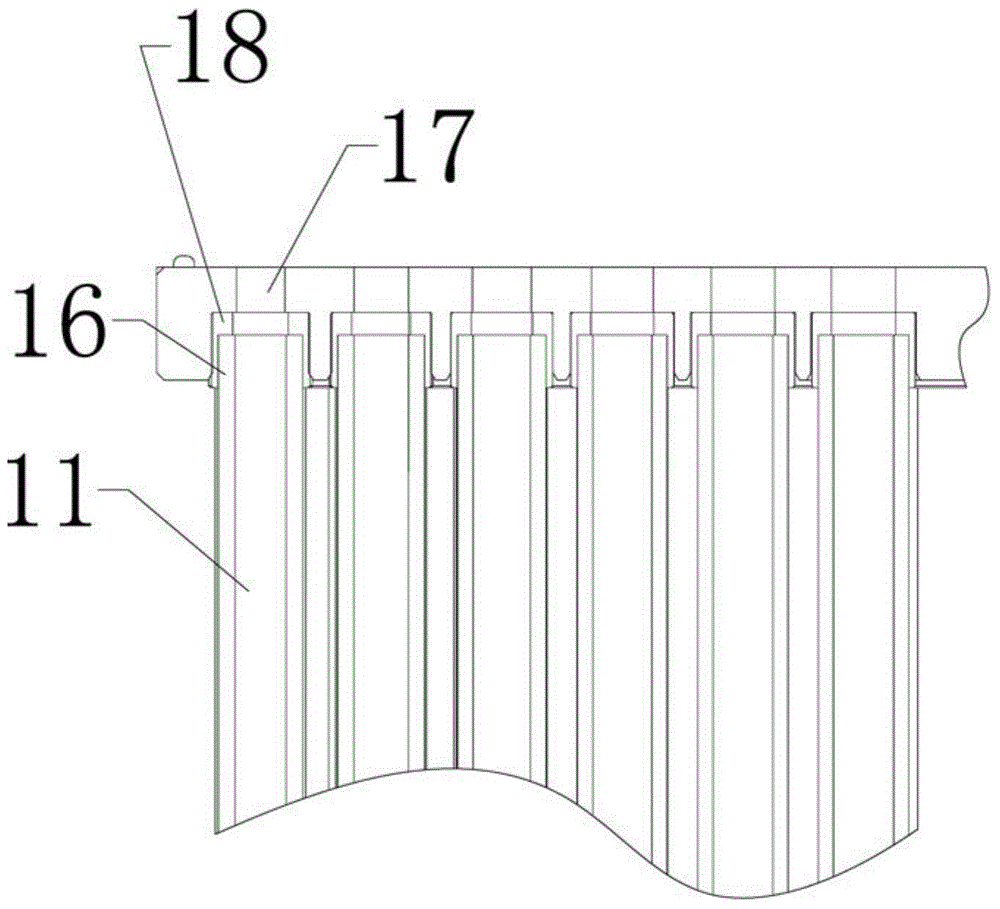

[0026] like Figure 1-2 The silicon carbide ceramic heat exchanger shown includes a silicon carbide ceramic upper blocking plate 7, a silicon carbide ceramic lower blocking plate 13, a silicon carbide ceramic heat exchange tube bundle 11, an upper collecting port 5, a lower collecting port 14 and a stainless steel shell 1 , the silicon carbide ceramic heat exchange tube bundle 11 is arranged in the shell 1, the silicon carbide ceramic upper blocking plate 7 and the silicon carbide ceramic lower blocking plate 13 are provided with stepped holes 10, and the silicon carbide ceramic heat exchange tube bundle 10 is The hole diameter on one side of 11 is larger than the hole diameter on the other side. The two ends of the silicon carbide ceramic heat exchange tube bundle 11 are respectively connected to the upper blocking plate 7 of silicon carbide ceramics and the lower blocking plate 13 of silicon carbide ceramics through the stepped holes 10. The blocking plate 7 is connected wit...

Embodiment 2

[0035]A silicon carbide ceramic heat exchanger, comprising a silicon carbide ceramic upper blocking plate 7, a silicon carbide ceramic lower blocking plate 13, a silicon carbide ceramic heat exchange tube bundle 11, an upper collection port 5, a lower collection port 14 and a shell 1, the The silicon carbide ceramic heat exchange tube bundle 11 is arranged in the shell 1, the silicon carbide ceramic upper blocking plate 7 and the silicon carbide ceramic lower blocking plate 13 are provided with stepped holes 10, and the silicon carbide ceramic heat exchange tube bundle 10 described in the stepped hole 11— The aperture on one side is larger than the aperture on the other side, and the two ends of the silicon carbide ceramic heat exchange tube bundle 11 are respectively connected to the upper blocking plate 7 of silicon carbide ceramics and the lower blocking plate 13 of silicon carbide ceramics through the stepped holes 10, and the upper blocking plate of silicon carbide ceramics...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com