Hydrodynamic retarder and method for controlling the power transmission of such a retarder

A hydraulic reducer and power transmission technology, applied in the field of hydraulic reducer, can solve the problems of unfavorable heat exchanger, increased power loss of hydraulic reducer, high price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

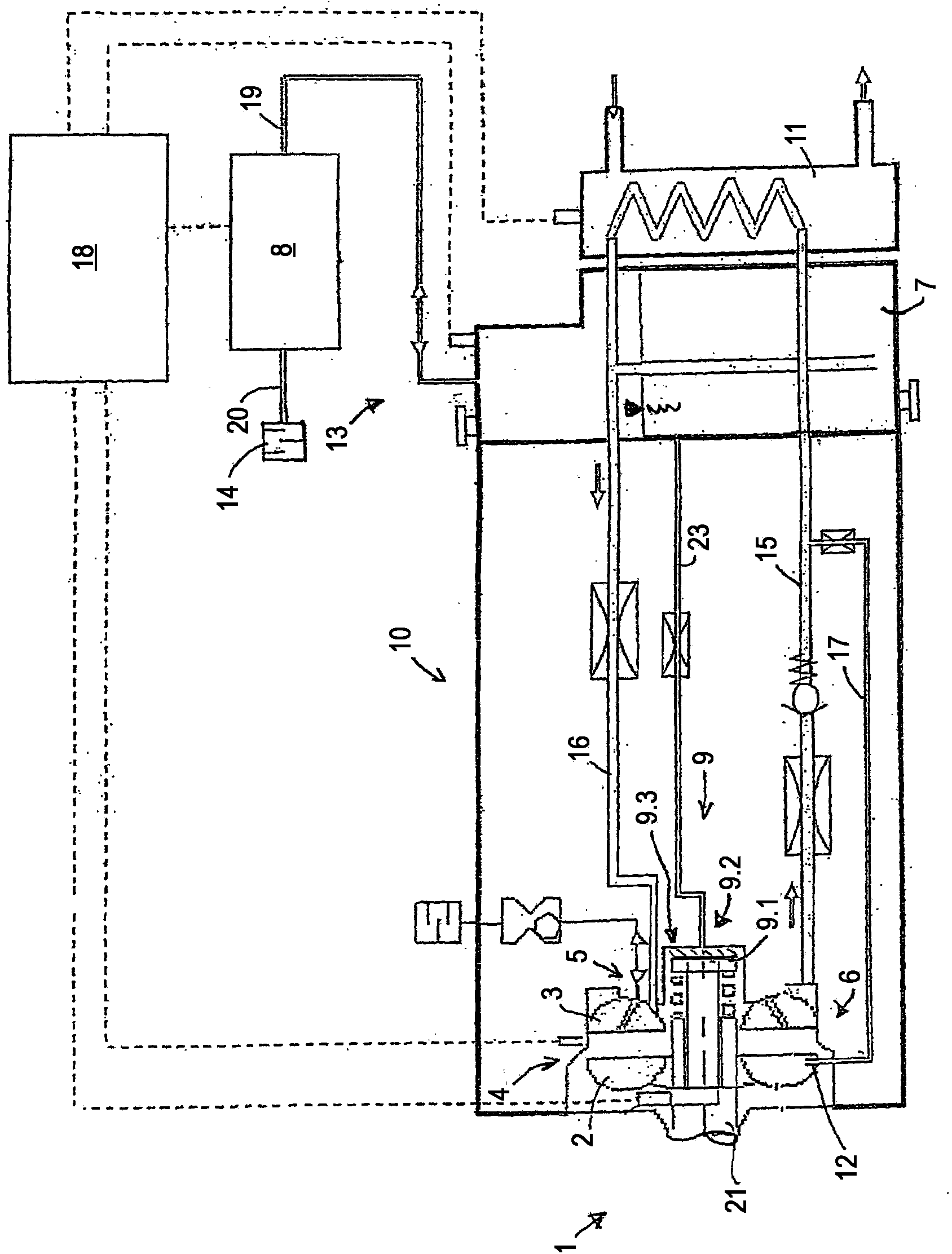

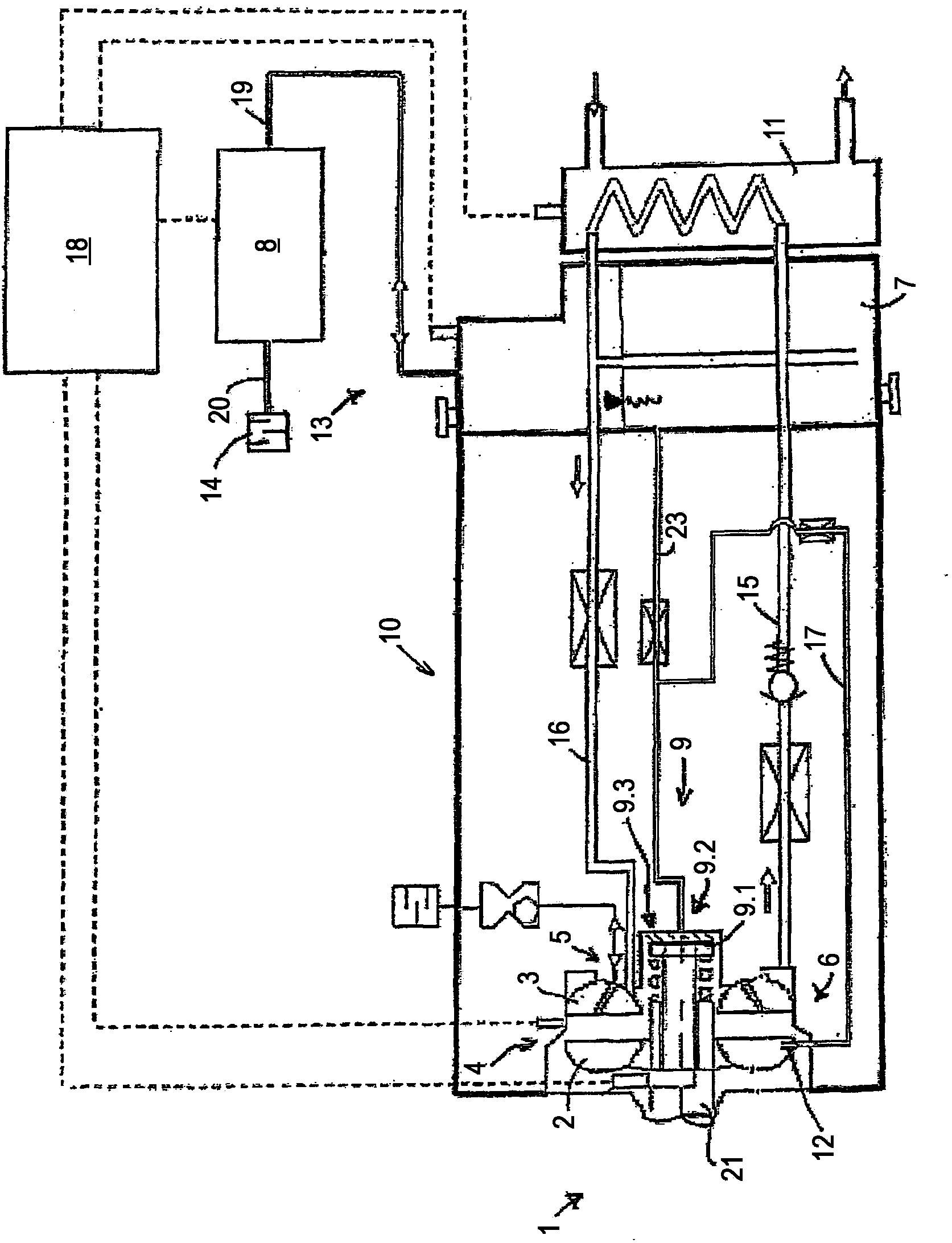

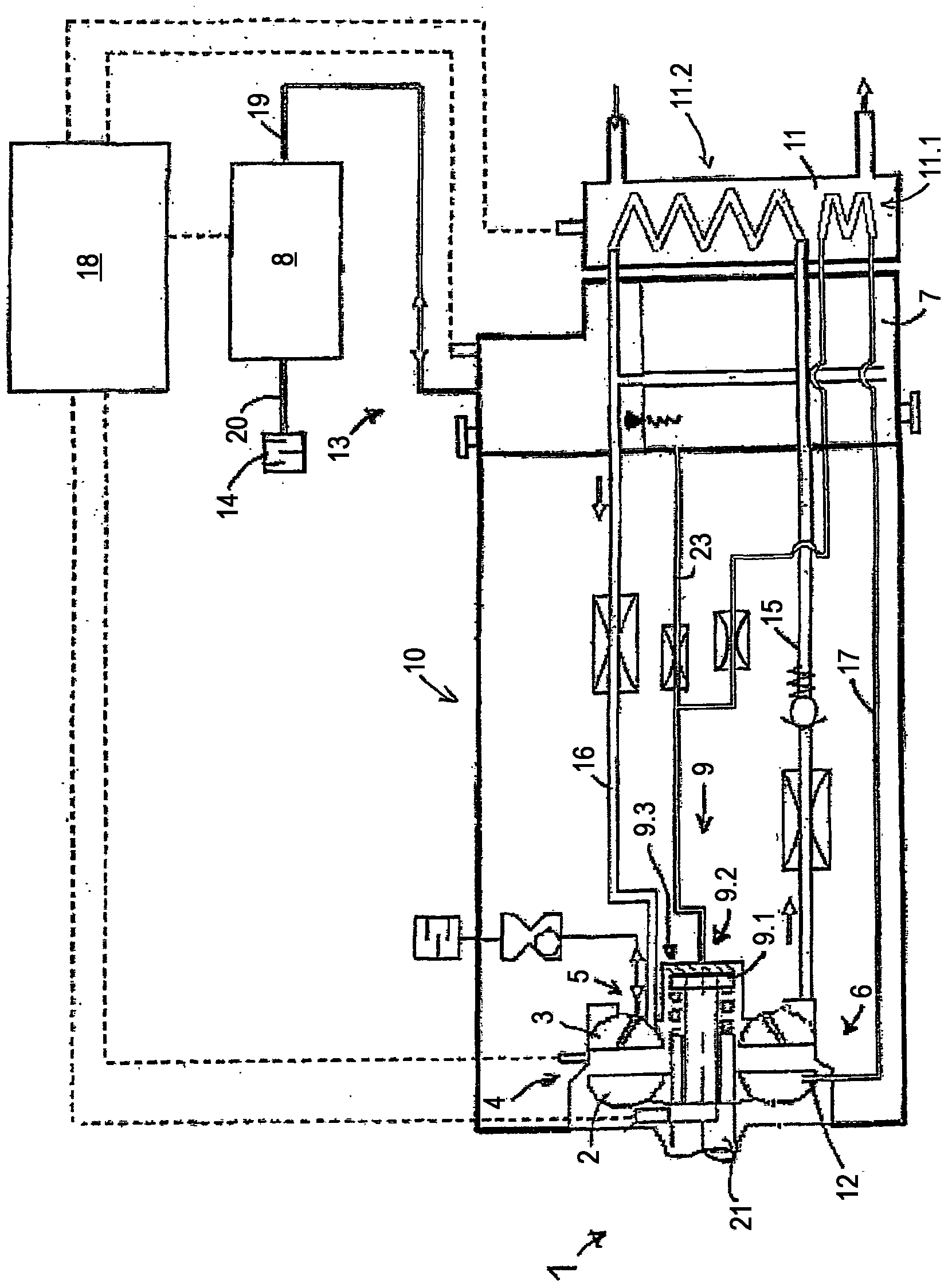

[0040] figure 1 Shown is a hydrodynamic retarder 1 as part of a brake system of a motor vehicle with a working medium-conducting external cooling circuit for dissipating the working medium during braking operation of the hydrodynamic retarder 1 accumulated heat. In the present case, the working medium is oil. However, the hydrodynamic retarder 1 can also be part of the cooling circuit of the vehicle, in which case the working medium can then be water or an aqueous solution.

[0041] as in figure 1 As shown in , in the external cooling circuit, the following components are arranged in the flow direction of the working medium: a hydrodynamic retarder 1, which includes a rotor 2 and a stator 3, which together form a torus-shaped working chamber 4 ; the opening of the first connecting line 15 from the hydraulic retarder 1 to the heat exchanger 11, also called an oil cooler when the working medium is oil; a fixed section with a constant cross section arranged behind the opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com