Automobile crossbeam assembly hole visual on-line measurement system and method thereof

A technology of automobile girder and measurement system, applied in the field of visual measurement, can solve the problems of burden, low system measurement speed, large number of images, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

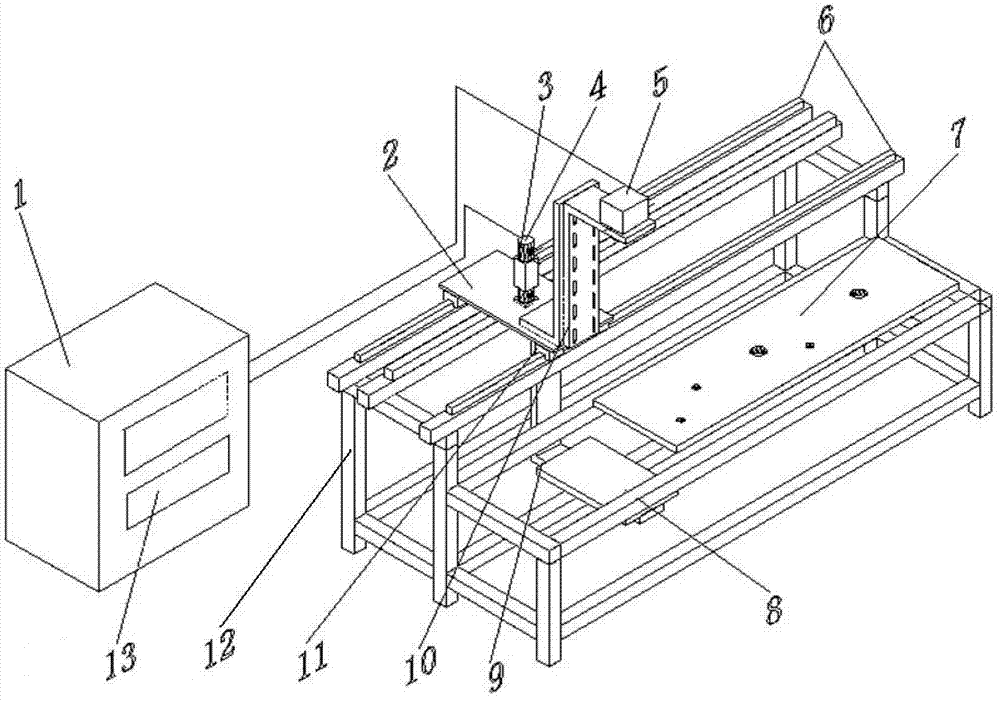

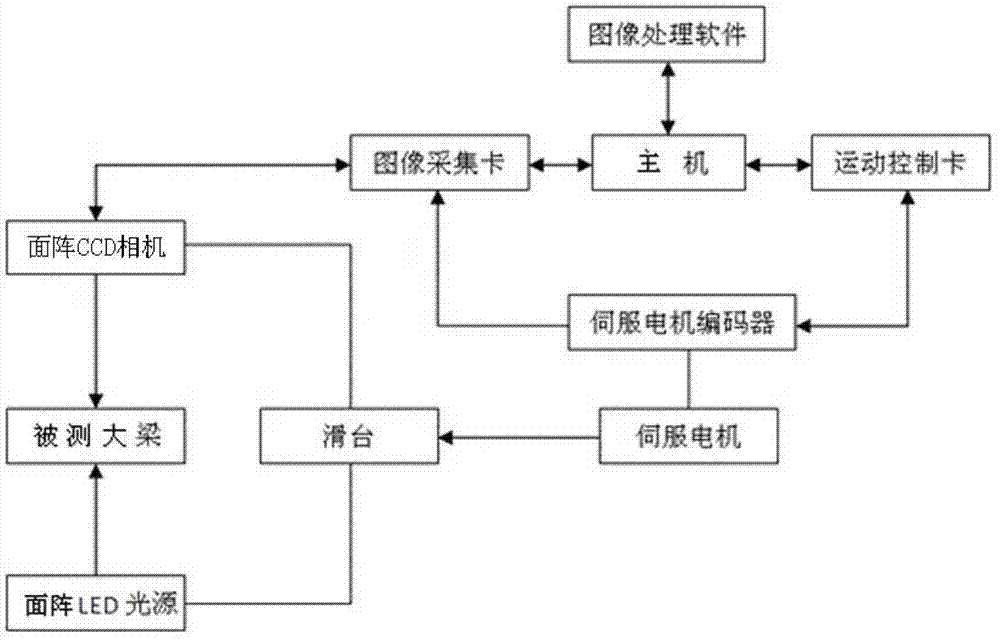

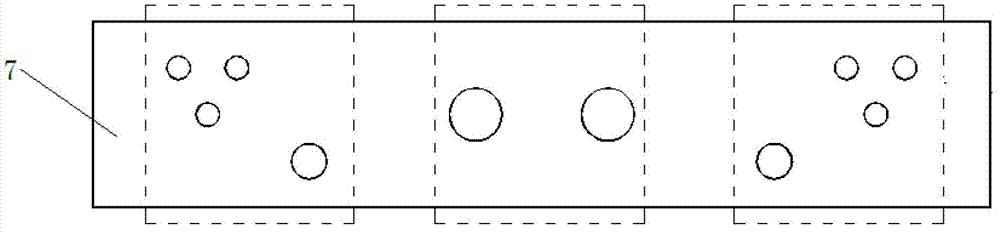

[0053] refer to figure 1 As shown, the visual on-line measurement system for the assembly hole of the automobile frame according to the present invention includes a main console 1, a servo motor 3, a servo motor encoder 4, a slide table 2, a slider 11, a horizontal slide rail 6, and a fixed height frame 12 , the video camera 5 and the measured girder 7, the main console 1 is provided with a host 13, the PCI slot of the host 13 is respectively inserted with a motion control card and an image acquisition card, and the host 13 communicates with the motion control card The servo motor 3 is connected, the servo motor encoder 4 is coaxially connected with the servo motor 3, the servo motor 3 is fixed on the sliding table 2, and the sliding table 2 is connected with the horizontal slide rail 6 through the slider 11, so The slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com