Power split hybrid system mode switching hardware-in-the-loop simulation test bench

A hybrid power system and mode switching technology, applied in electrical testing/monitoring, etc., can solve problems such as difficulty, complex control strategy, and cumbersome configuration process, and achieve the effects of accurate prediction and evaluation, shortened development time, and improved execution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

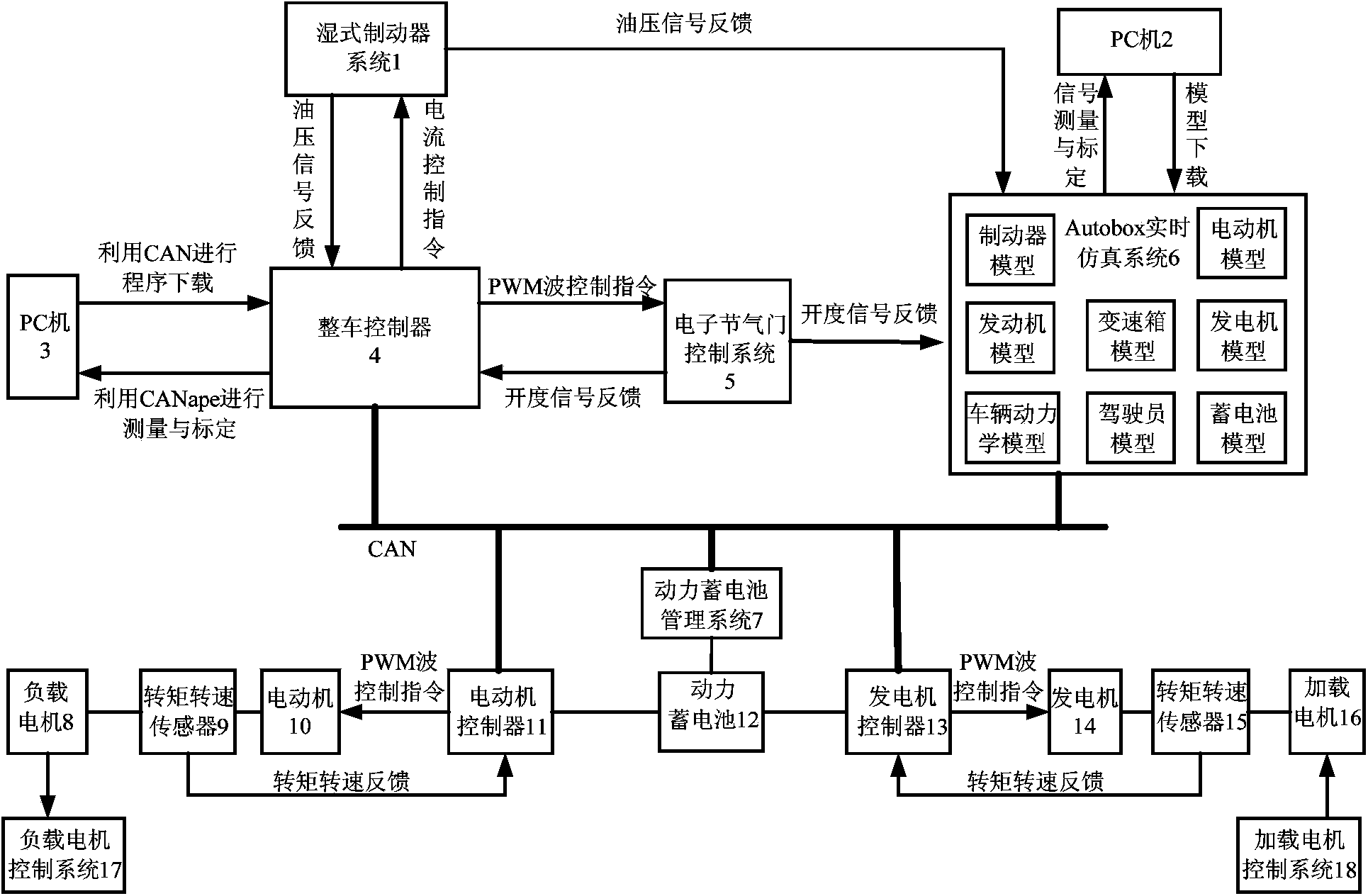

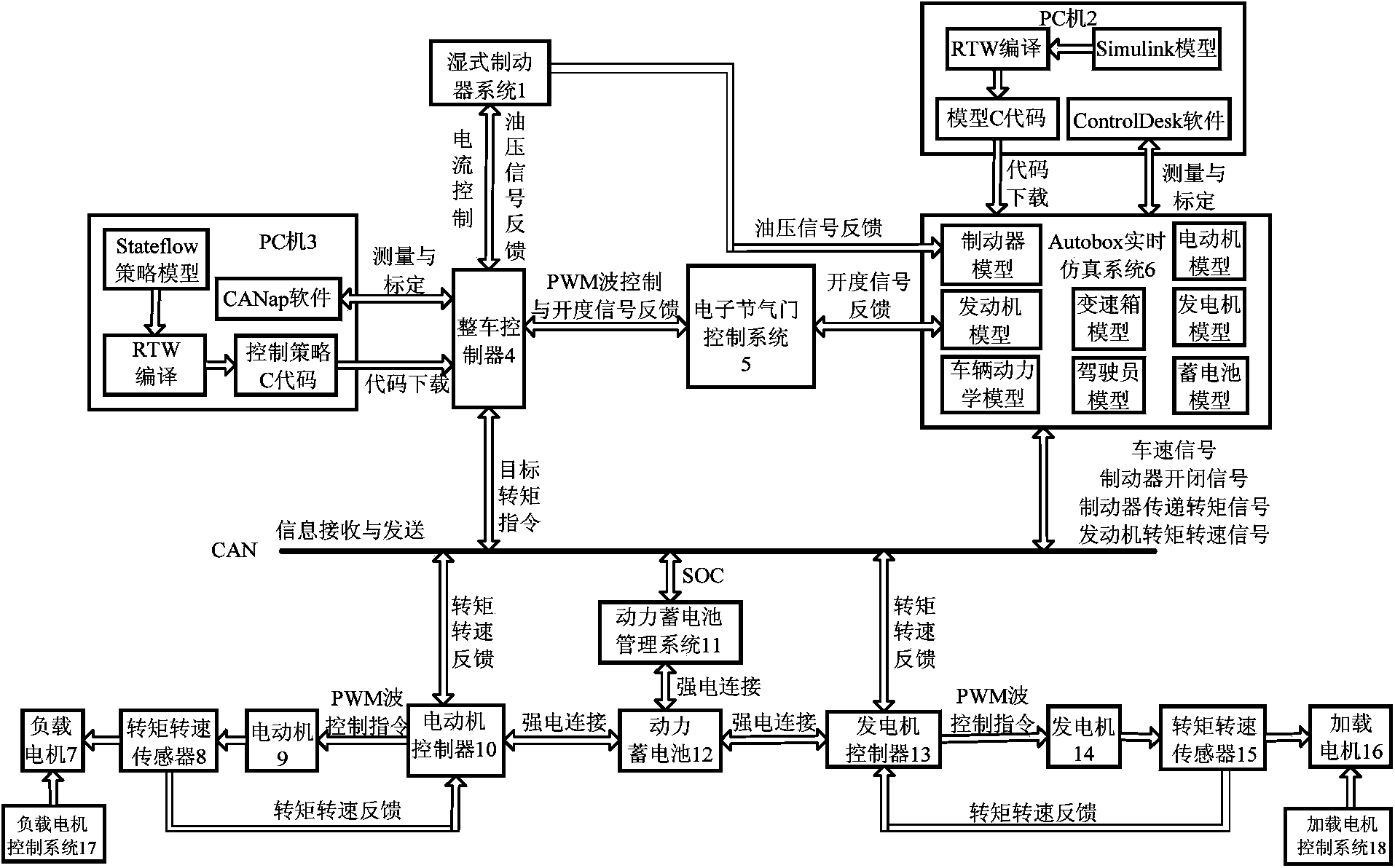

[0040] Such as figure 1 , figure 2 As shown, a hardware-in-the-loop simulation test bench for power-split hybrid system mode switching, including wet brake system 1, PCs 2 and 3, vehicle controller 4, electronic throttle control system 5, and AutoBox real-time simulation system 6. Power battery 12 and power battery management system 11, motor 9 and motor controller 10, generator 14 and generator controller 13, torque speed sensors 8 and 15, load motor 7 and load motor control system 17, load motor 16 and loading motor control system 18. The vehicle controller 4 is respectively con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com