Electric hair trimmer

A hair clipper and electric technology, applied in metal processing and other directions, can solve the problems of unusable cutter head components, decreased sharpness, increased noise, etc., and achieve the effects of improving haircut efficiency, reducing friction, and reducing load current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

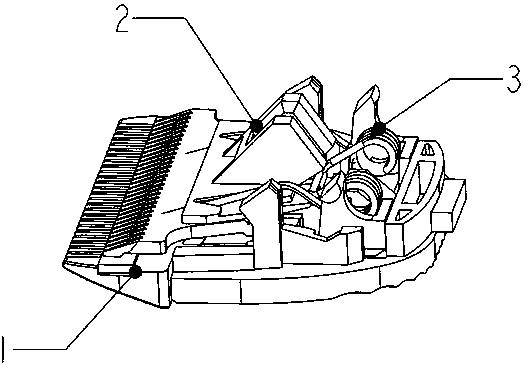

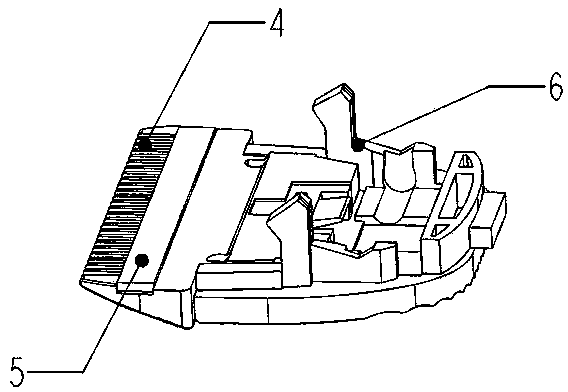

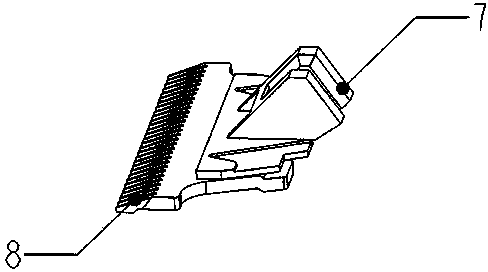

[0030] see Figure 1~7 As shown, an electric hair clipper includes a cutter head assembly, a motor, a rotating shaft and a power supply. The cutter head assembly includes a fixed knife assembly 1, a moving knife assembly 2 and a fine-tuning mechanism 3, and the moving knife assembly is arranged above the fixed knife assembly. The moving knife assembly includes a fixedly connected moving knife 8 and a moving knife driving frame 7; the fine-tuning mechanism includes an adjustment block 9 and a torsion spring 10 arranged on the adjustment block; the two ends of the torsion spring are plugged into the On the driving frame of the moving knife, the moving knife has the freedom of movement of swinging left and right and sliding back and forth relative to the fixed knife assembly; the upper surface of the fixed knife assembly is provided with a grinding bar 5.

[0031] The fixed knife assembly includes a fixed frame 6 and a fixed knife 4 fixedly connected; the fixed knife is provided ...

Embodiment 2

[0038] see Figure 8 As shown, an electric hair clipper includes a cutter head assembly, a motor, a rotating shaft and a power supply, the cutter head assembly includes a fixed knife assembly, a moving knife assembly and a fine-tuning mechanism, and the moving knife assembly is arranged above the fixed knife assembly; The movable knife assembly includes a fixedly connected movable knife and a movable knife drive frame; the fine-tuning mechanism includes an adjustment block and a torsion spring arranged on the adjustment block; the two ends of the torsion spring are plugged into the movable knife drive frame, The movable knife has the freedom of swinging left and right and sliding back and forth relative to the fixed knife assembly; the upper surface of the fixed knife assembly is provided with a grinding layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com